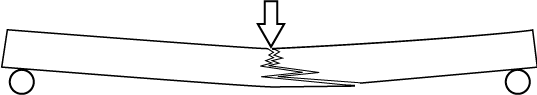

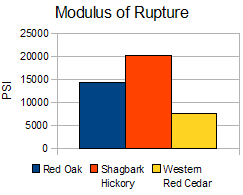

Modulus of Rupture, frequently abbreviated as MOR, (sometimes referred to as bending strength), is a measure of a specimen’s strength before rupture. It can be used to determine a wood species’ overall strength; unlike the modulus of elasticity, which measures the wood’s deflection, but not its ultimate strength. (That is to say, some species of wood will bow under stress, but not easily break.)

MOR is expressed in pounds-force per square inch (lbf/in2) or megapascals (MPa). This number is given for wood that has been dried to a 12% moisture content, unless otherwise noted.

In practical terms, the number itself isn’t all that meaningful, but it becomes useful to use in comparison with other woods. For instance, Hickory is known to have excellent strength properties among domestic species in the US, and has a MOR of 20,200 lbf/in2 (139.3 MPa). In comparison, Red Oak is another well-known wood used in cabinetry and furniture, and has a MOR of 14,300 lbf/in2 (98.6 MPa).

Get the hard copy

If you’re interested in getting all that makes The Wood Database unique distilled into a single, real-world resource, there’s the book that’s based on the website—the Amazon.com best-seller, WOOD! Identifying and Using Hundreds of Woods Worldwide. It contains many of the most popular articles found on this website, as well as hundreds of wood profiles—laid out with the same clarity and convenience of the website—packaged in a shop-friendly hardcover book.

If you’re interested in getting all that makes The Wood Database unique distilled into a single, real-world resource, there’s the book that’s based on the website—the Amazon.com best-seller, WOOD! Identifying and Using Hundreds of Woods Worldwide. It contains many of the most popular articles found on this website, as well as hundreds of wood profiles—laid out with the same clarity and convenience of the website—packaged in a shop-friendly hardcover book.

How are the mechanical data reported here? Specifically, are these stress values recorded with the criteria that 95% of the samples exceeded the reported stress value? Wood is highly variable, so how are the numbers here related to that variability?

The short answer is “it depends.” If you are only looking at North American woods, the data is much more robust, and I’d recommend looking at the USDA’s Wood Handbook for more info (it’s a free download from their website). Particularly the chapter on mechanical properties of wood. But in other instances, it’s more complicated. I recently stumbled on this statement from “South America Timbers.” “Information on South American timbers is scattered throughout a large number of technical publications written in different languages over a considerable period of time. Quite apart from the physical problem of gaining access to the… Read more »

is modulus of rupture the same as tensile strength?

It is similar. The difference is how they are measured. Tensile strength is measured in a direct tension test (pulling on either end of a bar), while MOR is measured in a bending test.

What is your opinion of using Impact Bending Strength as one measure of strength?

Perfectly valid way to measure strength. The only problem is that isn’t really universally adopted worldwide, so on this site dealing with woods from all over the world, there’d be massive gaps in data. This is why I have chosen to only include the “big three” that I discuss in this article: https://www.wood-database.com/worlds-strongest-woods/

Hi Eric! I have a doubt about how you can use the MOR. I am working on my final degree project, and I am analyzing the neck of a wooden guitar in Ansys Workbench. I want to determine if it breaks under the loads applied by the strings. My question is, can I use the MOR as the stress I cannot surpass in the wood? It would be like using the yield stress of steel in a metal piece. I am modelling the guitar as an element in longitudinal bending, with the grains parallel to the longitudinal direction, so I… Read more »

Initially, I don’t think MOR would be the best value to use, but I am not familiar with the type of breakage that you are referring to. The only time I’ve seen a guitar neck break is up near the tuning pegs at localized weak points, and not really along the main axis of the neck as it seems you are describing. (And this would probably be due to a sudden impact and not the slow loading in the MOR test.) Maybe I am not understanding the project well enough? Generally, I would think that MOE would be more of… Read more »

Hello! Thanks for your quick response. When you tighten the strings of the guitar, the guitar neck bends and a concentracion of stresses appears in the smallest section of it. I am doing my analysis there. You can see here an example of this tipe of analysis: https://www.slideshare.net/MattHayes5/fea-of-guitar-neck. My problem comes when I have to check if in that section a crack appears. That´s why I asked whether a crack should appear there if the stresses are higher than the MOR. And if the MOR is not convenient for that checking, my question was if I could use any other… Read more »

Hard to say for sure, but it seems like the force of the strings is also partially parallel to the wood grain as well as perpendicular. It’s probably not perfectly suited to any one calculation, but crushing strength would be a suitable measure of the wood’s strength when force is applied parallel to the grain.

If you are studying engineering, you should dig a little deeper and understand both the mechanical properties of wood, as well as the limitations and appropriate mathemetical modeling (in your case setting up FEM) To understand the meaning and limitations on the use of the “modulus of rupture” you need to read the USFPL “wood handbook.” In ship design we use the “proportional limit” for fully dry wood such as masts, and we use other values for wet wood, which was published by the the Bureau of Ships. For your use the USFPL should suffice. Go here to download the… Read more »

Eric, it still doesn’t make sense to me how MOE can be multiple times higher than a force that breaks the wood, MOR. According to the illustration of them both in your book, they look like they´re benchmarked exactly the same way. A wood blank supported on both sides and a force put perpendicular to the wood blank´s center. MOE bends it so you only measure the force to the point of where the wood bends, right? But how can then a force so strong bend the blank where a lower force which MOR tends to be break it? It… Read more »

The issue is that you are misunderstanding how MOE is measured. Your description of MOR sounds more or less correct, but MOE is different. It is simply a RATIO of two measurements, a weight (stress) applied to the wood, divided by the amount that the wood bends (strain). Being a ratio, MOE itself isn’t particularly useful or intuitive on its own, but is only of value when compared to other woods, or considered within its context.

which wood has highest moduls of rupture

Wood filter page is best tool for that: https://www.wood-database.com/wood-filter/?fwp_sort=mor

Eric – What is the difference between the modulus of rupture vs. the Fb bending force. I have a book that lists them both.

The MOR is the stress in the wood when it physically breaks. Fb, which is the allowable bending stress, is the nominal bending stress that is used in the design equations in accordance with the NDS. There is a very large factor of safety for wood due to the variable nature of wood

What are the factors of safety? More specifically for bending? How would I be able to determine the allowable bending if I was only given the MOR?

Divide by about 2 to get to the proportional limit (it varies by species in actual fact), and divide by roughly 4 for a working stress for dry clear straight grained unnotched specimens.

Better yet, look it up in an appropriate handbook!

https://www.fpl.fs.usda.gov/documnts/fplgtr/fpl_gtr190.pdf

What is the size of the sample and specifics of the fulcrum points (Distance, length, shape) Also, I’m guessing that the MOR number is the highest force reached and not the force being applied at the time of rupture, is this correct?

Eric-

First and foremost, thank you for compiling, formatting and sharing this data publicly. The data is incredibly useful.

Second, can you point me to some additional resources that explain how the MOR tests are done for wood? I am curious how specimens are selected, what grain direction is used, size of test pieces, sample size, etc.

Again, thank you for this wonderful resource.

Regards,

Ernie

I don’t know all of the particulars off the top of my head, and I don’t know if that information is publicly available. ASTM would be happy to sell you that info for about $70! https://www.astm.org/Standards/D143.htm

What is the specimen size used to determine MOR presented here. I’m assuming 20 x 20 x360 mm, can you verify?

Thank you!

for a school project i need to develop my own furniture but i have trouble with the MOR.

width length & depth should have impact on the amount of pascal it can withstand, but when i go to Wikipedia it says Pa = n/m^2 wich means that only depth and length have influence on the MOR

what should i do when i need to know how thick i need to make my table for more than 4 students to sit on

It’s a bit misleading to only look at the units of measurement for the strength rating. (The imperial units are even more straightforward, rated in pounds per SQUARE inch.) However, these tests are performed on a standard wood sample with no variation in size (including depth). So, in essence, what it’s saying is that given a certain sized sample of wood, when a force is applied to it directly in the center of the sample with and equivalent force of X newtons (or PSI), it will cause rupture. In practical terms, the easiest thing I can say would simply be… Read more »

does 0.075 makes sense for the MOR of LVL?

No, it does not. You need a unit of measurement with that number!

what is the modulus of rupture of orange tree?

so thats means the higher the MOR value, higher the wood strength. Is it sir? because I’m still confuse. Thanks for the reply.

Yes, higher MOR numbers mean stronger wood.

From a quick sort, it looks like the highest MOR is African Blackwood, with Bulletwood and Wamara coming in second and third.

sir, which wood has the highest modulus of rapture count and that too in Mpa?