DATA SOURCE(S): 1,5,8,14,36

Common Name(s): Sapele, sapelli, sapeli mahogany

Scientific Name: Entandrophragma cylindricum

Distribution: Tropical Africa

Tree Size: 100-150 ft (30-45 m) tall,

3-5 ft (1-1.5 m) trunk diameter

Average Dried Weight: 41.6 lbs/ft3 (665 kg/m3)

Specific Gravity (Basic, 12% MC): 0.56, 0.67

Janka Hardness: 1,360 lbf (6,060 N)

Modulus of Rupture: 16,070 lbf/in2 (110.9 MPa)

Elastic Modulus: 1,790,000 lbf/in2 (12.35 GPa)

Crushing Strength: 8,540 lbf/in2 (58.9 MPa)

Shrinkage: Radial: 5.2%, Tangential: 7.2%,

Volumetric: 12.9%, T/R Ratio: 1.4

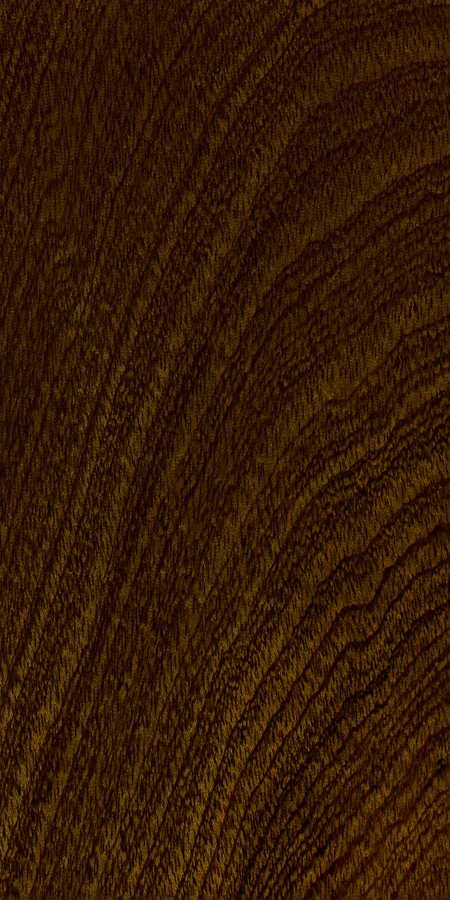

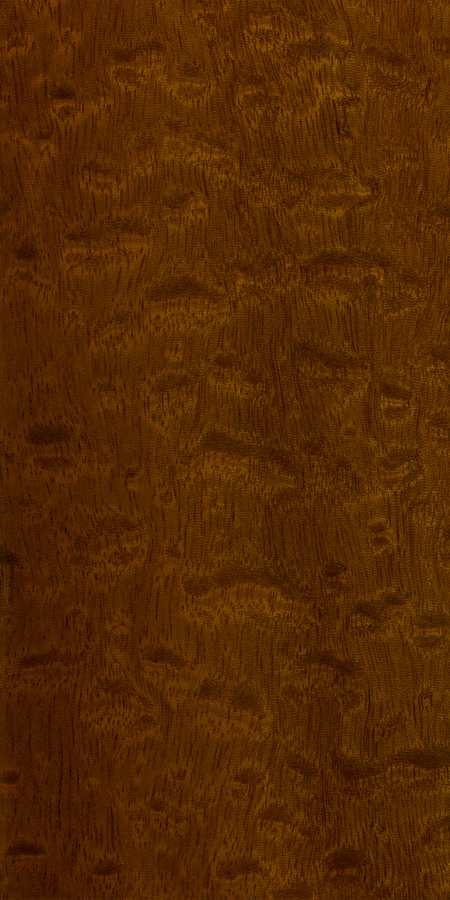

Color/Appearance: Heartwood is a golden to dark reddish brown. Color tends to darken with age. Besides the common ribbon pattern seen on quartersawn boards, sapele is also known for a wide variety of other figured grain patterns, such as: pommele, quilted, mottled, wavy, beeswing, and fiddleback.

Grain/Texture: Grain is interlocked, and sometimes wavy. Fine uniform texture and good natural luster.

Rot Resistance: Heartwood ranges from moderately durable to very durable in regard to decay resistance. Moderate insect/borer resistance.

Workability: Sapele can be troublesome to work in some machining operations, (i.e., planing, routing, etc.), resulting in tearout due to its interlocked grain. It will also react when put into direct contact with iron, becoming discolored and stained. Sapele has a slight blunting effect on cutters, but it turns, glues, and finishes well.

Odor: Sapele has a distinct, cedar-like scent while being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, sapele has been reported as a skin and respiratory irritant. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Should be moderately priced for regular flatsawn or quartersawn lumber, though figured lumber and veneer can be extremely expensive, particularly pommele or quilted sapele.

Sustainability: This wood species is not listed in the CITES Appendices, but is on the IUCN Red List. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation.

Common Uses: Veneer, plywood, furniture, cabinetry, flooring, boatbuilding, musical instruments, turned objects, and other small wooden specialty items.

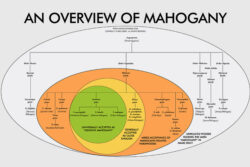

Comments: Usually pronounced (sah-PELL-ey) or (sah-PEEL-ey). Sapele is a commonly exported and economically important African hardwood species. It’s sold both in lumber and veneer form. It is occasionally used as a substitute for genuine mahogany, and is sometimes referred to as ‘sapele mahogany.’

Technically, the two genera that are commonly associated with mahogany are Swietenia and Khaya, while sapele is in the Entandrophragma genus —though all three are contained in the broader Meliaceae (mahogany) family, so comparisons to true mahogany are not too far fetched.

Images: Drag the slider up/down to toggle between raw and finished wood.

The samples below show examples of flatsawn, quartersawn, and pommele grain patterns, respectively.

Full board scan

(36.1″ x 8.5″ / 92 cm x 22 cm)

Full board scan

(23.2″ x 5.8″ / 59 cm x 15 cm)

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; growth rings sometimes discernible due marginal parenchyma and decrease in pore frequency

Arrangement: solitary and radial multiples

Vessels: large, few; reddish brown deposits occasionally present

Parenchyma: diffuse-in-aggregates, unilateral, vasicentric, and banded (sometimes marginal)

Rays: narrow to medium width, normal spacing; rays are generally not visible without magnification

Lookalikes/Substitutes: There are a number of other commercial woods in the Meliaceae (mahogany) family that can bear a close resemblance to sapele. Most mahogany-like woods are scentless and can be separated from sapele on the basis of odor. However, bosse (Leplaea cedrata) is a closely related African hardwood that can have similar appearance and scent. Separation can be difficult, but bosse generally is lighter in color, and has more extensive and consistent parenchyma bands—with the bands in sapele being more sporadic.

Other woods in the Entandrophragma genus can be very difficult to distinguish down to a species level, particularly utile (E. utile)—a very similar wood that typically lacks the fancy grain patterns sometimes seen in sapele.

Notes: Storied rays (producing ripple marks on flatsawn surfaces) present in approximately 60% of samples.[1]Richter, H.G., and Dallwitz, M.J. 2000 onwards. Commercial timbers: descriptions, illustrations, identification, and information retrieval. In English, French, German, Portuguese, and Spanish. … Continue reading

Related Content:

References[+]

| ↑1 | Richter, H.G., and Dallwitz, M.J. 2000 onwards. Commercial timbers: descriptions, illustrations, identification, and information retrieval. In English, French, German, Portuguese, and Spanish. Version: 9th April 2019. delta-intkey.com |

|---|

I had a sapele wood top installed on a bathroom countertop several years ago. Recently, a hairspray can was left on the top, leaked, and left a black stain. I’ve tried removing with Oxalic Acid which did not work. Any suggestions as to how to remove would be greatly appreciated. Thank you.

Can anyone tell me the fire spread rating for Sapele?

Using Sapele/Ribbon Sapele to make laminated beams for a sailboat. 9 x 5 mm/25 mm wide strips creating a light-dark pattern. The wood bends easily into a gentle arch and glues with Raka 2/1 Epoxy fantastic! I am also using it on Cleat and as floor timber’s on Bulkheads. I love this wood!

I am putting shutters on my house in northeast. The contractor said to choose between cedar or sapele wood. Which is better for exterior shutters?

We have contractors down in Charleston that swear by Sapele over cypress which is most commonly used down here.

Thank you!!

I just bought a house with Sapele, Canarywood, and Calico Hickory cabinets in the kitchen, living room and Bathroom. Can someone please tell me what is best for cleaning and polishing it? I would like to take good care of it all.

Murphy’s Oil Soap is the only thing I recomend for cleaning all woods

I purchased a butcher block countertop made of Sapele. I’m planning on using it for a countertop outdoors by my grill. What would be the best finish for outdoor use? Also will the sun and snow affect the wood? Will the pieces pull apart?

Is the butcher block put together with an exterior glue? If it’s in interior glue, long term exposure to the elements may cause the glue joints to fail over time. Will it be used for food prep? If yes then food safe finishes will be the limiting filter in your search.

I purchased it glued already so not sure about the glue. It will be attached to the grill but I won’t be putting food on it.

For non-food applications your choices are many. If you want a film forming product there are many exterior UV inhibited polyurethanes in various different sheens. If you are looking for a matte finish then there are many UV inhibited penetrating oils that are available from vendors like, (in no particular order), Penofin, Sikkens, Flood, etc. Your local paint store should be able to guide you with what is available in your geographic area.

Thank you Tom

Depending on money, time and experience level with finishing there are many different products that can be brushed or rolled on with UV protection. However if you really want to give it an extremely durable and lasting finish I would go with epoxy. You can buy a good 2 part brand, I like West Systems, where you mix the resin and hardener and roll or brush it on. After letting it cure lightly sand it and coat again. I would put at least 5 coats but the more you put on the better the protection and it gives you thickness… Read more »

Shawn thank you very much for your reply in information, I really appreciate it. I will look into the epoxy. Thx again Guy

We made front doors out of this wood! Looks beautiful

I have a Martin guitar made of Sapele. So beautiful and sounds amazing.

My husband built a picnic table and stools out of sapele

What did he finish and seal that table with?

someone knows if sapele can make a good bow?

I built this elliptical shaped end table from Sapele wood…then put a French polish on it. The first coat was a 4-1 mix of dried amber lac shells and alcohol which helped to seal and close the pores. The next step was to rub in an 8-1 mix of amber lac shells and alcohol. The first couple of coats were done using pumice stone powder to help smooth and fill with olive oil as lubricant. The next and final coats were rubbed in using rotten stone powder and olive oil. This combination resulted in a final finish remarkably beautiful and… Read more »

I had sapele countertops installed a few months ago. I would love to keep the finish food safe, but the three or four coats of beeswax I applied is faded and getting dull. Also, it’s hard to keep crumb free, as the finish is not really smooth. My contractor sanded it well before I started applying the wax, but it doesn’t seem smooth any more. Is there a better finish that would still be food safe, and do I need to sand it again? Any advice is helpful. Didn’t expect it to require so much maintenance.

Pretty much any finish is going to be food-safe. Polyurethane is. I would expect you have to resend it before you apply another finish they may not stick to the wax.

Odies Oil, plant based, non toxic, food safe, resists water and stains. It’s a wood stabilizer and protects against UV.

You will not be disappointed.

There is a lot of info on Odies oil and the owners are the nicest people.

Hard for me to imagine a finish that is not food safe ONCE IT HAS CURED. I think it is the “hardeners” that are dangerous.

You should look into hardwax-oil. Foodsafe, doesn’t yellow and impervious to water, acids (coca cola, wine, etc) and heat once it’s cured. It’s as hard as epoxy once cured but unlike epoxy or polyurethane finishes is incredibly easy to repair as surface do not require stripping back but just a light, localised surface sanding before reapplication. Traditionally used on timber flooring because of these properties, it is also an excellent furniture-grade finish and perfect for kitchen countertops. Has been used for quite some time in this regard in Europe but is only just starting to catch on here in Australia.… Read more »

I’m a fan huge of hardwax finishes as well, but the truth is they are by no means as durable as a poly or epoxy finish. They are by all means acceptable in my opinion for furniture and even floor finishes but they don’t have as hard of a finish as poly or epoxy and water or stains can penetrant the finish if left to long. Are easier to repair than the poly and epoxy? That is debatable and I would say in some case yes but as a blanket statement I think it is misleading to say you can… Read more »

vegetable oil works will however it has to be done properly otherwise the oil gets sticky and doesn’t work well. you should apply it then with a clean rag wipe off the excess oil.

I always use a shellac sanding sealer first, light sand with or 0000 steel wool or 320 paper then apply Bri- wax ( name brand )

Hello. I wouldn’t personally put a Wax finish on a countertop none are really penetrating or hard enough. For a counter top I would probably use either Danish oil or what we call in the UK mineral oil which we often use on cutting boards too. Oils will soak in better and give a harder surface.

Mineral oil mixed with beeswax makes a nice finish for food safe surfaces. But, you’ll need to renew it on a regular basis.

I am just about to make a kitchen dinning table with Sapele. Would appreciate any advice on the suitable finish.

I am think of a few coats of danish oil, then finishing off with solvent-based polyurethane. My only reason is that I used the polyurethane on beech before, which look nice and also quite tough for everyday use in the kitchen. but not sure how it may turn out for Sapele.

If it were me, I would apply a grain filler to the wood before final finishing, especially for a table top, but that’s just my aesthetic preference.

Your advice is much appreciated.

A question: Before applying grain filler + top coat, is there still any merit to rub in a few coats of danish oil?

If I remember correctly, danish oil is linseed-based, so I think it may serve to accelerate the patina of the wood a bit if that’s something you would want.

I made a dining table with a sapele top and finished the tabletop with three coats of boiled linseed oil on the top, bottom, and sides, and 10 coats of polyurethane on the top with 2 coats on the bottom and sides. I compared boiled linseed oil to danish oil and pure tung oil on some smaller pieces of sapele before choosing boiled linseed oil. However, any of these three oils would have looked great. I applied the oil to the bottom first, then turned the tabletop over and coated the top. Then I repeated this process with the polyurethane,… Read more »

Hats off to your patience and love to the wood and table you are making. I am still working on the table top. I took Eric’s advice and applied grain filler before polyurethane, 3 coats each side so far and probably a few more to finish the table. After sanding down, the bare sapele looks quite porous, so seems to me a good idea to use grain filler to fill the pores before applying top finish. In UK (where I live), the closest match I could get was mahogany grain filler, so the wood turns a bit reddish, but feels… Read more »

I finished 4 kitchen chairs with boiled linseed oil + oil-based polyurethane (3 coats), which made the chairs slightly darker/richer than the table (grain filler + Polyurethane). From my experience, both methods can finish Sapele with super smooth surface and stood up so far for the heavy use in the kitchen, but oil+polyurethane is easier to apply.

Can I use this in the vegetable garden to make trellises and tuteurs without worry of toxins?

I don’t think it glues well at all. First wood I had problem gluing

Medium woods, cedar, not oily, always stick very well. It is similar to freijó, a medium density wood, whose resistance is exceptional, in addition to its beauty.

I just made a cutting board with some sapele offcut I got for free!

This is outrageously stunning!

this is a BEAUTIFUL wood! I absolutely love it to sawdust and use it for all my decorative pieces. My friend used a Sapele log to make a table with a piece of toughened glass on it. Its so natural and STUNNING!!!

This seems like it would be a perfect wood for a baseball bat. Has anyone ever used it for that purpose?

I work at a lumberyard in NJ and I sell a lot of sapele. I love Sapele but it’s a typical mahogany and I don’t think it’ll hold up like Ash or hard Maple that bats are traditionally used and now currently used. I just feel like it’s too soft. Ripping Ash, H Maple and Sapele on the table saw are very much different. Just my thoughts.

I made a few very nice lacrosse sticks with it.

What’s the best wasy to stain or dye sapele to a dark mahogany color. Large door panel 40? X 87? X 5/4

I’ve just made some pieces out of Sapele and after about 7 coatings of Tung oil, the finish is so deep and luxurious, very reminiscent of mahogany. No staining, but I’m sure you could use a mahogany wipe on type finish, or a mahogany stain followed by several coatings of Tung oil, or Danish oil, or whatever you prefer. I see you posted your question in September, so I imagine you went ahead and finished your door by now. How did it come out?

I second the Tung Oil. Juts did 8 coats on a plank of Sapele. Looks great.

Pain in the butt to stain due to grain going in every direction and density variation in the same piece. The oil-stained table looks blotchy and cheap, different dark spots move depending on a viewing angle. A better option is wood die rather than stain – it produces a more even color.

Agree about unexpected color variations when finished with plain Watco Tung oil. Some pieces of my glued up planks for table top of African mahogany ended up much darker than others in spite of all looking same shade before finishing.

Question from a friend; when steam bending Sapele for the sides of a 3/4 guitar it seemed to develope blackish purple mold spots. Is this normal for sapele? Is his bending pipe dirty? Can send photograph.

As mentioned on this site, Sapele stains when in contact with iron. I had a 1.5 inch board that had forklift contact stains that went almost all the way to the other side of the board. Wouldn’t come out. This may be your friend’s problem due to contact with his bending pipe.

I am having a guitar made with Waterfall Sapele

By a very competent luthier. Has anyone had experience with such? Should I be worried about cracking? Oh by the way tried to post an image if you upload too many images the max is one it won’t let you remove the extra image to allow for one.

I’m making one with Sapele. I read an article saying that Sapele was a dead ringer for Mahogany. It’s not. It’s much harder. I had some problems routing the outline. It shattered the lower point of my RG shaped body. I had to repair with epoxy and Sapele shavings. Tonally, I think it’s going to be more in line with ash. I’m interested how yours turned out? What does it sound like. Whatt type of neck and so forth. Mine is in it’s finishing stages.

We recently built a large wood sculpture using 4″ thick by 6″, 8″, 10″, and 12″ wide Sapele timbers. The timbers are standing on end and were glued and mechanically fastened in an interlocking pattern. The piece was then sculpted. Before setting the piece in it’s permanent outdoor location, three coats of tung oil (Waterlox Marine Sealer) were applied. The piece has been outdoors on display not quite three months as of this writing. Many of the joints have opened up considerably, along with some checking and splitting on the timbers. Will the movement persist and the gaps in joints… Read more »

Hello, I’m a small business owner and I machine out solid wood wind type instruments. I’m trying to get into more exotic type woods, like this African Sapele, over my standard maples and oaks. (I have five 1’x6″x24″ blanks of the stuff) However, I use all natural beeswax to seal my completed products by heating it (and the wood to reduce warping or splitting) and boiling the instrument in the wax. Gives a great finish and mellow tone, but I’ve found some of the harder woods like to try and crack anyway if I don’t do a multi dip process.… Read more »

Dear Sir,

Can we use this SAPELLI WOOD [Entandrophragma cylindricum] for Doors and Window Frames ?

Please help me out with this

We use it often for doors, door frames, mouldings

I am

Wondering if sapelle is compatible with radiant heat flooring?

I am having some wooden windows in our home replaced. They will be painted. The Joinery company I’m using has selected Sapele for the job. Is a wood that with such a beautiful grain the right choice for window framing that will just be covered up?

No; they’re just racking up the bill on you.

Actually Sapele is the best new wood option for repair, restoration or fabrication of traditional Double Hung Sash Windows. It’s what we use in Texas and other than old growth or 2nd growth Spanish Cedar, Cypress and maybe Southern Yellow Pine, it’s one of the few woods that will hold up to the heat and humidity here. We don’t use glue on the joinery we use hardwood square pegs. It’s not uncommon and if your Joinery company has suggested it, then they really do know what they are doing.

Dear all

How to match color or fill nail holes veneer while polishing work. Please advise.

Mix sapele sawdust and wood glue. Fill the hole, sand once dry.

Garners Workshop Cambridge UK

Sapele is variable in grain and colour select to suit job in hand

Yes the turnings are Oak

Nick

I was purchasing QS boards and found one in the racks that was a different that all the others. It’s very close to a pommele but maybe not perfect enough to be sold as such (which this lumber yard doesn’t sell anyway). I knew it was going to be absolutely beautiful. They charged the same as the QS because they had no other category. It was a 14-¼” x 109″ 4/4 S3S at $5.10 bf. It was a waste of beautiful lumber, but I was making tambour door breadboxes for Christmas gifts and used most of this just to make… Read more »

The stain/varnish applied to your sapele may be blistering because it was never treated with a stripper prior to applying the stain. Sapele mahogany should be cleaned with a Trisodium Phosphate Solution before applying any stain. This strips the tannins from the wood, opening up the surface to fully accept a stain. It also removes any residue from the milling process where wax or oils may be present from the machines used to shape/cut the material.

We put together this write up comparing Sapele vs African Mahogany vs Utile if that might be helpful. For people comparing the different options.

https://thompsonmahogany.com/african-mahogany-vs-sapele-vs-utile/

Thanks

Paul

What’s the best wasy to stain or dye sapele to a dark mahogany color. Large door panel 40″ X 87″ X 5/4

That would depend on what you’re planning on using to topcoat/finish the wood with.

I have been making coat racks/hooks from some sapele shelves that were being thrown out. After sanding down using 1000 grit I have applied a coat of Boiled linseed oil, once dry rub gently with 0000 wire wool. Add another coat of oil and rub with wool again. The effect is amazing and certainly resembles rich dark mahogany.

Most british kilns will not dry below 12% because it would be pointless. As soon as the timber leaves the kiln it would be exposed to an average air moisture content of above 18% so short of shrink wrapping it is going to absorb between the kiln and retailer/ wholesaler. Most joinery in Britain will be done around 14%. There are exceptions but these tend to be specialised users.

I work with Sapele almost daily in a custom door manufacturing plant. We ship our work all over the U.S. so moisture content is always an issue. The problem seems to be that the wood we have been receiving has been in the 11-13% range, not the 9-10% we believe to be a more correct range. I have recently heard that the euro mills that kiln dry most of our U.S. wood only dry to 12% Has anyone heard of this being true, or should I expect to see 9-10% wood from my supplier? Any feed back would be helpful.

I just picked up a 4/4 x 18″ board to build a cellarette. The moisture measures 14% with a capacitance meter, but <6% with a pin meter. I tend to believe the cap meter. I rough cut the pieces and will sticker them with a fan running for a couple of weeks, measuring the moisture every other day and writing it on a strip of tape on each piece. That way I can watch the change. My basement has a dehumidifier built into the HVAC system and I keep it set at 50% RH.

OK – both meters were wrong. I cut a small piece of the sapele and measured it carefully with both meters. The PSI pin meter showed less than 6%, measured both on the face of the board and the freshly cut end grain. The pinless Wagner meter showed 12%, corrected for specie. The piece I used for the test was a 1″ strip across the board. I used the short dimension in order for the moisture to escape faster through the end grain. I first weighed it to the nearest 0.001g. Then it went into the microwave for periods of… Read more »

We’ve used Sapele for our custom doors since we can’t get the quality of mahogany from the good old days. Sikkens Cetol 1,23 system or Cetol Door & Window is what I’d recommend for finishing Sapele. Vertically it is not too problematic to keep a finish on. Horizontal installations are another phenomena.

Chris you cal lay out the cabinet doors in brigght light (not direct sunlight though) and they probbley will even out. They may darken some but should even out in color.

I operate a retail building supply and special ordered six sheets of 3/4″ sapele plywood for a home owner. He carefully cut and banded his sheets to acheive a sequence pattern for his kitchen cabinet doors. For approximately two weeks the uninstalled panels were stacked with small sizes on top of larger in a room about twenty feet from the nearest window. To his horror he discovered a shadowed outline of the shape of each panel that covered the next. I was told Sapele is very photo sensitive. He is searching for ideas to salvage his work. P.S. I will… Read more »

Dear, Is there any one who can send me photos of Pomelle Sapele/Quilted sapele logs …how its look like …only quilted sapeli logs photos…….I am awaiting for may be some ones kind can reply soon …thanks.thanks

It sounds like the finish is the problem, and not necessarily the wood? Is the Sapele cracked or otherwise deformed?

If it is just the finish, I’d recommend stripping off the old finish, sanding it down to bare wood, and then refinishing it with several coats of a spar urethane for good protection from the elements.

Hi there, could you tell me what is the best way to presenve and revive sapele wood on the exterior of my house?

I have patio doors and others doors made of sapele and they have gone horrible and whatever was put on them to treat them has gone all blistery.

I would appreciate your advise,

Thank you very nuch

Nazare

I’ve installed bunks on a 135 foot schooner made of sapele and have used Daly’s FloorFin and it has held up very well. Some of their other products have not been as advertised, but I put this product on the soles and the bunk faces and bulkheads and after a couple hundred days of use have been very impressed. I’m just adding a couple of coats this winter and look to use if in the far future. It brings out the wonderful glow of sapele as well.

https://www.dalyspaint.com/store/index.php?main_page=product_info&products_id=12