Common Name(s): Wenge

Scientific Name: Millettia laurentii

Distribution: Central Africa

Tree Size: 60-90 ft (18-27 m) tall,

3-4 ft (1-1.2 m) trunk diameter

Average Dried Weight: 54.2 lbs/ft3 (870 kg/m3)

Specific Gravity (Basic, 12% MC): 0.72, 0.87

Janka Hardness: 1,930 lbf (8,600 N)

Modulus of Rupture: 21,990 lbf/in2 (151.7 MPa)

Elastic Modulus: 2,550,000 lbf/in2 (17.59 GPa)

Crushing Strength: 11,710 lbf/in2 (80.7 MPa)

Shrinkage: Radial: 4.8%, Tangential: 8.1%,

Volumetric: 12.9%, T/R Ratio: 1.7

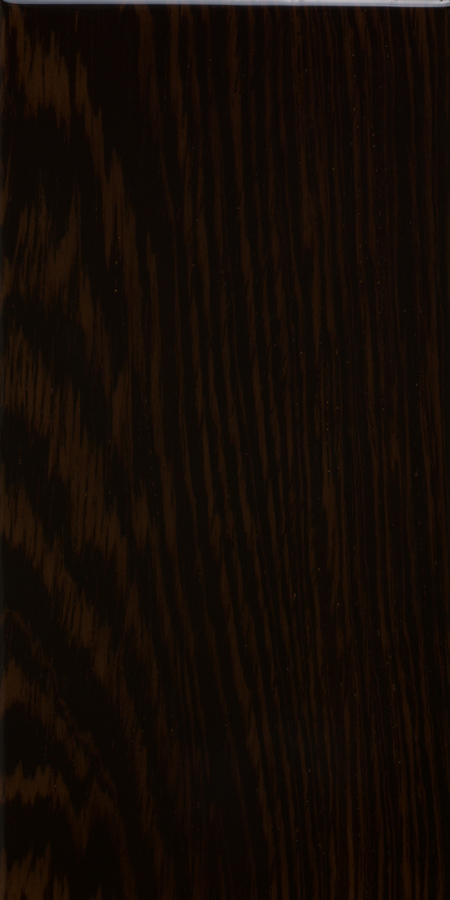

Color/Appearance: Heartwood is medium brown, sometimes with a reddish or yellowish hue, with nearly black streaks. Upon application of a wood finish (particularly an oil finish) the wood can become nearly black. However, unlike most other dark hardwoods, the heartwood of wenge can lighten (rather than darken) when exposed to sunlight.

Grain/Texture: Grain is straight, with a very coarse texture. Low natural luster.

Rot Resistance: Very durable; good termite resistance.

Workability: Can be difficult to work with hand and machine tools. Blunts tool edges. Sands unevenly due to differences in density between light and dark areas. Very splintery—care must be used when handling unfinished wood with bare hands as splinters can be very large and have an increased risk of infection. Very large pores can be difficult to fill if a perfectly smooth/level finish is desired.

Odor: Wenge has a faint, slightly bitter scent when being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, breathing wenge wood dust has been reported to cause central nervous system effects, abdominal cramps, irritation of the skin and eyes, and is also a sensitizer. Additionally, wenge splinters tend to take longer to heal and are more likely to go septic (get infected) than splinters from other woods. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Available in wide boards and veneer sheets. Prices are high, and are likely to remain so as supplies dwindle.

Sustainability: This wood species is not listed in the CITES Appendices, but is on the IUCN Red List. It is listed as endangered due to a population reduction of over 50% in the past three generations, caused by a decline in its natural range, and exploitation.

Common Uses: Veneer, paneling, furniture, turned objects, and musical instruments.

Comments: Usually pronounced WHEN-gii or WHEN-ghay, this incredibly popular African hardwood has excellent strength and hardness properties, though it’s much more frequently used for its rich dark brown color, which can be dark enough to be used as a substitute for ebony (Diospyros spp.) in certain situations.

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Steve Earis for providing the photo of the finished bowl of this wood species.

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous

Arrangement: solitary and radial multiples

Vessels: very large, very few; dark brown deposits common

Parenchyma: vasicentric, confluent, and banded (very wide)

Rays: narrow width; normal spacing

Lookalikes/Substitutes: The closely-related panga panga (Millettia stuhlmannii) is a nearly identical wood and is sometimes sold interchangeably as wenge. Technically, panga panga can be separated from wenge by testing a sample’s water extractives fluorescence (this test is outlined in the article on identifying Brazilian rosewood), where panga panga extractives will fluoresce a bluish-green, while wenge will not. Pheasantwood (Senna siamea) is another wood that can have a very similar appearance to wenge, though the grain tends to be a little finer, the parenchyma bands are a little narrower, and may lack the subtle bitter scent of the Millettia species.

Notes: Ripple marks present

Related Content:

Paring knife with Wenge scales. The second knife (handle) I’ve made and the first with proper tools. Buffed the handle so the softer wood is depressed relative to the darker, harder wood, effectively making the grain the grip. Highly recommend it.

Looks excellent! Nice work.

Has anyone here made an acoustic guitar body of Wenge? I bought a back and side set several years ago and am getting ready to use it for a crossover classical. It sounds like this wood could be risky to bend, and I don’t have a spare side piece. I’d appreciate hearing from someone who has done it. What worked for you – or didn’t work? I use an LMI side bending machine.

After bending the sides I’ll answer my own question. My quartersawn sides were tough and springy, with no tendency to crack or split. But getting them to “remember” the bent shape was surprisingly difficult. They were sanded down to 0.08″ and sprayed with Super Soft, but I still had to run them through two heat cycles, and after the second cycle I left each side in the bender overnight. That mostly tamed them, but I still had to touch up the waist on one piece with a hot pipe. This would be a good wood to make wooden springs from.

These are the spots.

I believe they are mineral deposits, and a probably harmless. I have only ever seen these yellowish deposits in the cloesly related panga panga, and you can even see these deposits pretty clearly in the endgrain 10x zoom image on my page of panga panga here: https://www.wood-database.com/panga-panga/

I think it gives the project a nice exotic look to it. What is the project itself?

I have a piece of wenge, which has yellow spots. Is this a sign of fungus in the tree? I scrapped a little and it seemed to be powdery. It didn’t change when applied alcohol.

Dear All . I have recently moved to a lovely large flat with Wenge doors and some panels , Unfortunately the sun has faded the wood and I now need to re stain . I have searched for a stain that matches but so far no luck . Can. anyone help with this please. Would be very grateful

best. Jon Kelly

Hi John,

I used no tint tongue oil about 27 years ago on inside wenge. It seems to be working well. I used about 8 coats sanding with ultra fine steel wool in-between.

Hi Everyone, I work for an outdoor art gallery specializing in hand-carved stone sculptures from Shona artists in Zimbabwe. The owner was gifted a set of salad bowls and utensils 10 years ago made of an unknown wood. After 6 months in our environment (Canada) the bowls became covered with a fine white ‘powder’ which I mistook for mold originally. Bathed them in vinegar, but a year later the white has returned, and she has asked me to clean them & seal them (oil has not worked to stop it). I now think it’s sap slowly but steadily squeezing out… Read more »

That wood does not look like wenge to me.

I’ve experienced a similar white powder residue appearing on a reddish hardwood sample I had, incidentally also from Africa. It was suggested to me that it was actually caused by the after effects of some sort of pressure-treating or thorough modification done to the wood.

Thanks Eric. I found some pictures I took before vinegar & after (with a clearer shot of the wood). I first went after a Kingwood idea; which brought me to African Blackwood, African Rosewood, Panga-Panga, and finally Wenge (Nobody I’ve shown this wood to can identify it).

Chances are it may just be something very obscure and only really used used locally. There are many decent woods that, for one reason or another, aren’t really seen on the international market, but are used locally.

It can be almost impossible to properly identify tropical hardwoods by looking at the finished products. There are simply too many species that look confusingly similar. You’d also have to question whether it’s the heartwood or the softer outer wood of any given species. Does it smell mildew-ish? I believe your pieces may be the softer outer wood and the white-ish stuff is actually sugar that has leached out and was subsequently attacked by mold, mildew, and/or yeast. Some of the tropical hardwoods do this, some stop after varying times and some never do stop turning white.

Handturned Wenge Ballpoint Pen and a Wenge & Huon Pine Ballpoint Pen.

Very hard on the tools, & needed a lot of coats of CA to fill the grain for a smooth finish.

Did manage to steam bend it as much as I needed for my project but it’s clearly not an easy wood to bend. Had to be quick!

Couple projects made from solid 8/4 thick Wenge. This stuff is really hard but does carve well. It is irritating and causes crazy splinters so be careful. It finishes nicely and darkens a lot. Smells terrible when cutting.

Does anybody have any experience of steam bending wenge? Thanks in advance.

It’s a very brittle wood so it might not be the best candidate for that.

Wenge kitchen. Love it!

First of all very interesting information.

I’m making a sauna and have here wenge. Is it possible to use it for sauna seats?

In a wet environment where one is likely to sit on it without clothing or wearing very little, I would not use wenge. I have been a wood worker for 35 years and use wenge a good deal in my furniture. I would not use wenge. One splinter on your thigh or rear end is all you ever need to understand why.

Agreed. This would be the least likely wood is want to sit on.

I have found that Wenge carves pretty well with a rotary carver. The grain holds together better than you would expect given the distinct light and dark layers. It takes a really nice polish and is very ding resistant. It has a pretty acrid small that can cause some nose irritation.

@Kevin Kempton

This is a lovely piece of work. It’s very stunning and eye-grabbing. Thanks for sharing with us.

~~~~

On point with discussion – This photo is one example of many that clearly shows that Wenge is not a “black wood”; like Dalbergia’s African Blackwood or Gaboon Ebony is. Why on this website and other sources is it listed as one? To me, it looks more like a nice sunset chocolate brown. It even has a somewhat discernable slate-purple hue to it.

because, 1. from a distance, wenge presents an almost black appearance, and 2. when oil finishes are applied to flat-sawn surface, it DOES go “jet-black”, though it may lighten again, depending upon exposure…

may be related to the fact that Millettia laurentii is a commercial substitute of Chinese Rose Wood (Dalbergia,Pterocarpus), so this name has been used,especially in the furniture field.

I made my through-neck electric bass with Wenge. Figured maple for body and mahogany for fretboard. Looks great, wenge was definitely a challenge to work with. super hard and tortures tools.

We get like other exotic wood are toxic to some degree. If your bowl is meerschaum your ok. It should look great as the meerschaum starts to take on a patina

My daughter made this beauty for me! Love the wenge, and all the other beautiful wood.

Turned wenge bowl, finished with laqueur

Has anyone ever used this for decking? I’m in Seattle so we often have light rain. I found a great deal ($6/bf!) on some wenge at a building material recycling company.

Nooooo! Not sure if you are serious, but did you read the description above? Very splintery (note “septic” . Beautiful wood, but a deck would be just about the worst application for this.

It’s also on an endangered list so use sparingly… not trying to be a tree hugger but common sense is dint use for decks or large builds,.. I am interested tho if you still have this wood available to you… I’ve never worked with it and actually cut my left hand off about 6 months ago… put most back on but taking it slow and doing small projects like cutting boards.. used to live in the Seattle area-ish and still have family there so please let me know if so! Here’s my latest cutting board

G’DAY folks, ihave been using wenge for making 3/4 pool cues 26mm x 9.5mm x 1100mm, this is very challenging, i am turning it on a cnc machine with a home built lathe sitting on the bed. nearly getting to about a 70% success rate with them turning straight and staying straight , the sealing bit is just as challenging, what i have tried so far is wiping epoxy paste onto the shaft using a blade to force it into the pores, no good, wax ,no good, oil, no good, soaked in 2 pack timber preserver overnight, no good, sprayed… Read more »

You might try medium viscosity CA glue to seal the pores. I know a lot of pen turners (myself included) have used CA glue both as a pore filler and a finish. A google search should turn up some ideas.

Hi Scott,

I would soak it in mineral spirits for an hour or so. The reason you’re having such trouble is that the oils in Wenge are what’s stopping your wood treatments. The mineral spirits or denatured alcohol will break those oils down and give you what you want.

One other sort of fun thing is that if you soak it in bleach overnight you get a really cool grain demarcation, looks sort of like Zebra wood but much much nicer, the effect is one of great contrast which would be very cool in a pool cue.

Jeff

To what Jeff said, this is true, I have used acetone myself. Try using a penetrating epoxy Seal afterward to stabilize .also urethane will form a good chemical bond to epoxy if applied within a certain time frame, check epoxy specks. Bob.

I use Wenge edge grain for cutting boards, and face grain for coasters. A pain to work with (splintering, uneven sanding sometimes etc), but I’ve had no problem with finishing. I use Osmo Top Oil (A German product that I buy from Windsor Plywood in Canada) and have great success. It is very thirsty, and a thin layer will soak in to the point I barely need to wipe off any excess. I then put two more coats on. I don’t have any feedback to use for long term results though yet.

Honestly the best way to achieve what your looking to do is to buy a vacuum pump and build a contour that’s air tight the size you need for your cues… then add the epoxy put the cue in container and start pump… this will draw the sit out of the wood and intern replace the air in the wood with epoxy.. they call this impregnated resin wood… you can purchase this wood but not sure about wrangle… good luck please let me know if you try

One of my favorites to work with. I only make tables and wenge has been a great wood to use.

Hi, Erin

Read your comment regarding the making of tables using Wenge.

What country are you in?

Regards.

Hi there,

I am making a small cabinet using wenge and considering giving it a textured finish with a gouge. I have no experience of carving or using gouges but i am willing to give it a go…! Please could anyone offer me some advice on wether this is possible (or not!), i have read a few posts above regarding free hand carving and turning.

Your help would be greatly received!

Cheers,

Matthew

il est difficile de donner un poli parfait ,surtout pour une sculpture de petite dimention , quant à la sculpture “à main levée” je n’ai jamais pratiqué mais il faut des gouges parfaitement affutées et attention aux échardes et à la poussière qui est très allergisante.pour ma part j’ai réalisé des sculptures de grande dimensions pour lesquelles la finition était en rapport avec la dimension .

I am a wildlife wood carver specializing in exotic hardwoods. Wenge is one of my favorite hardwoods to use. It is hard but very workable, with both hand tools and power tools. You can see several carvings created from Wenge on my website. LMwildlifecarving.com Good luck!

Nice wood carvings, I especially like the single Ram but all of your stuff is really nice. Here’s a link to a guy on youtube that also makes really cool stuff like yours. In this case it’s a cane with a mouse and a rattlesnake that are both carved but hyper realistic.

https://www.youtube.com/watch?v=UqYjTWjK5G0

Hey Mathew, no advice on carving but I’d just like to say, and i would say this to all who work with endangered species, that whatever it is you’re making with wenge, please make it as beautiful and lasting as humanly possible. You really want that piece to last and be appreciated for all time. Its rarer than gold. Treat it well.?

I am making a relief carving of a wolf in a forest on a 2″x14″x2′ piece. It it now my favorite wood. But one carving takes about six-eight months. And lots of bits. No wonder I cannot find examples of such carvings anywhere.

I’m using Wenge for kitchen worktops, what is the best oil treatment to apply?

Majority of the suppliers in UK used Danish Oil to finish kitchen worktops. It gives smooth finish, restore (darkens) the colour and it is food safe. I suppose you can use mineral oil too.

Hey hey

First of all very interesting information.

I’m making a sauna and have here wenge. Is it possible to use it for sauna seats?

Definitely not! The wood you are using for sauna seats should have low heat conductivity and therefore less dense woodtypes are typically used. In Finland (where the sauna is coming from) seats are nowadays built typically from heat treated aspen, obeche (abachi), alder etc. The point here is that these wood types heat up in the sauna but when you sit on them they do not burn. I’ll bet sauna seats made of wenge would burn your ass. In addition, if you are a frequent sauna user the seats are in heavy use and therefore I would use something cheaper… Read more »

Wonderful story Pekka!

if you want to use wenge as a hammer handle … sand with 400 – 600 – 800 – 1200 grit …then make epoxy with 10% dilution and in vacuum so max penetration is obtained … then sand again to prevent splinters in future …

I use Voss Chemicals G4 for it an super strong varnish ..

CAN WENGE BE USED IN CUTTING BOARD

I was going to do this recently based upon seeing boards for sale, but was advised not to due to it having very open pores that can trap bacteria. There is also the question of toxicity since the dust can cause reactions and splinters are particularly painful and prone to infection, but proper finishing should stop that. If you do use it in a cutting board, don’t use it as end grain as this would expose the pores directly to food contact and increase the amount of bacterial infiltration

Yes

Any wood known to blunt tools quickly would not make good cutting boards. At least not if you are using quality knives you don’t want to mistreat. Wenge tends to be mineral rich and using it as a cutting board would be like cutting against sand paper.

Hey I’m trying to make a tabletop of 22″x30″ how should I proceed to laminate 10 planks of 2″ 1/2 x 32

I’ve heard I need to clean the edged with acétone and uses titebond 3 glue.

Hi!

Is there someone that are able to tell if this is Wenge or Pangapanga (or something else?)? This is varnished…

Its difficult to say but generally Wenge is darker than that when sealed so its more likely panga panga

Please use wenge, or any other endangered species sparingly and beautifully so it lasts through the ages. As it stands, it’s a finite resource.

I’ve noticed a variety of species note they are difficult to machine and dull cutters, but Wenge has given me the most problems so far. I dimensioned a 3X24X1 board to make a 3/8″ thick small box for a paid of dividers. Sawing it felt like the teeth would rather slide instead of digging in, and my plane irons required sharpening at least several times If this wood is going to be worked by hand, the workability and harpoon like spiinters should definitely be taken into account when planning a project.

How about wenge or panga panga for outside stems on a strip canoe? The curved stems typically consist of three laminated layers starting at 1/4″ x 7/8″ each. Finished product is ‘glassed. Will these exotics steam and bend?

I just put a block onto my CNC machine (Taig CR2019 converted to Arduino driven CNC) and milling machine (Grizzly G704) to cut a wedding ring box for my upcoming wedding and I am happy to report that wenge machines beautifully! Once I got everything set up proper, I was getting beautiful and consistent sized chips. It’s definitely my favorite wood so far to machine. Since I couldn’t find any feeds or speeds or general milling tips, I had to do some guess work and nearly ruined my first block. So to spread some knowledge, here’s what I found: I… Read more »

Thinking of using this as a single tread (more like a ‘kneeler’) in my bathroom at the tub. Can this be sanded and sealed well enough to protect barefoot children from the dreaded splinters?

I think this could be done; you’d just have to be sure to sand it thoroughly and perhaps round over and sharp edges. But perhaps most importantly, use several coats of a film building finish like lacquer or polyurethane rather than a wax or oil finish.

Talk about splinters.. it sure will hurt someone if the fretboard edges isn’t rolled properly and buff to smooth. Tho 1 thing i like about this wood is the texture, color and durability compared to some fretboards. I include the picture of the neck we are currently doing 5 piece canadian maple with wenge stripes plus a wenge headstock plate. I told my guys to use carbon fiber rods on all necks for more stability, not that i do not trust maple/wenge combo, a 5 piece neck alone is good enough.. plus an extra muscle by putting a wenge fretboard… Read more »

Getting wenge splinters feels like getting shot. Do what ever you have to do to not experience a wenge splinter.

The one silver lining to Wenge splinters is that the wood is so tough that more often than not a splinter will stab me but not break off and lodge into my finger. The stabbing stings like a mother, but at least I don’t have to go digging for it with a needle like I do with other woods.

This is a beautiful, heavy, sturdy, very dark wood with striking streaks that are nearly black. Interestingly, I’ve noticed that it can tend to have some sort of white granular deposit in its open grain after sawing or planing. Which reminds me, I meant to look that up but never did. I had none of the allergic or irritant problems mentioned, but the splinters are very long, very sharp, very jagged, very painful, and very real. These are the kind that go in one place and come out another! I quickly learned not to run my fingers along the edges… Read more »

My hands hurt just reading your description of the splinters. I too am among the vicious-Wenge-splinter club. If anyone is planning on handling large amounts of unfinished Wenge boards or lumber that have square 90 degree edges, I’d recommend wearing gloves!

I find it to be a rather nasty wood to work with where the redeeming qualities of wenge do not overcome its characteristics.

Is Wenge and Ebony the same thing? If I order Wenge from a supplier will I get what I know to be Ebony?

Definitely not the same wood. They are both very dark colored, but different woods.

This makes a good handmade slingshot.

Would it be possible to make a butcher block desk out of katalox and wenge wood ?

is it possible to use this wood as a building material for a house?

This is an exotic hardwood from Africa which is considered endangered and is usually very expensive. Most applications are small pieces. With that said, I just finished making a small counter top using this wood and it is gorgeous.

What did you finish it with? I have a piece that we are adding to a counter top.

Yes, you will need to fingerjoint to your desired length. Tite bond 2 dark only. Hope you love your new wenge home. Please post pictures.

Nothing better, in my opinion, than a wenge neck. Strong, beautiful, it sounds incredible and feels amazing!

I use Wenge often in guitars I build often in the neck laminate or in the fret board. I find it to be easy enough to work with as long as you are aware that it will splinter on the edges and you can crack it if you try to bend it too much.

This is a bass I built where the neck and body are carved out of a single piece of Bubinga. I then glued a Wenge fret board to the neck.

I was looking at a few pieces of wenge & noticed how straight the grain is. Was wondering since I have been having trouble finding hickory in my area if making a hammer handle from wenge would be a good idea. Any thoughts? (Hammer would be for construction work so very hard on the hammer so any thoughts would be appreciated, if I should just save my money and search harder for some hickory :P

It would be nice looking but watch out with the splinters !!!

I am currently looking at an electric bass that has a neck of this material with a rosewood fretboard. Never seen anything like this and wondered how hardy it would be having strings putting stress on the wood?

Wenge should be plenty strong for this.

I think so, if you’re exceptionally wealthy and at the same time foolish with your money. Beyond that us mere mortals will never be able to afford to build a house with it. Imagine wenge hard wood floors but at the same time imagine the excruciating pain of sliding along that floor and picking up a splinter in your foot. I got a large wenge splinter and it was so painful I couldn’t see, I had to use a razor to cut it out because I couldn’t see it and had to cut it out by feel. That’s what you… Read more »

why would wenge have a blond center similar to sap wood

The white color will disappear as the air gets to it. It’s common when the wood is cut from the log to see white color which fades with time.

Found that cracks easy if not careful when giving pressure from point to point on lathe