Workability: Despite its high density, brazilwood has good workability, though interlocked grain can result in tearout during surfacing operations. Turns, glues, and finishes well.

Allergies/Toxicity: Although severe reactions are quite uncommon, brazilwood has been reported to cause skin irritation, as well as a number of other effects, such as headache, nausea, swelling skin, and blisters. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Common Uses: Stringed instrument bows (violin, viola, cello, etc.), veneers, inlay, carvings, and turned objects.

Comments: Perhaps the only wood that was so famous, it was responsible for the naming of an entire nation. When Portuguese ships discovered the trees on the coast of South America in the sixteenth century, they found that the wood yielded a water-soluble red dye which made for a very valuable and lucrative trading commodity. They named the tree pau brasil (the term pau meaning wood, and brasil meaning red or ember-like). Such a vigorous trade resulted from this wood that early sailors and merchants referred to the land itself as Terra do Brasil, or ‘Land of Brazil,’ and the name stuck.

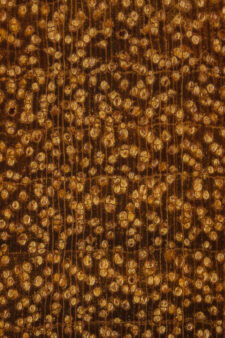

Brazilwood is also known as pernambuco to bow-makers. Although the density and mechanical data listed above is average for the species, bowyers tend to favor the heaviest and strongest pieces for use in bows. One study evaluating the suitability of pernambuco staves for bow manufacture found that the highest grades [classes] of the wood had “a lower frequency of vessels and rays and a higher percentage of fibers when compared to the other classes. They also had higher values of density, speed of sound propagation, modulus of elasticity and modulus of rupture.”

With trees already at historically depleted levels from the exploitation for its dye wood, today’s global demand for violin bows have continued to push the species to dangerously low levels. Efforts to preserve the trees were organized even before its official listing as an endangered species in 2007. In a study of six other promising South American hardwoods, it was found that only ipe (Handroanthus spp.) produced bows of acceptable quality as a substitute.

I have some pieces of genuine Pernambuco and many of Chakte Viga, but I have serious doubts about two pieces. Not only is the intense orange color suspicious, but in my opinion the pores are too large for Brazilwood. It is also not as hard as my other Pernambuco pieces (pieces of genuine P. I cannot scratch the surface with my fingernail), and in this case it’s possible. This wood also doesn’t look like Chakte Viga, because Paela has smaller pores and fewer of them; the smell is more like genuine Pernambuco than Chakte Viga-which has a rather strong rosin-like smell… Read more »

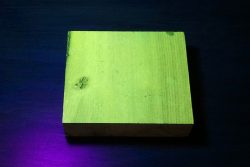

Have you tried checking the water-extract fluorescence? (See comments above in the lookalikes section under “Identification.”)

Not, but I will try

after doing the experiment, I got this effect (photo) . A distinctly green color despite the fact that the UV bulb is very weak and has only 4mm in diameter. This certainly distinguishes this wood from Chakte Viga (as Chakte v. has much, much less pigment), but what about other related species, I mean mainly Caesalpinia sappan which is very rich in Brazilin pigment? The difference in the vascular density between pernambuco and this wood is too great to conclude that it is only the effect of different habitat/growing conditions.

Personally, given brazilwood’s value, I’ve always been a little suspicious of modern sellers and their brazilwood, so I sympathize with your questions. But I really have no other explanation or alternative that the wood could be. If there’s a bright reddish water-soluble substance coming out of the wood, the bottom line is that is exactly the property that caused such a stir centuries ago and gave the wood its claim to fame. As to Caesalpinia sappan, other than coming from the opposite side of the globe, I don’t know of any way to tell it apart from brazilwood. But most… Read more »

Also, I think it would be helpful if you weighed the wood in question and got a more precise measure of its density. If it’s an irregular shape, you could try to get its volume through submerging it in water and seeing how much water is displaced.

What the fence slats looked like with the paint still on them and a picture after the paint was removed…

Just wanted to post some pictures of some really rare figured old growth Pernambuco, which was reclaimed from fencing in Brazil. This wood I estimated to be at least 70 years old if not older.

It is the most figured large boards I have ever seen to this date…

I have a highly figured board about 3′ by 1’6″ by 1″ that i got with a load container full of exotics of a now deceased cabinet maker ,I was not sure at first but my mother identified it for me when i sent her some shavings of various woods for her to try with her natural wool dyes ( mothers eh ! where would we be without them )

Here it is under the black light.

I have a piece I bought from an estate sale, I think it may be pernambuco. There’s no aroma when working it. I put it under the blacklight and it has a faint green yellow glow. The color when freshly worked is a lighter orange red and the aged sides are a deep brown red. Did I get lucky

I would say the fact that it fluoresces under a blacklight would show that it is NOT pernambuco. Also, the pores look too large and there is too much marginal parenchyma present. To me, it looks closest to jatoba, but diffuse porous tropical hardwoods like this can be hard to ID.

I have a piece I bought from an estate sale, I think it may be pernambuco. There’s no aroma when working it. I put it under the blacklight and it has a faint green yellow glow. The color when freshly worked is a lighter orange red and the aged sides are a deep brown red. Did I get lucky?

Yep, that’s pernambuco.

This Brazilwood (Pernambuco) piece was turned from a shipment imported to the USA long before endangered species restrictions were put in place. Great wood for ornamental embellishments and fancy detailing.

Pernambuco is also known to clog band saw blades and drum sanders due to the wood’s oils. As I mentioned before it is easily scraped unlike sanding.

More work should be done to expose the people who financed the destruction of Brazilwood trees!

Unfortunately they are probably long since dead , it is a very hard tree to cultivate and by the time the damage was done it was already too late , the Brazilian government do work very hard to protect these trees and all the trees of the amazon under their control , but sadly illegal logging is still a huge problem

Just some information about the work ability of Pernambuco my friend Dan Maloney, a guitar builder discovered:

Pernambuco is very is very easy to shape using scrapers and shaves off pieces very well. When sanding it however, he found it easily clog sandpapers. He also said it is somewhat of a brittle wood, so care must be taken when routing Pernambuco.

A beautiful guitar.

Thanks!

Two questions: which of the woods used in the neck are Pernambuco? Did Dan use Padauk also? I have an old slab of wood supposedly for violin bows, but it is so bright red/orange that I’m thinking it must have been dyed or it’s possibly padauk. Thanks.

Actually I just looked at a piece of padauk and that’s not what I got.

The different contrasting colors, Orange and Red, are all Pernambuco, but different shapes of color. The black contrasting piece is dyed holly.

Hello! Any ideas of a substitute for making instrument bows? I guess it’s a matter of weight, hardness and elasticity?

Ipe, which is much cheaper, but not as pretty. It is sold as flooring and can be had for as little as $4.00 per bf.

Thanks, I’ll try!

It seems to be much less responsive to steam bending though, from what I read.

Pernambuco also has the unique ability to bend by heating.

Hello, I’m Brazilian and I’m a forestry engineer. The reason why Brazil wood is used for the violin bow is its unique elasticity, which allows some musical notes to be hit with the brazilwood bow

watch this video: https://www.youtube.com/watch?v=9W-aoE8_Lck

I’d love for you to recommend an alternative wood for bow making. I won’t use pernambuco if I can find something else, I’d love to ease the demand for pernambuco in your country.

I suggest Caesalpinia paraguariensis (so-called “brown ebony’). It’s a close relative of Caesalpinia echinata (known as “pau brasil”, “pernambucowood”, or “brazilwood”), and has comparable mechanical properties. [caution: in the violin business the name “brazilwood” is mostly used for an unrelated tree Manilkara bidentata, from which great numbers of inexpensive bows are made]).

oh dear,I’ve just bought a bow made of this wood.Am I adding to this species’s demise,I wouldnt have done so had I cheked the database first

I just picked up a piece from a local shop, I didn’t even know what it was.