Common Name(s): White oak, American white oak

Scientific Name: Quercus alba

Distribution: Eastern United States

Tree Size: 65–85 ft (20–25 m) tall,

3–4 ft (1–1.2 m) trunk diameter

Average Dried Weight:AVERAGE DRIED WEIGHT

Density is the measurement of a wood’s weight per unit volume. Here, "dried weight" specifically refers to wood at 12% moisture content, and values are given in pounds per cubic foot and kilograms per cubic meter. Also keep in mind that density commonly varies by +/- 10% from the average.

Click on the link "Average Dried Weight" for more details. 47.0 lbs/ft3 (755 kg/m3) Medium WEIGHT TIERS

Extremely Low: 0+ kg/m3

Very Low: 420+ kg/m3

Low: 520+ kg/m3

Medium-Low: 620+ kg/m3

Medium: 730+ kg/m3

Medium-High: 840+ kg/m3

High: 960+ kg/m3

Very High: 1,080+ kg/m3

Extremely High: 1,200+ kg/m3

Tiers are based on CSIRO provisional strength groupings (SD1-SD8) based on density.

Janka Hardness:JANKA HARDNESS

This test measures a wood’s resistance to indentation, and is the pounds of force (or Newtons) required to embed a .444" (11.28 mm) diameter steel ball halfway into the wood. Values are for side grain, measured at 12% MC.

Click on the link "Janka Hardness" for more details. 1,350 lbf (5,990 N) Medium-Low JANKA HARDNESS TIERS

Extremely Low: 0+ N

Very Low: 2,050+ N

Low: 3,150+ N

Medium-Low: 4,480+ N

Medium: 6,280+ N

Medium-High: 8,380+ N

High: 11,080+ N

Very High: 14,000+ N

Extremely High: 17,450+ N

Tiers are derived from CSIRO provisional strength classifications (SD1-SD8) in conjunction with the USDA's estimated hardness based on density.

Modulus of Rupture:MODULUS OF RUPTURE

Sometimes called bending strength, this test measures a wood’s strength before breaking (i.e., rupturing). Values are given in pounds of force per square inch and megapascals, measured at 12% MC.

Click on the link "Modulus of Rupture" for more details. 14,830 lbf/in2 (102.3 MPa) Medium-High MOR TIERS

Extremely Low: 0+ MPa

Very Low: 45+ MPa

Low: 55+ MPa

Medium-Low: 65+ MPa

Medium: 78+ MPa

Medium-High: 94+ MPa

High: 110+ MPa

Very High: 130+ MPa

Extremely High: 150+ MPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Elastic Modulus:MODULUS OF ELASTICITY

This test measures the wood’s level of deformation when under a given load. Higher values indicate less deformation (i.e., stiffer). Values are given in pounds of force per square inch and gigapascals, measured at 12% MC.

Click on the link "Elastic Modulus" for more details. 1,762,000 lbf/in2 (12.15 GPa) Medium-Low MOE TIERS

Extremely Low: 0+ GPa

Very Low: 7.9+ GPa

Low: 9.1+ GPa

Medium-Low: 10.5+ GPa

Medium: 12.5+ GPa

Medium-High: 14.0+ GPa

High: 16.0+ GPa

Very High: 18.5+ GPa

Extremely High: 21.5+ GPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Crushing Strength:CRUSHING STRENGTH

Also called compression strength, this test measures the maximum stress sustained before failure. Force is applied parallel to the grain (producing stress akin to chair legs). Values are given in pounds of force per square inch and megapascals, measured at 12% MC.

Click on the link "Crushing Strength" for more details. 7,370 lbf/in2 (50.8 MPa) Medium CRUSHING STRENGTH TIERS

Extremely Low: 0+ MPa

Very Low: 30+ MPa

Low: 36+ MPa

Medium-Low: 41+ MPa

Medium: 47+ MPa

Medium-High: 54+ MPa

High: 61+ MPa

Very High: 70+ MPa

Extremely High: 80+ MPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Shrinkage:SHRINKAGE

These values represent the percentage change in radial and tangential faces of the wood—as well as the total (volumetric) shrinkage—as the moisture content goes from green (maximum) down to oven-dry (minimum), approximating the wood's stability with changes in humidity. T/R ratio helps to estimate the uniformity of the shrinkage across different wood faces.

Click on the link "Shrinkage" for more details. Radial: 5.6%, Tangential: 10.5% Very High SHRINKAGE TIERS

Very Low: 0%+

Low: 3.6%+

Medium: 5.1%+

High: 6.6%+

Very High: 8.1%+

Tiers are based on tangential shrinkage (green to oven-dry) from CSIRO shrinkage classifications (1-5).

Volumetric: 16.3%, T/R Ratio: 1.9

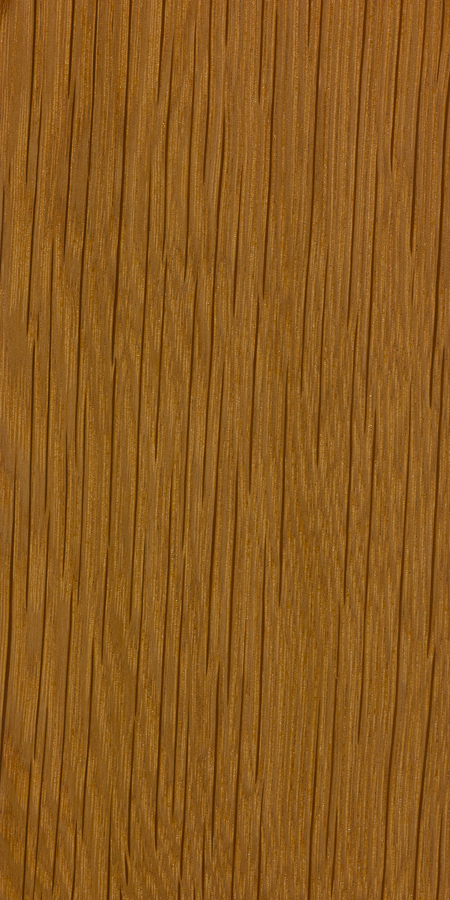

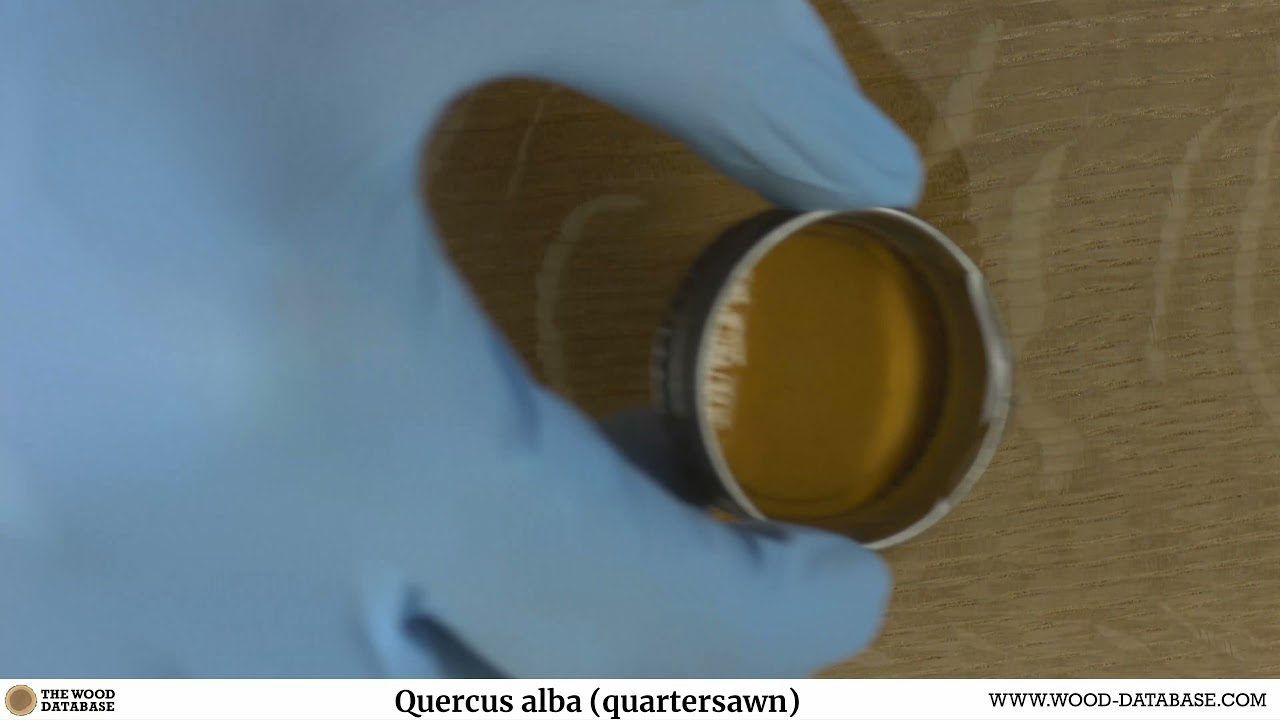

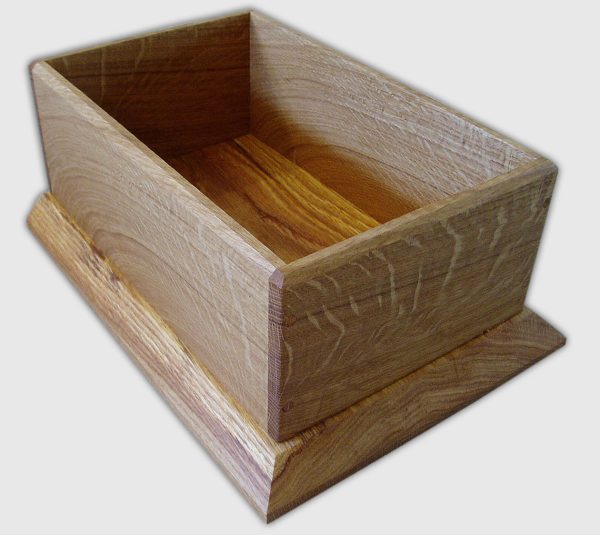

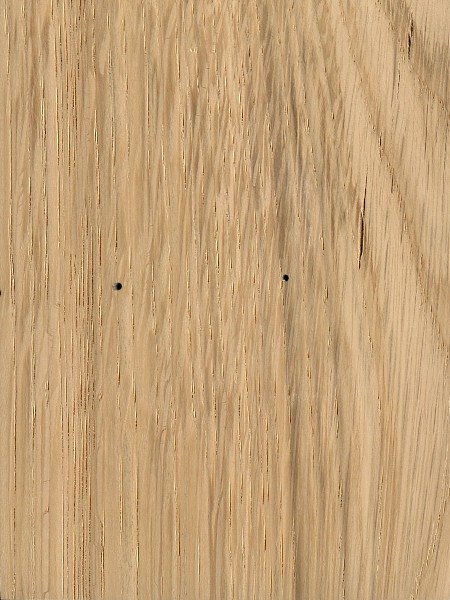

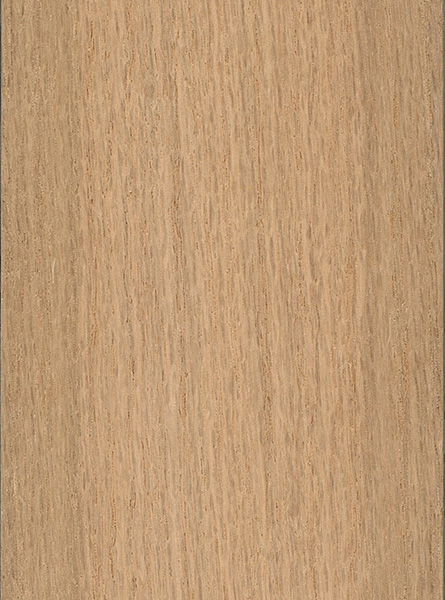

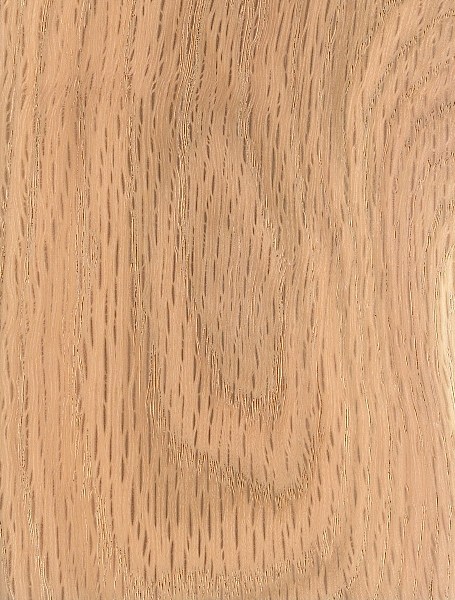

Color/Appearance: Heartwood is a light to medium brown, commonly with an olive cast. Paler sapwood is not always sharply demarcated from the heartwood. Quartersawn sections display prominent ray fleck patterns (see images below). Red oak (Quercus rubra) tends to have a slightly redder cast (as opposed to olive), but color alone isn’t always a reliable method of determining the type of oak.

Grain/Texture: Grain is straight, with a coarse, uneven texture.

Rot Resistance: Rated as very durable; frequently used in boatbuilding and tight cooperage applications.

Workability: Produces good results with hand and machine tools, though it has fairly high shrinkage values, resulting in mediocre dimensional stability, especially in flat sawn boards. Along with the related red oak (Quercus rubra), white oak scored near the very top in an assessment of the machinability of domestic hardwoods. The wood can react with iron (particularly when wet) and cause staining and discoloration. Responds well to steam-bending. Glues, stains, and finishes well.

Odor: Has a distinct smell while being worked that is common to most oaks. Most find it appealing.

Allergies/Toxicity: Although severe reactions are quite uncommon, oak has been reported as a sensitizer. Usually most common reactions simply include eye and skin irritation, as well as asthma-like symptoms. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Abundant availability in a good range of widths and thicknesses, both as flatsawn and quartersawn lumber. Usually slightly more expensive than red oak, prices are moderate for a domestic hardwood, though thicker planks or quartersawn boards are more expensive.

Sustainability: This wood species is not listed in the CITES Appendices, and is reported by the IUCN as being a species of least concern.

Common Uses: Cabinetry, furniture, interior trim, flooring, boatbuilding, barrels, and veneer.

Comments: Strong, beautiful, rot-resistant, easy to work, and economical: white oak represents an exceptional value to woodworkers. It’s no wonder that the wood is so widely used in cabinet and furniture making.

In addition to the wood, white oak is also the state tree for three states (Connecticut, Illinois, and Maryland). Indeed, Connecticut’s state quarter (1999) was minted with a picture and inscription of a famous white oak, the Charter Oak. In 1687, a cavity within the tree was used as a hiding place for the Connecticut Charter of 1662 to prevent its confiscation by the British.[1]Corrigan, D. (2020, October 31). Hiding the Charter: Images of Joseph Wadsworth’s Legendary Action. Connecticut … Continue reading

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Steve Earis for providing the turned photo of this wood species.

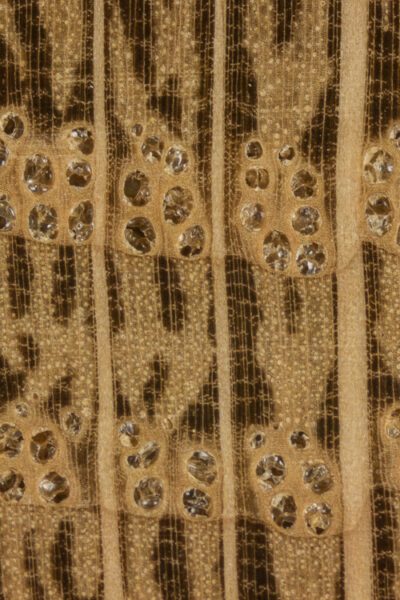

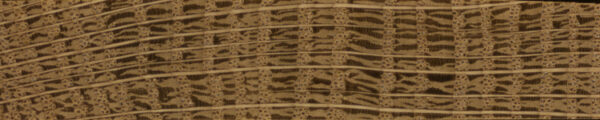

Identification: See the article on Hardwood Anatomy for definitions of end grain features.

ArrangementARRANGEMENT

Describes the more individual pore arrangements found throughout the end grain surface, such as solitary, multiples, chains, clusters, etc.

Click on the link “Arrangement” for more details.: exclusively solitary earlywood pores in two to four rows, latewood pores in radial/dendritic arrangement

VesselsVESSELS

Describes the relative size and frequency of the pores (vessels), as well as any contents found in the pores, such as tyloses, colored mineral deposits, etc.

Click on the link “Vessels” for more details.: very large in earlywood, small in latewood; tyloses abundant

RaysRAYS

Describes the relative width and frequency of the rays (appearing as thin vertical lines on the endgrain), as well as a note on if these rays are visible with/without magnification.

Click on the link “Rays” for more details.: rays of two distinct sizes: narrow and very wide, normal spacing; wider rays are conspicuous on end grain even without magnification.

Lookalikes/Substitutes: Besides being confused with red oak (see notes below), oak species in general are sometimes confused with other ring-porous hardwoods like chestnut (Castanea genus) and ash (Fraxinus genus). But oak species have very wide rays which make them easy to separate from most other ring-porous woods, which generally only have narrower rays.

Notes: White oak heartwood tends to have tyloses (small, bubble-like structures) that can be seen in the large earlywood pores, while species of red oak lack tyloses. Additionally, ray height, when viewed on the face grain, tends to be taller/longer on white oak (sometimes exceeding one inch in length). See the article on distinguishing red and white oak for more details.

Related Species:

Related Content:

References[+]

| ↑1 | Corrigan, D. (2020, October 31). Hiding the Charter: Images of Joseph Wadsworth’s Legendary Action. Connecticut History. https://connecticuthistory.org/hiding-the-charter-images-of-joseph-wadsworths-legendary-action/ |

|---|

hello. I am from Central America, precisely in Guatemala we have very large and hard oaks in the cloud forest mountains, I attach these two images of white and red oak. I would like to send you a sample so I can analyze these two species.

I am treating white oak with tung oil (Old Masters, which is thick and seems to be without additives). Most instructions advise to use 3-5 coats, but with white oak, the first coat looks still wet on the surface after a couple of hours. I also tried mixing with turpentine which seems to absorb a little more, and I spread it out with a dry brush after half hour where it dried more, but it seems like 2 coats is the most it can take, and there is quite a bit left to wipe off after the 2nd one. Anybody… Read more »

I bought white oak from two different sawmills, one in Philadelphia (probably sourced locally) and one 50 miles far in rural Pennsylvania. The former was air dried and stickered for at least 4 years, the latter kiln dried – so I was told. The two look quite different. They both look like oak to me, but the hue and smell are quite distinct. The one lighter in color is the kiln-dried one. Obviously one is quarter sawn and the other flat sawn, and I can’t see the characteristic white oak flecks in the flat sawn one. Also, the lighter one… Read more »

There’s a lot of variation in oak, especially color. Some species can loose a bit of their natural color when kiln dried (such as black walnut). The upside is that they are better protected/sterilized against pests.

Thanks. After planing a few pieces I realized that the lighter one mus be sapwood, because the other pieces are darker and closer to the other batch.

Can anyone say what the cream-colored marbling effect is called in the edge of this oak board? It’s about 3/8” deep into the wood. Oxidation? Fungus?

It looks like spalting to me, so basically decay fungi.

Thank you.

I’m trying to identify this wood. I’ve come into 7 ten foot boards that are 2” thick of this reclaimed wood. It is super dense and hard and wicks water easily, which sounds more like red oak with the porosity. That said, I think it looks more like white oak. Any suggestions? Here is edge grain, face grain, end grain, and an overall shot.

I am not sure what species that is, but from the side view of the board it does not look like white oak, which generally has noticeable ray flecks. It kind of looks like ash to me.

it looks a bit like english Oak to me

I am thinking about buying some unfinished oak planks from a local wholesaler. He gets them from pipe line companies that use them to haul pipe on railcars then give them to him after one use.

I suspect it is Live Oak since that is the most abundant oak in this area. I build furniture and cabinets in my home shop. I have a jointer to finish the edges.

Of course I will select the boards that are straight but Is there anything else I should consider or be cautious about?

Hi, is this queréis alba the best wood for barrels for aging rum or bourbon??

It’s there a place where I can bay already cut this wood for barrels.

Thanks.

It’s the ONLY wood for bourbon, by definition.

I must respectfully correct this. White Oak is the most commonly used for bourbon barrels, but the rules state bourbon must be aged in new, charred oak barrels. The type of oak is irrelevant. Also, be careful making your own spirits; if you don’t know what you’re doing, you can end up blind or dead.

Cheers. ?

But… who would use anything but white oak? Red oak, e.g., barrels would soak through in months.

Hi there, we recently bought a 1920 farmhouse in MD. The house itself needs to be completely renovated and updated. This is going to require multiple structural changes. There have been various pieces of the structural elements that have been confirmed to be white oak. Can someone tell me how strong a 5.5”x 5.5” beam would be? What find if load can white oak carry?

Lumber span tables are commonly available on the internet with a simple Google search. The span tables will give you all of the essential load data you need.

You will need a knowledgeable structural engineer to tell you the strength of your beam. The member can be grade in-situ to provide a better representation of strength. It also depends how the beam is installed and its connections.

I can help you with that or you can find another professional to help you out.

I’m refinishing a rocking chair( white oak) frame.is there another wood that will match up with a clear coat . need to replace some slats on seat.

Is there a reason why you just wouldn’t use more white oak? It’s fairly abundant and reasonably priced.

Hello. I’ve recently acquired this beautiful side board (dated approximately 1910-1915). I’m going to bring it back to life and I’m wondering what type of wood it is. Oak, Cherry? Also, what stain would you recommend for restaining the top and mirror area.

Thank you.

I am trying to find out what kind of wood my headboard is.. Any help would be appreciated.

Can’t tell from that picture, sorry!

From what I can tell from this picture it looks like walnut

I am thinking of using White Oak in lieu of Cypress for rebuilding my exterior porch railing. I know that White Oak can be stained, but can it be painted to a nice smooth finish?

Cypress has excellent rot resistance and will hold up much better in exterior conditions but to answer your question: Oak in general is not a very friendly wood to paint if you are looking for a smooth surface. The grains are very open and porous so you will still see the graining even after being painted. Hard Maple is a much better wood if you are looking for a smooth finish paint job and it is just as strong as White Oak. Make sure it is Hard Maple as there are soft maple woods as well. The other option if… Read more »

White oak is not difficult to paint to a smooth finish, so long as it is well sanded. It doesn’t absorb the paint nearly as much as red oak, as its grain is MUCH tighter. But, that said, I would suggest not painting high quality expensive hardwoods in general — you’re covering up half of what you are paying for. Softwoods actually tend to expand less than hardwoods due to moisture exchange, which is one of the reasons they are used often in exterior builds. Plus, they tend to be less expensive, and paint easily. You’ll likely pay $5.50+ per… Read more »

How stable would true American white oak be in instruments, such as guitar body’s? It seem to have a high shrinkage rate, but if it is quarter swan would or will that apply assuming that it has been properly dried?

Fantastic writing ! Apropos , if your business requires a IRS 4868 , my business partner filled out a sample version here https://goo.gl/jyjFyS.

I always found the same but i think is just because the grain sometimes has ondulations. If you peel the bark of a holm oak(quercus ilex) you will see it more clearly. Those parts seem to have bad grain but they never gave problems to me when doing steam bending of kayak ribs ;)

So…. Isn’t “Quercus Alba” actually the Japanese white oak?

This articles says its from the US. Is all white oak lumped into a

generalized category?

Quercus alba is definitely a Stars ‘n Stripes native. The term White Oak can be a more generalized term, but Quercus alba is very specific, and it’s native to eastern sections of North America.

Maybe the tree has been subsequently planted in Japan too?