|

Common Name(s): Black Oak, Eastern Black Oak

Scientific Name: Quercus velutina Distribution: Eastern North America Tree Size: 65-80 ft (20-25 m) tall, 3-5 ft (1-1.5 m) trunk diameter Average Dried Weight: 45 lbs/ft3 (715 kg/m3) Specific Gravity (Basic, 12% MC): .56, .71 Janka Hardness: 1,210 lbf (5,380 N) Modulus of Rupture: 14,430 lbf/in2 (99.5 MPa) Elastic Modulus: 1,736,000 lbf/in2 (11.97 GPa) Crushing Strength: 6,450 lbf/in2 (44.5 MPa) Shrinkage:Radial: 4.4%, Tangential: 11.1%, Volumetric: 15.1%, T/R Ratio: 2.5 |

Color/Appearance: Has a light to medium reddish-brown color, though there can be a fair amount of variation in color. Conversely, White Oak tends to be slightly more olive-colored, but is by no means a reliable method of determining the type of oak.

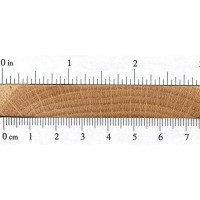

Grain/Texture: Has medium-to-large pores and a fairly coarse grain.

Endgrain: Ring-porous; 2-4 rows of large, exclusively solitary earlywood pores, numerous small latewood pores in radial arrangement; tyloses absent; growth rings distinct; rays large and visible without lens; apotracheal parenchyma diffuse-in-aggregates (short lines between rays).

Rot Resistance: Falls somewhere between slightly durable to non-durable. Red oaks such as Black Oak do not have the level of decay and rot resistance that White Oaks possess.

Workability: Easy to glue, and takes stain and finishes very well.

Odor: Has a tell-tale smell that is common to most oaks. Most find it appealing.

Allergies/Toxicity: Although severe reactions are quite uncommon, oak has been reported as a sensitizer. Usually most common reactions simply include eye and skin irritation, as well as asthma-like symptoms. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Slightly less expensive than White Oak, Red Oak is in good/sustainable supply and is moderately priced. Thicker 8/4 planks, or quartersawn boards are slightly more expensive per board foot.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species.

Common Uses: Cabinetry, furniture, interior trim, flooring, and veneer.

Comments: Not to be confused with Bog Oak (which is actually black in color), Black Oak falls into the red oak group, and shares many of the same traits as Red Oak (Quercus rubra). Red Oak, along with its brother White Oak, are commonly used domestic lumber species. Hard, strong, and moderately priced, Red Oak presents an exceptional value to woodworkers—which explains why it is so widely used in cabinet and furniture making.

- Bog Oak

- Brown Oak

- Bur Oak (Quercus macrocarpa)

- California Black Oak (Quercus kelloggii)

- Cherrybark Oak (Quercus pagoda)

- Chestnut Oak (Quercus prinus)

- English Oak (Quercus robur)

- Holm Oak (Quercus ilex)

- Japanese Oak (Quercus mongolica)

- Laurel Oak (Quercus laurifolia)

- Live Oak (Quercus virginiana)

- Oregon White Oak (Quercus garryana)

- Overcup Oak (Quercus lyrata)

- Pin Oak (Quercus palustris)

- Post Oak (Quercus stellata)

- Red Oak (Quercus rubra)

- Scarlet Oak (Quercus coccinea)

- Sessile Oak (Quercus petraea)

- Shumard Oak (Quercus shumardii)

- Southern Red Oak (Quercus falcata)

- Swamp Chestnut Oak (Quercus michauxii)

- Swamp White Oak (Quercus bicolor)

- Turkey Oak (Quercus cerris)

- Water Oak (Quercus nigra)

- White Oak (Quercus alba)

- Willow Oak (Quercus phellos)

|

|

|

|

Would someone please confirm if this is black oak as unlike your pictures it is actually black

I recently listed these candleholders as ‘solid oak’ on my website. now somebody commented that they’re not oak but maybe Brazilian Mahogany. Can you help to clarify please?

I would tend to agree at the very least that they are not oak. It looks like a diffuse porous hardwood. Would need to get a clear, well-lit, closeup shot of the endgrain to have a better chance at ID.

Hi Eric, many thanks for your reply which is very much appreciated. I took a few new photos and hope, that you might be able to tell me a bit more about the wood i used. It was part of a pallet by the way, and to me looked like oak.

Thanks in advance, Jorg

After seeing the endgrain, we can safely rule out oak. Where are you located, or where was the pallet from?

The pores appear to be in a diagonal or radial pattern, which reminds me of some species of Eucalyptus, but it could be a lot of other woods too.

Hi again Eric, thanks for replying. I live in the United Kingdom and the pallets we have are usually used for carrying sheet metal.

It looks alot like Hevea to me, Rubber wood.

Are these floorboard black oak? Endgrain seems to match. thanks

It looks like a species from the red oak grouping, which black oak is a part of. Whether it is specifically black oak is not something I can say for sure. It could be any number of species. https://www.wood-database.com/wood-articles/distinguishing-red-oak-from-white-oak/

Is this Black Oak? I found it in southern New York

Whatever it is, those are some nice looking pieces! I’d need a closer/clearer/sanded view of the endgrain to get a better idea of species; but there isn’t a way that I know of to tell various oak species apart beyond just white or red oak categories. Maybe the bark could give some clues, but I don’t know much about bark and mainly have knowledge of the wood itself. (It should also be noted that Black Oak, despite it’s name, is not really any darker or different than plain old red oak.)

I use quartersawn black oak a lot for ukulele sides,even have made entire ukuleles out of it.We had some friends that had a tree in their yard here in Washington that had to be cut down in 1990..bandsawed the tree with a neighbor.I made a set of shaker style kitchen cabinet doors for a vacation home also from the wood..works well,like red oak. Quartersawing the wood brings out ripples and flakes!It’s been dry for 20 years or more…wonderful to work with,soaks/steams/bends well in thin slices.The ukulele pictures..sides have only tru-oil gunstock finishing oil on them. Nice website!..I’m trying to figure… Read more »

We matched up our tree/wood type by the LEAVES that were on the living tree at the time it was fallen..which doesn’t help you,of course.It would be hard to tell red oak from black oak other than the finished grain seems more ripply and more flakes in the black oak.The black oak is a rare tree around here,only one that I have ever seen locally.More than likely if the species you have was used for a barn building,it was a species that was very common in your immediate vicinity. I’d take one of the “common”(boards that you have several of)… Read more »

I live in Missouri where we have a lot of hardwood… Most is oak but I have a hard times determining what type it is. I can look at the grain and match it, but it all old, I have lumber out of barns that is 80+ years old. The most of it nail free, used in a loft of a barn if you know what I mean. There are no nails, and better than 15″ wide and I see a lot of quarter sawed lumber…I also have some oak floor joist that are 20+ ft. long that came out… Read more »

I use quartersawn black oak a lot for ukulele sides,even have made entire ukuleles out of it.We had some friends that had a tree in their yard here in Washington that had to be cut down in 1990..bandsawed the tree with a neighbor.I made a set of shaker style kitchen cabinet doors for a vacation home also from the wood..works well,like red oak.Quartersawing the wood brings out ripples and flakes!It’s been dry for 20 years or more…wonderful to work with,soaks/steams/bends well in thin slices.The ukulele pictures..sides have only tru-oil gunstock finishing oil on them. Nice website!..I’m trying to figure out… Read more »