DATA SOURCE(S): 2,3

Common Name(s): Black walnut, American walnut

Scientific Name: Juglans nigra

Distribution: Eastern United States

Tree Size: 100-120 ft (30-37 m) tall,

2-3 ft (.6-1 m) trunk diameter

Average Dried Weight: 38 lbs/ft3 (610 kg/m3)

Specific Gravity (Basic, 12% MC): 0.51, 0.61

Janka Hardness: 1,010 lbf (4,490 N)

Modulus of Rupture: 14,600 lbf/in2 (100.7 MPa)

Elastic Modulus: 1,680,000 lbf/in2 (11.59 GPa)

Crushing Strength: 7,580 lbf/in2 (52.3 MPa)

Shrinkage: Radial: 5.5%, Tangential: 7.8%,

Volumetric: 12.8%, T/R Ratio: 1.4

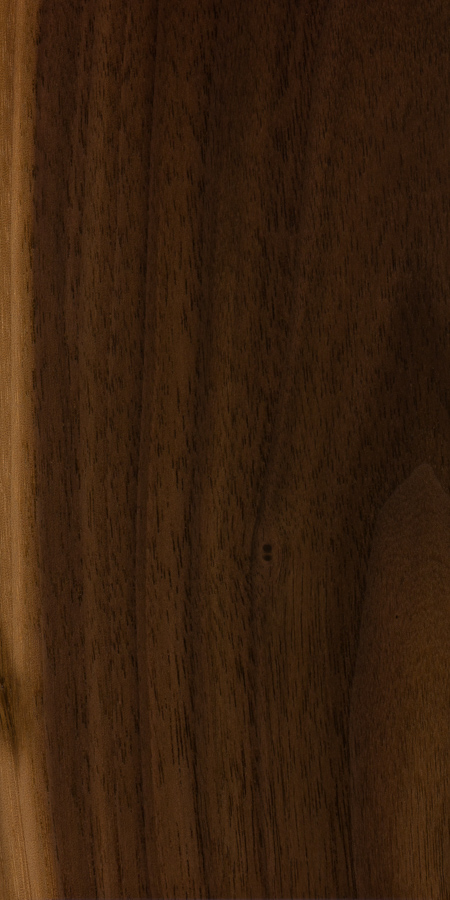

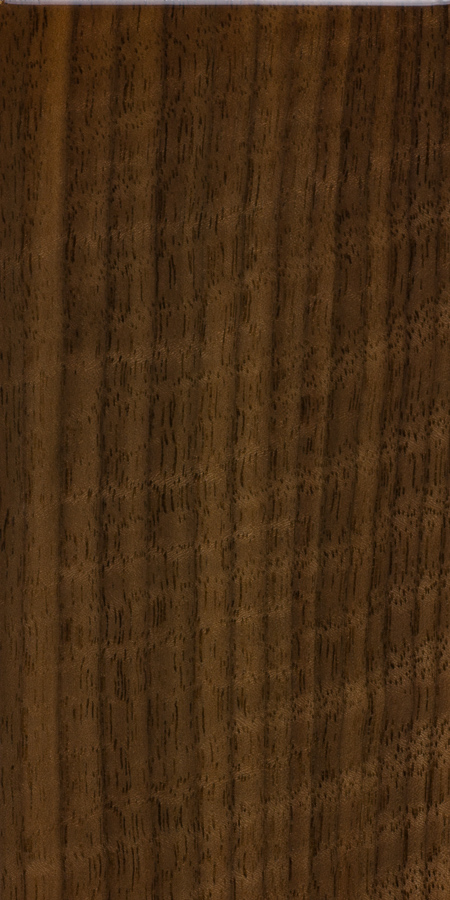

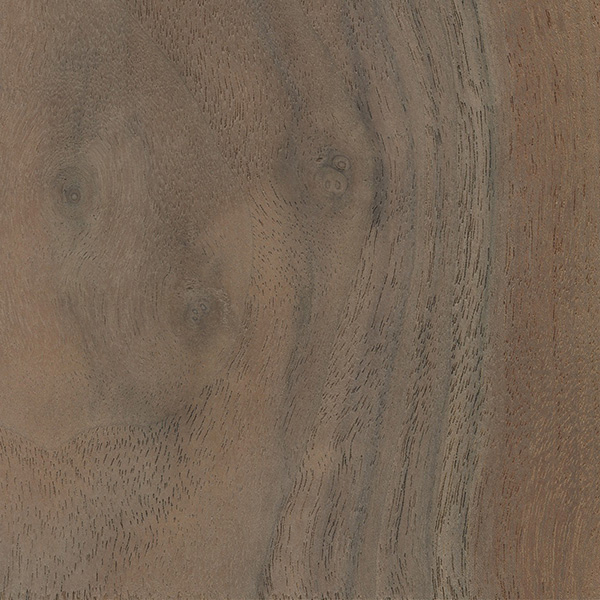

Color/Appearance: Heartwood can range from a lighter pale brown to a dark chocolate brown with darker brown streaks. Color can sometimes have a grey, purple, or reddish cast. Sapwood is pale yellow-gray to nearly white. Figured grain patterns such as curl, crotch, and burl are also seen.

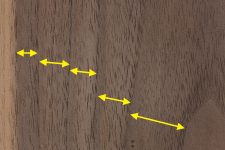

Grain/Texture: Grain is usually straight, but can be irregular. Has a medium texture and moderate natural luster.

Rot Resistance: Black walnut is rated as very durable in terms of decay resistance, though it is susceptible to insect attack.

Workability: Typically easy to work provided the grain is straight and regular. Planer tearout can sometimes be a problem when surfacing pieces with irregular or figured grain. Glues, stains, and finishes well (though walnut is rarely stained). Responds well to steam bending.

Odor: Black walnut has a faint, mild odor when being worked. This odor is common among most Juglans species (except butternut) and can be used to separate it from other unrelated walnut lookalikes.

Allergies/Toxicity: Although severe reactions are quite uncommon, black walnut has been reported as a sensitizer. Usually most common reactions simply include eye and skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Very popular and widely available, though board widths can sometimes be narrow. Wastage can be high if sapwood is not accounted for in projects. Considered a premium domestic hardwood, prices are in the high range for a domestic species.

Sustainability: This wood species is not listed in the CITES Appendices, and is reported by the IUCN as being a species of least concern.

Common Uses: Furniture, cabinetry, gunstocks, interior paneling, veneer, turned items, and other small wooden objects and novelties.

Comments: It would be hard to overstate black walnut’s popularity among woodworkers in the United States. Its good working characteristics, coupled with its rich brown coloration puts the wood in a class by itself among temperate-zone hardwoods. To cap it off, the wood also has good dimensional stability, shock resistance, and strength properties.

In limited situations, black walnut can sometimes be considered as an alternative to ebony and other dark colored hardwoods.

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Steve Earis for providing wood samples (crotch and burl), as well as Salem Barker (sculpture photo) and David Curran (birdseye walnut sample and image).

Full board scan

(35.4″ x 8.5″ / 90 cm x 22 cm)

Full board scan

(25.5″ x 6.0″ / 65 cm x 15 cm)

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: semi-ring-porous (sometimes closer to diffuse porous depending on growing conditions and age); growth rings generally discernible by gradual change in pore size from earlywood to latewood

Arrangement: solitary and radial multiples, sometimes forming a broken row in earlywood, with pore size grading down in latewood with overall diffuse distribution

Vessels: large to very large in earlywood, grading down to medium in latewood, few to very few; tyloses common

Parenchyma: diffuse-in-aggregates, banded (marginal), and sometimes reticulate (though most parenchyma tends to have very little contrast and can be quite hard to see even under magnification)

Rays: narrow to medium width, normal spacing; rays generally not visible without magnification

Lookalikes/Substitutes: The semi-ring-porous gradation in pore size from earlywood to latewood helps to separate black walnut from nearly all other unrelated imported walnut lookalikes, which tend to be diffuse porous—e.g., African walnut, New Guinea walnut, and Queensland walnut.

In mid-century and antique furniture, where the endgrain is not easily visible, black walnut is most commonly confused with Honduran mahogany. Although black walnut tends to be darker brown, both woods are variable in color and can have similar appearance when coloration is an intermediate golden brown. But on quartersawn sections, walnut will lack the ribbon patterning that’s usually seen in mahogany. And on flatsawn sections, the size of the pores can be closely examined for size gradation/variation (indicating walnut). Mahogany’s pores are of a much more uniform size, demonstrating its diffuse porous arrangement (which can be seen more clearly on the endgrain).

Notes: Within the Juglans genus, separation of individual species can be very difficult. Knowing the geographical source of the lumber is usually the best indicator, though the two most common commercial species, J. nigra and J. cinerea have an overlapping distribution in the eastern United States. While J. cinerea (butternut) tends to be lighter in both weight and color, the two can sometimes be confused if the color and weight are ambiguous. However, butternut trunks are are very often fluted, sometimes giving the growth rings in processed lumber a more faceted or polygonal appearance rather than perfectly curved.

Related Content:

I’m trying to sell this table that was gifted to me, but I don’t know what kind of wood it is and the endgrain is completely black.

I find figured walnut to be much more dense, sometimes to the point that the shavings are more like dust when turning. Tonal qualities for my use in custom game calls is wonderful!

The section titled workability states walnut is seldom stained. My experience is that it fades, especially in direct sunlight. I use a stain. I’ve been working with walnut for 45 years.

I’m planning to make a ballroom floor with mosaic parquet tiles of 4 different hardwoods. The looks of the woods should stand out enough from each other to keep an idea of a 4-color pattern. The tiles have many acute angles, and I’ll probably want to use a wax finish to keep it smooth and make it easy to glide and twirl without the wood splintering or wearing in the long run. I’d like to use the hardest possible common woods without spending a fortune. Initially I chose white oak, hard maple, cherry, and black walnut. Then I replaced cherry… Read more »

One nice thing about black walnut as it experiences the least amount of shrinking or deformity after being milled compared to our other domestic hardwood species.

I’ve read more than my fair share of on-line articles/info on whether black walnut is considered food-safe to be used for cutting boards, spoons, etc. Some say “yes” and others say “no”. So, what organization, governmental authority, etc. defines whether a given wood species is considered safe for such things?

I came across some birdseye walnut recently. Anyone familiar with it? Tried unsuccessfully to upload a pic. Can’t seem to find much about it.

is walnut wood proper for stairs ( treads )?

It’s absolutely hard (good nail and great screw adhesion) and stable enough, though let your stock acclimatize to your house before working it (set it near the stairway for a couple weeks and let ti adapt to the humidity in your home). Though if you’re carpeting it’s a lot like chroming your vehicle’s undercarriage. If you’re just after the tread substrate, there’s cheaper (and easier) solutions. If they’re to be visible treads (i.e. a spiral staircase, or an uncarpeted run), sure, knock yourself out. You can totally get walnut hardwood flooring, too. Avoid the sapwood if you can if you’re… Read more »

Can walnut wood be used for outdoor works? I want to use it to use for pool floors

Definitely not good for that. Walnut is very perishable. You’ll want something like teak, ipe, or white oak…

Don’t think that’s true. Has equivalent rot resistance as ipe.

Beautiful Timber with a lot of potential for wood working, furniture making & Marquetry. It is relatively soft timber, even though it is still classified as hardwood. This potentially gives it good work-ability, however it might not be the most durable option, if it is meant to be used as a flooring. I’m not saying that it is not suitable at all for flooring, we’ve completed number of project involving walnut flooring (planks or parquet). However in my opinion the hardness of the timber should be taken in to consideration, during the initial planning. Another disadvantage is the discolouration (as… Read more »

Making a dining room table found some nice black walnut, what is the best compatable hard wood for black walnut?

I made a dining table out of black walnut and white oak…. nice contrast and similar in qualities.

I have a black walnut grove and thoroughly enjoy tapping into my supply for the episodic use for (base protected/ off the ground) posts, indoor trim, and plank boards. This wood NEEDS to be treated in EVERY application. The rich color fades very fast outdoors without treatment, and slower but sure fading for indoor applications without treatment. Exterior water and insect damage occurs without treatment. I suggest using a one time application borate wood treatment (not the borax laundry detergent!) and cover with a clear wood oil sealant. Do not use raw linseed oil, since that promotes a green mildew… Read more »

It would be great if I could switch between woods easier so I could remember the number one-to-next (sorry I’m old and the numbers just don’t stick anymore).

I’m so glad I found this site I could just jump up and down. I have an antique /vintage shop in Tyler Texas and my main love is vintage old doors. Can’t beat them. As you wood workers I’m sure know. I’m so proud when I come across a old beautiful door, beat up, scratched doesn’t matter because I know the beauty it can be turned back into. There’s nothing on the market today that compares I don’t think,. Smart consumers are finally getting sick of being ripped off by the so-called big hardware chains that sell nothing made in… Read more »

There’s no test kit for woods that I am aware of. I’ve heard others speak of DNA testing for woods, but that is even more complicated and less accessible than traditional methods of wood ID. You still need a well-informed eye for wood ID (hence the site). https://www.wood-database.com/wood-articles/wood-identification-guide/

Hi ,

Would black walnut be ok for a bathroom countertop ? Lots of varnish required ?

Using any wood for a bathroom countertop will require a lot of protection because it will be presumably getting wet often. This is why tile is more common for countertops. That being said, walnut is extremely popular for furniture and countertops and overall very durable.

Walnut or any other wood is ok for a countertop but I’d recommend you to use a 2-part varnish, epoxy resin, or polyester resin as a top coat. However if you choose to go with wood, you’ll have to make sure you have designated places to sit hot items and finger nail polishes. Finally, over time you will need to rub out the top to get rid of the use marks and overall it will be more maintenance than granite or any type of stone.

um guys, the reason the wood is getting thinner and more expensive. Is um well, obviously most of the forests are chopped down! and monoculture isnt producing the amount that a hungry society consumes.

Loving the info BTW.

Whats special about Walnut hangers? Above post says it is susceptible to insects, presumably moths. So can’t hang woollen clothes on them? May be only for summer clothes(cotton/polyester).

Here in India we have only 3-4 months of winter, with lowest like 6degrees Celcius in the countryside. Towns are warmer, cities do not get winter!!

Sharpen your blades when cutting this species. Moderate blunting effect on hand and machine blades. Use both hands. This is very tough stuff. Pre Drill nail holes or prepare to bend a lot of nails.

Don’t know if this thread is even looked at these days but reading the comment above reminded me of somthing that Roy Underhill once said on “The Woodwright Shop”.

He was building a cabin in the woods and used black locust for the sills (which sat directly on the soil. He said he was using locust because it would last three years longer than granite.

Yes demo, this thread is still being read!!! What I am wondering though, did ANYONE READ THE SPECS OF THE WOOD???? I read people using this for outdoor projects or wanting too. READ THE SPECS….BLACK WALNUT IS PRETTY MUCH AN INSECT MAGNET!!!! Use it for it’s intended purposes….furniture, flooring, steps or stair rails. DO NOT USE FOR BUILDING DECKS, OUTDOOR WINDOW SILLS…ECT…unless you wish to have an insect farm!!!! Although my opinion is worthless, there’s my 2 cents worth!!! Good luck everyone and teach the young the CRAFT AND JOY OF WOODWORKING!!! Thank you Dad, 33 years later, I still… Read more »

I’ll second this. Indoor use, people.

…oh, AND teach your children woodworking.

Very good to point out. I have a few black walnut trees that surround my property. Every couple years I have to saw some down or trim branches to maintain property lines, electric wires, fences, etc… I’m always happy when it’s a walnut tree, because I keep that wood for art projects, and burn most of the other stuff. I even use the sap wood, because I just love working with it. Anyways, this last tree I took down was just a baby. Maybe 8 or less years old, but it was getting tangled in the fence. The thing was… Read more »

I’ve found that here in the southwest that Black walnut holds up extremely well to the direct intense sun, drying wind and the driving rain. Annual rainfall is 12″ per year. The joints stay tight and the surface pretty much unaffected even if not regularly cared for. Have built several doors with it and am extremely pleased with the results in stability and durability. I’m not sure I would use it for deck material as Michael is asking…But I sure would like to try some of the black locust for a door….

a whole bunch harder and more durable too.

Would black walnut be a good decking material? I’m trying to find a sustainable local alternative to IPE.

Just keep in mind it weighs a lot more wet than dry. This coupled with the price is why we don’t build boats with it.

Walnut has great weather resistance, but it’s spongy. Being spongy has a lot of positives and negatives. If you improperly seal it as a deck, it can cause sagging from the added weight, unless you account for the extra weight when you construct it.

Michael, if you read the Specs, Black Walnut is pretty much an INSECT MAGNET!!!

A great alternative would be Cedar….in my opinion if you’re not going to use Pressure Treated Pine.

It’s a NATURAL INSECT REPELLENT, has an incredible smell as well as color.

If you go with Cedar, just use a HIGH QUALITY SEALER and it should give you YEARS of enjoyment…..not to mention the tons of compliments you’ll receive.

Just found a barn built in 1800’s alot of walnut was used. Looking for an avenue to sell this stuff …any ideas?

What are the dimensions of the boards?

Greetings; This web site is really informative! I don’t do much with wood beyond taking a pine board and making a shelf now and then. But we live in a 105 year old ‘farm’ house out in the Ohio country-side, and we have solid hardwood floors on both floors, and we were told when we bought this place that the floors are black walnut. Judging from the information here, it looks like they likely are. The wood is finished, very dark rich brown with the grain indicated above, and I don’t know if it’s stained or not. Down it the… Read more »

As you can see my name is Richard. I just wanted to let all you wood workers out there know how disgusted I am over what the veneer industry has done with the veneer. I started to learn how to veneer in 1962 and have done it regularly ever since,I am now 74 years old and still working with it.I have gone through three 1500 sq.ft. flitchs of black walnut. My first flitch cost $.10 a sq. ft. Veneers were thick enough to do marquetry with. Today the stuff is so thin you can read the paper thru it and… Read more »

Richard, isnt that the way it is with everything? Prices keep going up and quantities keep going down. Just look in the grocery store. What you use to be able to buy for .50c is now $3.50 and you get 1/2 as much product. But hey, I hear the “Economy” is doing GREAT!!!

When I was growing up in the fifties and sixties my Dad used to talk about how you could get a 100 lb sack of potatoes when he was a kid for a quarter — that’s right, 25 cents, only no one had any money. Expensive stuff is better than having no chance to get it at all, in my book. While I agree its a shame what has happened to prices, who’s to blame for it?

The Federal Reserve. That’s who’s to blame.