by Eric Meier

When attempting to identify a wood sample, it’s important to keep in mind the limitations and obstacles that are present in our task. Before starting, please have a look at The Truth Behind Wood Identification to approach the task in a proper mindset; I consider the linked article to be required reading for all those visiting my site with the intent of identifying wood.

1. Confirm it is actually solid wood.

Before proceeding too much farther into the remaining steps, it’s first necessary to confirm that the material in question is actually a solid piece of wood, and not a man-made composite or piece of plastic made to imitate wood.

Can you see the end-grain?

Manufactured wood such as MDF, OSB, and particleboard all have a distinct look that is—in nearly all cases—easily distinguishable from the endgrain of real wood. Look for growth rings—formed by the yearly growth of a tree—which will be a dead-giveaway that the wood sample in question is a solid, genuine chunk of wood taken from a tree.

Is it veneered?

If you see a large panel that has a repeating grain pattern, it may be a veneer. In such cases, a very thin layer of real wood is peeled from a tree and attached to a substrate; sometimes the veneer can be one continuous repeating piece because it is rotary-sliced to shave off the veneer layer as the tree trunk is spun by machines. Assuming it is a real wood veneer with a distinct grain and texture—and not merely a piece of printed plastic—you may still be able to identify the outer veneer wood in question, but you should still realize that is it only a veneer and not a solid piece of wood.

Is it painted or printed to look like wood?

Many times, especially on medium to large-sized flat panels for furniture, a piece of particleboard or MDF is either laminated with a piece of wood-colored plastic, or simply painted to look like wood grain. Many of today’s interior hardwood flooring planks are good examples of these pseudo-wood products: they are essentially a man-made material made of sawdust, glues, resins, and durable plastics.

2. Look at the color.

Some questions to immediately ask yourself:

Is the color of the wood natural, or is it stained?

If there is even a chance that the color isn’t natural, the odds are increased that the entire effort of identifying the wood will be in vain.

Is it weathered or have a patina?

Many woods, when left outside in the elements, tend to turn a bland gray color. Also, even interior wood also takes on a patina as it ages: some woods get darker, or redder, and some even get lighter or lose their color; but for the most part, wood tends to darken with age.

Is it possible to sand or plane the board to see the natural raw color of the wood?

The most predictable baseline to use when identifying wood is in a freshly sanded state. This eliminates the chances of a stain or natural aging skewing the color diagnosis of the wood.

3. Observe the wood grain.

If the wood is unfinished, then look at the texture of the grain. Ask yourself these questions:

Does the wood have an open, porous texture?

Most softwoods will be almost perfectly smooth with no grain indentations, while many common hardwoods have an open pore structure, such as oak or mahogany; though there are some hardwoods that are also smooth to the touch, such as maple.

Can you tell if the wood is quartersawn or plainsawn?

By observing the grain patterns, many times you can tell how the board was cut from the tree. Some wood species have dramatically different grain patterns from plainsawn to quartersawn surfaces. For instance, on their quartersawn surfaces, lacewood has large lace patterns, oak has flecks, and maple has the characteristic “butcher block” appearance.

Is there any figure or unusual characteristics, such as sapwood, curly or wild grain, burl/knots, etc.?

Some species of wood have figure that is much more common than in other species: for example, curly figure is fairly common in soft maple, and the curls are usually well-pronounced and close together. Yet when birch or cherry has a curly grain, it is more often much less pronounced, and the curls are spaced farther apart.

4. Consider the weight and hardness of the wood.

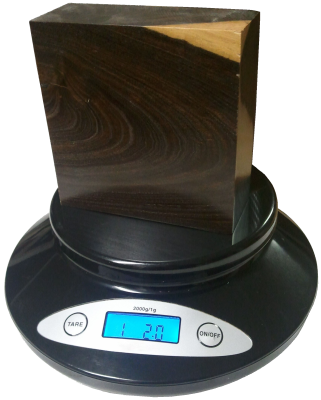

If it’s possible, pick the piece of wood up and get a sense of its weight, and compare it to other known wood species. Try gouging the edge with your fingernail to get a sense of its hardness. If you have a scale, you can take measurements of the length, width, and thickness of the wood, and combine them to find the density of the wood. This can be helpful to compare to other density readings found in the database. When examining the wood in question, compare it to other known wood species, and ask yourself these questions:

Is the wood dry?

Wood from freshly felled trees, or wood that has been stored in an extremely humid environment will have very high moisture contents. In some freshly sawn pieces, moisture could account for over half of the wood’s total weight! Likewise, wood that has been stored in extremely dry conditions of less than 25% relative humidity will most likely feel lighter than average.

How does the wood’s weight compare to other species?

Taking into account the size of the board, how does its weight compare to other benchmark woods? Is it heavier than oak? Is it lighter than pine? Look at the weight numbers for a few wood species that are close to yours, and get a ballpark estimate of its weight.

How hard is the wood?

Obviously softwoods will tend to be softer than hardwoods, but try to get a sense of how it compares to other known woods. Density and hardness are closely related, so if the wood is heavy, it will most likely be hard too. If the wood is a part of a finished item that you can’t adequately weigh, you might be able to test the hardness by gouging it in an inconspicuous area. Also, if it is used in a piece of furniture, such as a tabletop, a general idea of its hardness can be assessed by the number and depth of the gouges/dings in the piece given its age and use. A tabletop made of pine will have much deeper dents than a tabletop made of Oak. Additionally, you can always try the “fingernail test” as a rough hardness indicator: find a crisp edge of the wood, and with your fingernail try to push in as hard as you can and see if you’re able to make a dent in the wood.

5. Consider its history.

Many times we forget common sense and logic when attempting to identify wood. If you’ve got a piece of Amish furniture from Pennsylvania, chances are more likely that the wood will be made of something like black walnut or cherry, and not African wenge or jatoba. You might call it “wood profiling,” but sometimes it can pay to be a little prejudiced when it comes to wood identification. Some common-sense questions to ask yourself when trying to identify a piece of wood:

Where did it come from?

Knowing as much as you can about the source of the wood—even the smallest details—can be helpful. If the wood came from a wood pile or a lumber mill where all the pieces were from trees processed locally, then the potential species are immediately limited. If the wood came from a builder of antique furniture, or a boat-builder, or a trim carpenter: each of these occupations will tend to use certain species of woods much more often than others, making a logical guess much simpler.

How old is it?

As with the wood’s source, its age will also help in identification purposes. Not only will it help to determine if the wood should have developed a natural patina, but it will also suggest certain species which were more prevalent at different times in history. For instance, many acoustic guitars made before the 1990s have featured Brazilian rosewood backs/sides, yet due to CITES restrictions placed upon that species, East Indian rosewood became a much more common species on newer guitars. (And this is a continuing shift as newer replacements are sought for rosewoods altogether.)

How large is the piece of wood?

Some species of trees are typically very small—some are even considered shrubs—while others get quite large. For instance, if you see a large panel or section of wood that’s entirely black, chances are it’s either painted, dyed, or stained: Gaboon ebony and related species are typically very small and very expensive.

What is the wood’s intended use?

Simply knowing what the wood was intended for—when considered in conjunction with where it came from and how old it is—can give you many clues to help identify it. In some applications, certain wood species are used much more frequently than others, so that you can make an educated guess as to the species of the wood based upon the application where it was used. For instance, in the United States: many older houses with solid hardwood floors have commonly used either red oak or hard maple; many antique furniture pieces have featured quartersawn white oak; many violins have spruce tops; many closet items used aromatic red cedar, and so forth. While it’s not a 100% guarantee, “profiling” the wood in question will help reduce the number of possible suspects, and aid in deducing the correct species.

6. Find the X-Factor.

Sometimes, after all the normal characteristics of a sample have been considered, the identity of the wood in question is still not apparent. In these instances—particularly in situations where a sample has been narrowed down to only a few possible remaining choices—it’s sometimes helpful to bring in specialized tests and other narrower means of identification.

The following techniques and recommendations don’t necessarily have a wide application in initially sorting out wood species and eliminating large swaths of wood species, but will most likely be of use only as a final step in special identification circumstances.

Odor

Believe it or not, freshly machined wood can have a very identifiable scent. When your eyes and hands can’t quite get a definitive answer, sometimes your nose can. Assuming there is no stain, finish, or preservative on or in the wood, quickly sand, saw, or otherwise machine a section of the wood in question, and take a whiff of the aroma.

Although new scents can be very difficult to express in words, many times the scent of an unknown wood may be similar to other known scents. For instance, rosewoods (Dalbergia spp.) are so named for their characteristic odor that is reminiscent of roses. Although difficult to directly communicate, with enough firsthand experience scents can become a memorable and powerful means of wood identification.

Fluorescence

While certain woods can appear basically identical to one another under normal lighting conditions, when exposed to certain wavelengths—such as those found in blacklights—the wood will absorb and emit light in a different (visible) wavelength. This phenomenon is known as fluorescence, and certain woods can be distinguished by the presence or absence of their fluorescent qualities. See the article Fluorescence: A Secret Weapon in Wood Identification for more information.

Chemical Testing

There are only a small number of chemical tests regularly used on wood, most of which are very specialized and were developed to help distinguish easily confused species with one another. They work by detecting differences in the composition of heartwood extractives. A chemical substance (called a reagent) is usually dissolved in water and applied to the wood surface: the surface is then observed for any type of chemical reaction (and accompanying color change) that may occur. Two of the most useful are the tests that are meant to separate Red and White Oak, and Red and Hard Maple.

Heartwood Extractives Leachability

Sometimes a wood species will have heartwood extractives that will be readily leachable in water and capable of conspicuously tinting a solution of water a specific color. For instance, the heartwood extractives contained in osage orange (Maclura pomifera) contain a yellowish-brown dye that is soluble in water. (This can sometimes be observed anecdotally when the wood is glued with a water-based adhesive: the glue’s squeeze-out is an unusually vibrant yellow.)

In a simple water extract color test, wood shavings are mixed with water in a vial, test tube, or other suitably small container, and the color of the water is observed after a few minutes. If the heartwood extractives are leachable by water, then a corresponding color change should quickly occur.

In addition to osage orange (Maclura pomifera), merbau (Intsia spp.), and rengas (Gluta spp. and Melanorrhoea spp.) are also noted for their readily leachable heartwood extractives. Because this property is quite uncommon, it can serve to quickly differentiate these woods from other lookalikes.

7. Look at the endgrain.

Perhaps no other technique for accurate identification of wood is as helpful and conclusive as the magnified examination of the endgrain. Frequently, it brings the identification process from a mostly intuitive, unscientific process into a predictable, repeatable, and reliable procedure.

Looking at the endgrain with a magnifier shouldn’t be a mystifying or esoteric art. In many cases, it’s nearly as simple as examining small newsprint under a magnifying glass. There are three components necessary to reap the full benefits contained in the endgrain:

I. A prepared surface.

When working with wood in most capacities, it becomes quickly apparent that endgrain surfaces are not nearly as cooperative or as easily worked as face grain surfaces. However, in this case, it is absolutely critical that a clear and refined endgrain surface is obtained.

For a quick glance of a softwood sample, a very sharp knife or razor blade can be used to take a fresh slice from the endgrain. However, in many denser species, especially in tropical hardwoods, one of the best ways to obtain a clear endgrain view is through diligent sanding. It’s usually best to begin with a relatively smooth saw cut (as from a fine-toothed miter saw blade) and proceed through the grits, starting at around 100, and working up to at least 220 or 320 grit, preferably higher for the cleanest view.

II. The right magnifier.

It need not be expensive, but whatever tool is used to view the endgrain should have adequate magnifying power. In most instances, 10x magnification is ideal, however, anything within the range of 8 to 15x magnification should be suitable for endgrain viewing. (Standard magnifying glasses are typically in the range of 2 to 4x magnification.)

These stronger magnifiers, sometimes called loupes, usually have a smaller viewing area than standard magnifying glasses. Fancier models—with built in lights, or larger viewing surfaces—are available at a premium; but the most basic models are usually only a few dollars.

III. A trained eye.

The third element that constitutes a proper endgrain examination is simply knowing what to look for. In analyzing the patterns, colors, shapes, and spacing of the various anatomical features, there is a veritable storehouse of information within the endgrain—all waiting to be unlocked. Yet, if these elements have not been pointed out and learned, the array of features will simply seem like an unintelligible jumble. The discipline of recognizing anatomical endgrain features is not easily summed up in a few sentences or even a few paragraphs, but it is nonetheless critical to the identification process. To this end, an in-depth look should be given to the various categories, divisions, and elements that constitute endgrain wood identification on the macroscopic level. (In this regard, macroscopic denotes what can be seen with a low-powered, 10x hand lens—without the aid of a microscope—rather than simply what can be seen with the naked eye.) Because the anatomy between softwoods and hardwoods is so divergent, each will be considered and examined separately:Still stumped?

If you have a mysterious piece of wood that you’d like identified, you’ve got a few options for next steps:USDA’s Forest Products Laboratory

You can mail your physical wood samples to the Center for Wood Anatomy Research.

Pros:

- Free

- Professional wood identification

Cons:

- Only available to US citizens

- Slow turnaround times (up to a month or more)

- Limited to three IDs per year

See their Wood ID Factsheet for more info.

Alden Identification Service

You can mail your physical wood samples (even small sections taken from antiques) to Alden Identification Service.

Pros:

- Professional wood identification

- Faster turnaround times (ranging from a few days to a week or two)

Cons:

- Paid service

See their ordering page for more info. (Note that Harry Alden has written several books while at USDA, including both Hardwoods and Softwoods of North America.)

Ask for help online

If the wood ID is merely a curiosity, or non-critical, you can post pictures of the wood in question.

Pros:

- Free

- No need to send physical samples

Cons:

- Greatly limited by the quality of the pictures provided

- Extra work usually required to get adequate clarity in photos

See article of Common US Hardwoods to help find the most commonly used woods.

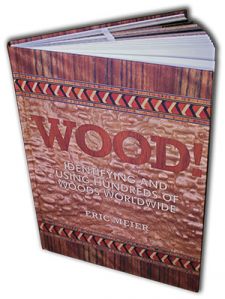

Get the hard copy

If you’re interested in getting all that makes The Wood Database unique distilled into a single, real-world resource, there’s the book that’s based on the website—the Amazon.com best-seller, WOOD! Identifying and Using Hundreds of Woods Worldwide. It contains many of the most popular articles found on this website, as well as hundreds of wood profiles—laid out with the same clarity and convenience of the website—packaged in a shop-friendly hardcover book.

If you’re interested in getting all that makes The Wood Database unique distilled into a single, real-world resource, there’s the book that’s based on the website—the Amazon.com best-seller, WOOD! Identifying and Using Hundreds of Woods Worldwide. It contains many of the most popular articles found on this website, as well as hundreds of wood profiles—laid out with the same clarity and convenience of the website—packaged in a shop-friendly hardcover book.

Why I will no longer be replying to every wood ID request I’ve replied to literally thousands of wood ID requests on this site over the past 13+ years, but as the site’s popularity has grown, so has the time demands for ID on a daily basis. (Contrary to what some may seem to think, I am not some all-knowing wood wizard that can instantly ID your wood. It can actually take me a long time to sift through a lot of different resources.) Over the past few years, my backlog of pending wood species to be added to the… Read more »

Are the following section images of more information? Unfortunately I couln’t get any better photographs.

Hello,

I am having a really hard time identifying wood. The object I have taken the sample from is quite brittle but I have tried my best to get as thin samples as possible on the microscope slides.

I know that it is a softwood and it’s origin in Austria. Could be a spruce, fir or pine? Can anyone make something of the image?

Many thanks in advance.

A.

Hi Ted,

I really enjoy this site. This is a custom made that I bought at an estate sale. I am unable to identify the wood. This is the view from the top. I am unsure if this is the natural color or a stain. Sorry about the glare. Any ideas?

Many thanks,

Deb

Ted, thanks for reply, here is another picture. Hope it is clear enough. Thank You

Wanda, Take a closer photo. Looks like maple from back here across the Mediterranean Sea. Look at Samuel’s photo above yours. Get that close. Jim, Black Walnut that we know and love is the center section of the tree or heartwood. The sapwood is whitish. Depending on how they cut the boards, and edge-joined them, you could have white lines out in the field of dark wood. If the wood is burned, you’ll have to plane or sand down the whole table to get past the burnt spot. I don’t know about staining it, you’ll might lose the white lines… Read more »

Hello,

Can you help me identify the type of wood used in this table? Many thanks.

The piece I’m working WON’T take stain….using a dark walnot….the wood has lines all through it white (light color)….dining room table and chairs…..has a 6 inch spot…burned smear….something spilled on it…..after I sanded the spot….NOW I can’t stain it or match it…ANY IDEAS out there…..very close grain with light lines on it dark wood….again it looks like walnut….Just can’t get rid of the spot (circle on table)….tried everything….Jim

Can anybody tell me what wood these chairs are, they have a sticker that says made in Italy??

Thanks Ted for your advice, you are probably right unfortunately, I did hope it was mahogany.

Samuel,

Eucalyptus (Lyptus in the furniture trade) looks a lot like mahogany, and is grown in sustainable resource farms to replace rainforest hardwoods like mahogany.

I can’t say for sure if that’s what your table is made out of, since there are about 137 varieties of Lyptus, Thank you for taking a closeup photo. There are a lot of exotic woods out there that I can’t identify.

I am trying to identify what type of wood this is before I try and sell the table. Can anybody help. I previously thought mahogany but I am now thinking it maybe a cope and cheaper material has been used. Thanks.

Ashleigh, I don’t know that there any appreciable difference in strength, 1/4 sawn wood just looks differently in some species than in others. Rather than looking at the “piping” system of the tree one way like Lina’s photo of Jan 10th, your boards are cut perpendicular (90 degrees, thus “quarter” of a circle – sawn) to the way her’s were, exposing the interesting lighter colored wavy bands as the “piping” system of the tree that carries water & nutrients are cut on their longitudinal axis. Oak lends itself to this kind of cutting, because it has large zylem & phloem… Read more »

Thank you so much for uour answers bill and ted! Amazed that people can identify wood from just a picture. Is being “quarter sawn” good for furniture? I have a few other pieces i will need to seek help with at a later date too :)

@ Brad S – I would guess Birch…

@ Ashleigh

February 9th, 2013 at 11:51 pm

Can anyone tell me what kind of wood this may be. It’s from an old dresser. I have tried matching it to pictures on the Internet but I just can’t. I know nothing about wood at all. I can upload a picture of more of it if needed. Thanks for your help!!

That is “quarter sawn” oak. Oak wood. :)

Ashleigh, quarter sawn oak. Rather than cut the boards out of a tree on so that the width of the board is perpendicular to the radius, your boards were cut with the width parallel to the radius of the log – like blades on a propeller, sticking out from the center of the tree, as one would look down on the log as a circle. Regular boards are cut like the sides of a box surrounding the circle of the center of the tree. Shannon, let me apologize in advance – If you want help with identification, you should take… Read more »

Can anyone tell me what kind of wood this may be. It’s from an old dresser. I have tried matching it to pictures on the Internet but I just can’t. I know nothing about wood at all. I can upload a picture of more of it if needed. Thanks for your help!!

And this please this is one of the legs it is very heavy

Hi guys need help please

Can u help me identify please

Scott,

It’s cedar.

Brad,

HAH…LOL.

This isn’t MY forum, I’m just a guest here like you, trying to share some knowledge with the masses. I do wish people would get in CLOSER to the wood with the photos, like macrophotography.

Hey, I’ve got it. All you submitters put a ladybug on your furniture, and take a photo so that the ladybug is as big as a pingpong ball. That will be close enough to make out what the wood is.

Thank you. I have been rebuilding guitars for a few years now, and honestly being driven quite crazy by the stains they put on. Just my taste. So glad i found your forum, thanks again.

Brad, It’s mahogany if the doors are fairly old, if they’re new, it could be eucalyptus, but most likely not. We Western Worlders are used to Mahogany and Cherry being a red color, because traditionally, that’s the STAIN that the woodworkers put on those woods to make them a uniform color. Mahogany right out of the tree runs from blonde as spruce, thru pinks, reds, and browns. Cherry can be blonde thru a medium brown that mellows darker as it’s exposed to light over the years. All the wood species have a particular “look” that furniture makers in the past… Read more »

I Have dismantled a couple of old bi-fold louvered closet doors, thinking they were mahogany. The grain was close, and so was the color, until they were sanded, now it is a blonde color. The stuff tools easy too, I wanted to use it for bracing on a mandolin, but I need to know what it is first. Any input would greatly appreciated. The top two are what I started with, the bottom are after cutting.

Hi there – following up on my sideboard, posted Jan 23. Walnut, not mahogany, from several opinions.

I was thrown by the colour, and by the ‘flame’ on the front of the piece – it didn’t look like burl walnut I’ve seen before.

But I love this website, and I’ll keep reading (and learning!)

Any idea on this ?

;-)~

I am trying to identify the wood used to manufacture the card table with Queen Anne style legs. Any suggestions?

Thanks

Hello,

I’ve been trying to figure out what kind of wood this is. Any ideas?

Hi, just purchased this sideboard – was told it was made around 1900s and is a family piece (his family originated in Nova Scotia). I think it’s mahogany .. can anyone confirm?

Which veneers are used here?

i can only recognize the rose leafs – maple.

Background-?

and the stem .. looks like somekind of walnut?

pls help i want to make this marquetry but i need to buy the certain veneers. if any other good combination pls tell :P

thanks!

I bought this pepper grinder from a man in a flea market who was a teacher doing the market for additional income during the summer months. It was toward the end of the day and he was talking really fast – he told me this is this special kind of wood used prior to 1910 and I totally didn’t recall the type. This pepper grinder works really well and it was a really great price. Can you identify?

Lina

January 10th, 2013 at 5:34 pm

Hi all, we’re trying to figure out if our kitchen cabinets are maple or oak… What do you think?

Thanks for all your input!

That is absolutely oak cabinetry. :)

And here is a picture of the tank itself

Here is a shot of the end grain.

We are trying to identify this wood from a water tank build by the Great Northern Railroad around 1900, I have been told it was made of clear redwood or cedar. I will add two more pictures to follow. Thanks in advance.

Hi, we are wanting to build a front door that gets lots of exposure to harsh Australian sun in an Australian hardwood. We are in a BAL fire area of 19 and we are wanting the door to be arched t the top. Its measurements are: 900mm x 2.4m and is 45mm thick. The house is going to be rendered in a lemon colour. Do you have any suggestions for an appropriate wood. If so, we’d love to know your thoughts. There’s a photo of the door attached.

Can someone help identify the wood from the back of this coffee table? My dad brought it back from Japan, WWll. The top is stained and varnished over and am wondering how far I should go in stripping it.Thank you!!

@Lina:

Looks like oak to me, maple has far less pattern.

And then self-answered to my own question: that sample is Cumaru. Wonderful wood, leaves nice surface!

Hard for to tell with this funny angle. Thoughts?

I have another piece that needs to be identified. Thanks again.

I would like someone to help me out on identifying this furniture. Thanks!

Hi all, we’re trying to figure out if our kitchen cabinets are maple or oak… What do you think?

Thanks for all your input!

Thank you for this great site! I couldn´t identify my wood though and I would like to know what this is…

Colour is quite right, it´s dense and have some pleasant odour when working with it. Picture shows a same 10cm long piece from two angles.

Thank you Ted. Where would all us wood noobs be without this data base.

SUGGESTION TO ALL PEOPLE SUBMITTING PHOTOS:

Include a CLOSE-UP of about a 4″ square area along with the photo from 5 feet back. A lot of the identification technique of wood species is being able to see the individual pores and structure of the wood and how close together the grain is. I would examine a piece of wood from about 6 inches away from my eyes if I was there with the wood. It’s kind of unfair to ask people to identify your wood from across the room.

Becki, Whether or not you waterproof them, covering would drastically reduce the graying effect of the Sun’s UV light. In Florida, you’d get mildew & mold if you covered them – you’ll have to use the trial & error method during your “rainy” season where you live. Olympic makes a good waterproofer that’s not as expen$ive as the over-advertised “name brand” water sealer. Heather, You have ‘bookended’ veneers on the top and doors – a nifty effect where the grains are mirror-images of each other. This is done by shearing the 1/16th (or less) veneer off of a board, rather… Read more »

@ Heather – Take a closer pic of the door frame and I’ll take another look.. the door insets are def oak…

@ Heather – the wood on top of the desk is definitely oak. The doors’ frames are something else though…

Ted,

Thank you SO VERY MUCH for your help. I will take care of them (I have two) exactly as you suggested. I have been reading online that outdoor woods should be covered when not in use. Once I put a waterproofer on them do I need to cover them as well? Living in SoCal it only rains about 2 months out of the year so we don’t have to worry about it too much.

~B

hi

what type of wood can i use with rodesein teak?

it must be more alike when its oiled

any help

thanks

Albie venter