DATA SOURCE(S): 1,8,15

Common Name(s): Pau ferro, morado, Bolivian rosewood, santos rosewood, caviuna

Scientific Name: Machaerium spp. (primarily M. scleroxylon)

Distribution: Tropical South America (mainly Brazil and Bolivia)

Tree Size: 65-100 ft (20-30 m) tall,

3-5 ft (1-1.5 m) trunk diameter

Average Dried Weight: 54 lbs/ft3 (865 kg/m3)

Specific Gravity (Basic, 12% MC): 0.7, 0.87

Janka Hardness: 1,960 lbf (8,710 N)

Modulus of Rupture: 17,750 lbf/in2 (122.4 MPa)

Elastic Modulus: 1,574,000 lbf/in2 (10.86 GPa)

Crushing Strength: 8,830 lbf/in2 (60.9 MPa)

Shrinkage: Radial: 2.8%, Tangential: 6.7%,

Volumetric: 9.9%, T/R Ratio: 2.4

Color/Appearance: Color can be highly varied, ranging from reddish/orange to a dark violet/brown, usually with contrasting darker black streaks. Narrow sapwood is a pale yellow and is clearly demarcated from the heartwood.

Grain/Texture: Grain is typically straight, though sometimes slightly irregular or interlocked depending on the species. Fine, even texture and a naturally high luster—though depending on the particular species, the wood can have a coarser, more fibrous texture.

Rot Resistance: Rated as very durable, though quite susceptible to insect attack, and not recommended in direct ground contact.

Workability: Pau ferro is considered overall to be of fair workability, as it can blunt the cutting edges of tools, and any irregular grain has a tendency to tearout during machining operations. Also, many of the same challenges in gluing rosewoods are common to Pau ferro as well. Pau ferro turns and finishes well.

Odor: Depending on the species, the wood may have a characteristic scent.

Allergies/Toxicity: Although severe reactions are quite uncommon, pau ferro has been reported as a sensitizer. Usually most common reactions simply include eye and skin irritation. Anecdotal evidence suggests that there is a high rate of reaction among woodworkers, and chemcial analysis of the pau ferro’s extractives would seem to support this assertion, as the wood contains a up to 2% of R-3,4-dimethoxydalbergione—a strongly sensitizing substance also found in true (Dalbergia) rosewoods.[1]Hausen, B. M. (1982). Incidence and significance of toxic and allergic contact dermatitis caused by machaerium scleroxylum Tul.(Pao ferro), a substitute wood for palisander (Dalbergia nigra … Continue reading See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Pau Ferro is in the medium price range for exotic imported hardwoods, and is likely to be much more affordable than some of the scarcer true rosewoods (Dalbergia genus), of which this wood is often used as substitute.

Sustainability: This wood species is not listed in the CITES Appendices, and many of the species within the Machaerium genus are reported by the IUCN as being of least concern. One exception is Machaerium villosum from Brazil, which is reported as vulnerable due to deforestation.

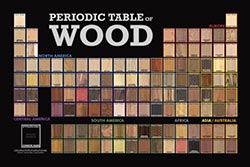

Common Uses: Veneer, musical instruments, cabinetry, flooring, interior trim, turning, and other small specialty wood objects.

Comments: Pau ferro is a wood of many names, and is sometimes called morado—and because the wood is so similar in appearance and working properties to rosewood, it is also sometimes referred to as Bolivian or Santos rosewood. The wood has been used in various capacities as a substitute for the endangered Brazilian rosewood (Dalbergia nigra).

Although the wood is not technically in the Dalbergia genus, pau ferro (Machaerium species) is botanically very closely related to true rosewoods, both being subdivided within the Fabaceae family into the tribe Dalbergieae and even further into the subclade Dalbergia.[2]Lavin, M., Pennington, R. T., Klitgaard, B. B., Sprent, J. I., de Lima, H. C., & Gasson, P. E. (2001). The dalbergioid legumes (Fabaceae): delimitation of a pantropical monophyletic … Continue reading Additionally, the pau ferro contains the same sensitizing compounds found in rosewoods[3]Hausen, B. M. (1982). Incidence and significance of toxic and allergic contact dermatitis caused by machaerium scleroxylum Tul.(Pao ferro), a substitute wood for palisander (Dalbergia nigra … Continue reading—it’s about as close to a true rosewood as a species can get without actually being a Dalbergia species.

Images: Drag the slider up/down to toggle between raw and finished wood.

The first two samples are of Machaerium scleroxylon—the first sample shows a standard striped piece with sapwood, while the second sample has very subtle beeswing figure, and the third sample is of M. villosum.

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; growth rings are sometimes discernible due to marginal parenchyma and decrease in pore frequency in latewood

Arrangement: solitary and radial multiples

Vessels: medium, moderately numerous to numerous; dark brown heartwood deposits occasionally present

Parenchyma: can vary a lot depending on species; sometimes only vasicentric and/or with marginal bands, while other pieces may have winged, lozenge, and confluent parenchyma, along with more extensive banding

Rays: narrow width, normal to close spacing; rays generally aren’t visible without magnification

Lookalikes/Substitutes: This wood is sometimes used in place of Brazilian rosewood, as well as other CITES-listed listed rosewoods. However, in addition to the difference in odor when being worked, pau ferro is also usually easily distinguished from Dalbergia species on account of Machaerium species’ smaller and more frequent pores.

Notes: None.

Even though the Machaerium genus currently contains over 120 recognized species, only a few are commercially harvested—the rest are fairly obscure or are only used locally.

Related Content:

References[+]

| ↑1, ↑3 | Hausen, B. M. (1982). Incidence and significance of toxic and allergic contact dermatitis caused by machaerium scleroxylum Tul.(Pao ferro), a substitute wood for palisander (Dalbergia nigra All.). Der Hautarzt; Zeitschrift fur Dermatologie, Venerologie, und Verwandte Gebiete, 33(6), 321-328. |

|---|---|

| ↑2 | Lavin, M., Pennington, R. T., Klitgaard, B. B., Sprent, J. I., de Lima, H. C., & Gasson, P. E. (2001). The dalbergioid legumes (Fabaceae): delimitation of a pantropical monophyletic clade. American Journal of Botany, 88(3), 503-533. |

I work with restoring retro furniture and during my work I’ve fallen in love with the look of Brazilian Rosewood (Rio-Palisander), but given it’s highly endangered status, I wouldn’t buy any, even if I could, as it only facilitates further deforestation. I would though love to use this close relative instead, but I’m finding it ridiculously hard to find just EU suppliers that both sell to private individuals, ship to my native country of Denmark and offers lumber that’s thicker than 25 mm, as I know I’ll have to remove further material to get the final look I want. This… Read more »

These anatomies do not correspond to the species described.

Here in the Brazil’s Northeast, we call it jucá”

I have a comment on the toxic nature of Pau Ferro. I am midway through building my first acoustic guitar using this wood for the back and sides. I hand scraped and sanded the sides and back to the required thickness and took the precaution of wearing gloves and a mask and frequent dust collection during the process. The day after bending the sides I developed a serious rash and blisters over the back of my hands, and forearms and a reaction on my face and neck. I had to adjust one bend which had not come out correctly and… Read more »

I have used Pau Ferro for a telecaster fretboard (I make electric guitars as a hobby), as well as Indian Rosewood. It is the equal of any other tropical hardwood, including Indian Rosewood in my opinion. It is deffo not a cheap subsititute, it stands on its own as an excellent wood for musical instruments. It is a beautifully grained wood, excellent for fretboards.

Constructed a classical guitar with back and sides of Pau Ferro. The bending and joinery with this wood went relatively smoothly. It has beautiful grain and finished extremely well with a French Polishing of blonde shellac.

Hey Frank, that looks awesome! What wood did you use for the neck? It has a cool gray color :)

Thanks Colby.? The neck is book-matched black walnut with a centre maple strip.

A turned platter from santos rosewood

Wikipedia says Pau Ferro is Libidibia ferrea (formerly Caesalpinia ferrea), not Machaerium scleroxylon.

It doesn’t have a page on Machaerium scleroxylon. It does have a page on the genus Machaerium, which lists Machaerium scleroxylon, but doesn’t have much to say about it.

I see that these are in the same family, Fabaceae (legumes), but different genus. Genus Libidibia vs. Subfamily Faboideae, Tribe Dalbergieae, Genus Machaerium.

stew-mac, the guitar parts supplier, agrees with you (Pau Ferro = Machaerium scleroxylon).

Common names are, in my opinion, almost completely useless when it comes to these sorts of situations. I’ve actually considered just renaming this page to morado just to avoid confusion. There are a great number of woods that go by the name pau ferro, which roughly translates to iron wood. In this instance, there is no “right” answer. Much like the English language name “ironwood” there are almost as many species of ironwood (or pau ferro) as there are different geographical regions where heavy wood is found.

https://powo.science.kew.org/taxon/urn:lsid:ipni.org:names:505578-1

says that the common names for Machaerium scleroxylon are: Cabiuma, Cabiuna, Caviuna, Jacaranda, Jacaranda-cabiuna.

https://powo.science.kew.org/taxon/urn:lsid:ipni.org:names:77100755-1

says that the common names for Libidibia ferrea are: Leopard Tree, Pau-ferro.

I think that wood-database doesn’t have a page for Libidibia ferrea.

I do have a piece of Libidibia ferrea but have not added a page on it yet. It should be very similar to this wood: https://www.wood-database.com/brown-ebony/

A care is necessary when talking about tree/wood name, because a tree can have a name and the wood another totally different. The name Jacarandá usually refers to similar trees from the Machaerium Genus and the Dalbergia Genus, both from the Family Fabaceae (Leguminoseae), Subfamily Faboideae (Papilionoideae), Tribe Dalbergieae. A lot of caractheristics such as philotaxy, flowers, tree size are very close to each other. The fruit is a little different, but essencially the same. They’re both samaras, but Machaerium ones are like Maple, with the seed located on the end of the fruit and Dalbergia, on the center. The… Read more »

Thanks for that, and you’re totally right on the common names. I’ve been considering renaming this page from “Pau Ferro” to something less ambiguous.

Heres is my story… I selected some boards to make a bartop out of. Roughly 20 sq. ft. in size. I joined the boards and proceeded to sand the joints flat. Unaware of the affects to come I went unprotected, no mask or barrier suit. The first night I sanded for several hours in an open garage, breathing the dust with no restrictions. Later that night I woke up with breathing problems and a swollen throat, luckily made it through the night. The next day I had sneezing and coughing all day. Decided to wear a mask on the second… Read more »

I make pocket knife handles with this wood all the time and it is one of my favorites to use, it polishes up nice and looks great. I typically just apply beeswax to finish, just finished this one today.

Just got a new Fender Bass with a Pau Ferro board. Got lucky and got one with some rather nice figuring… almost Zebrawood-esque.

i am a recorder player and very interested in tonewoods, especially for woodwind instruments. Obviously, becauses of CITES and general sustainability issues, some of the tropical hardwoods such as the Dalbergias are harder to source. I think the German recorder maker Mollenhauer tried to replace Dalbergia nigra with Morado some years back but had to discontinue because of allergic reactions. The rosewoods, in general as used for woodwinds (you put it in your mouth, after all) are somewhat problematic for many players. Usually there are no problems with fruitwoods such as pearwood, plumwood or cherrywood. The tropical hardwoods do produce… Read more »

Frank,

Can you share how can one make a woodwind instrument, using Rosewood (Dalbergia Latifolia).

Leonard

This is in German, but you can see how ebony is turned and drilled, making Irish bagpipes.

https://www.youtube.com/watch?v=bXyaDouUgUY

I see that American Persimmon is not mentioned as an alternative to some tropical hardwoods.It’s in the Ebony family,is very hard and has been used with fine results as a fingerboard for musical instruments.It could be grown easily throughout the lower 48 states and produces tastey fruit as a by product.It spreads all over the place and forms groves naturally.I think it needs more encouragement as a fine wood.It is not black and some call it blond Ebony.You can stain it black but what’s wrong with the “exotic”American blonde Ebony,as is?

Persimmon has VERY high shrinkage rate. This will cause major problems on a fingerboard when all the frets pop out in winter.

Hmmm, if persimmon wood was unusually susceptible to shrinkage I doubt that golf club makers would use it for driver clubs. Persimmon is the standard wood for that purpose, because it’s heavy and very impact resistant. If it shrank materially any golf club made with it would likely fall apart at some inopportune time such as during a Master’s tournament. I suspect that shrinkage sufficient to cause the kind of problem you describe for fingerboards results from improperly seasoned wood, or wood glued in place during a period of very high humidity. If the latter, almost any wood will show… Read more »

You can’t be serious. Golf ‘woods’ haven’t been made from wood in years aside from replicas of antiques.

And shrinkage effects different shapes and grain alignments differently. What is acceptable for a lump may not be for a plank.

I am using it to build picture frames and it is gorgeous! I inset Curly Maple to set off the dark red color. All of the joints and slots in the biscuit cut edges were thoroughly cleaned with lacquer thinner until the oil no longer stained the paper towel or Qtip, then glued with epoxy. Ditto for the finish, I wiped it with lacquer thinner then applied sanding sealer twice, sanded with 220 grit between each coat, then 5 coats of Epifanes varnish sanded with 400 grit between coats. The chatoyance is beautiful.

Using it for electric guitars isn’t a negative. But i is very heavy.

Pau Ferro, although having visual similarities to rosewoods is no rosewood, doesn’t sound like rosewood and doesn’t smell like rosewood. It’s acustically rather dead material..Personally i would not use it for my guitarmaking..except maybe for a headplate if i had nothing better availlable. I think it makes not a good substitute for neither type of true dalbergia rosewoods when it comes to classical or flamenco guitars.

Actually, pau ferro is one of the most highly regarded woods for the backs and sides of acoustic guitars. It’s in very short supply and finding decent sets large enough even for classical guitars can be problematic. It’s not intended as a rosewood substitute, though the market being what it is, many makers must take pains to reassure clients that the CITES restrictions on rosewood don’t apply to all woods, and further that the CITES terms were not directed personally at that client no matter how wounded that client might feel. Brazilian and Madagascar rosewoods are in the “move on”… Read more »

Good response, making a moral and practical point without being overbearing or accusatory.

As to Pau Ferro – I believe that Fender had an announcement years ago they’d start using it across all lines, whereas before it was just in the fretboard of a single bass offering. I would be inclined to believe then that it is a suitable material for guitarmaking.

Paco de Lucía siempre utilizaba en sus conciertos una guitarra Conde de pauferro, yo tengo una y suena muy bien, recuerda al arce pero con más pegada. En las eléctricas desconozco el resultado pero es una madera muy pesada.

The Morado is an incredible wood. I like simple with oil seemseed.

My “Love Keychains” carved in Pau Ferro (Morado, Bolivian Rosewood). Very nice hardwood to work. Tends to lighten over time.

Sou brasileiro e convivo com esta madeira desde que nasci. Na juventude trabalhei em serraria de madeira e posso te garantir que Machaerium Scleroxylonm não é pau ferro. Caesealpinia Ferrea é o pau ferro. No Brasil a Machaerium Scleroxylom é conhecida como Caviúna ou Cabiúna e é a mais incrível das madeiras brasileiras pela sua beleza e resistência.

Devido à dificuldade de se encontrar Caviúna, atualmente vende-se Pau ferro como se fosse Caviúna.

Tenho uma quantidade razoável de Caviúna que adquiri de demolições .

Antonio Bruno. Você tem toda a razão. O Pau Ferro, além da densidade, oferece resistência e flexibilidade. Na região Nordeste é conhecida também como Jucá, usada para cassetes policiais nos tempos idos. Eu já fiz um bodoque de um galho de Jucá, ou pau ferro. Infelizmente e´muito usado para carvão também. Nós tínhamos Pau Ferro na nossa mata, em São Gonçalo do Amarante.

Thanks for the info on T/R Ratios – As you said quarter swan expands the most in a vertical movement, this is why is seems much more stable. I just didn’t know until now that the formula stays the same for the same wood no matter how it is swan! Thanks Rickey

The shrinkage rate of quarter swan wood is more in a radial measurement or height! Instead of a tangential measurement or width measurement! What is the formula for quarter swan verses flat or plain swan wood in T/R terms?

T/R shrinkage rates! We all know quarter swan wood is much more stable than flat swan. But the T/R ratios that we see in the wood data base, which kind of swan wood are they or you getting the T/R ratios from. What is the T/R ratios of flat swan verses quarter swan wood? They have to be different! What is the formula for quarter swan?

The T/R ratio is what it is, and it doesn’t change based on how the wood is sawn. Basically, quartersawn wood is not actually more stable in the sense of shrinkage — the wood will always shrink the same amount. It’s just that quartersawn wood has the effect of placing the dimension with the least amount of shrinkage (i.e., the radial surface) in such a way that it will seem to be more stable. For instance, with quartersawn flooring planks, each plank seems more stable because the dimension that expands and contracts the least amount is oriented horizontally, thus the… Read more »

Wood as many notables is a Respectfull species, it will show you your future very precisely as it comes from the undoubtfull past, it’s spirit calculates immaculately. Those of you who use Polyurethane on Instruments should really re-consider your carrer choice. Using poisonous compounds such as Polyurethane (developed as a side product of Zyclon B – the gas that Nazis allegedly used on Jews) WILL MAKE YOUR SKIN MORE PRONE OR SUCCEPTIBLE TO ALLERGIES, NATURAL POISONS AS WELL AS PLAY AN IMPORTANT FACTOR IN THE DEMISE OF YOUR GENERAL HEALTH!!! Stay away from Polyurethane, Nomex, (developed by DuPont also Kevlar,… Read more »

As a finish one should allways use something that is as close to the wood you are working with as possible with the least possible chemichals involved – make your own oil from Pine leaves if you don’t have any Morado leaves accessible… Beeswax works fine as well go on spend a buck you won’t ever go broke on Beeswax

you will kill millions of Bees using Polyurethane

I had forgotten how bad this wood is to finish until I am nearly done with my current project. It had been about ten years since my last attempt. It’s just so beautiful. I had to take my first coat of undried polyeurethane off. Then I coated with shellac and had a beautiful second coat of polyeurethane which dried nicely, but that marred too easily. Back to the drawing board.

Actually I came here to find answers to why my finnish has never dried and you’ve pretty much answered it except I used Shellac on several different types of wood at the same time: Buckeye burl, Redwood lace burl, asian satin wood, Padauk, and of course the morado. All were flat surfaces (guitar picks), all were done at the same time, 5 coats( half hour intervals), 24 hours, flip and repeat except I let them cure for 3 days before I had a chance to look at them…all were dry EXCEPT the Morado, which 3 and a half weeks later… Read more »

Cant use polyester on Pau Ferro, it won’t dry without a barrier coat

Ciao, io uso questo tipo di legname da tempo ma non ho mai avuto problemi. Lo uso nella produzione di sedie e poltroncine di alta qualità. Ciao.Lale

Morado makes me itch pretty bad, too. I’ve never had any problem with Polyurathane finish on this wood, nor any problem gluing. System Three makes an epoxy/resin glue called G-2 that is supposed to work pretty well. I’ve used it but never tested it by dropping it on the floor like a toughbook. However, I did try to pull it apart with my arms and it didn’t budge.

Sebastian, this is something that I want to address in an article as I get time, but finishing problems on oily woods is a common problem, and is somewhat related to the problems in gluing oily woods. It seems to affect reactive finishes like polyurethane more than simple evaporative finishes such as shellac. I once applied some polyurethane to some Cocobolo, and it simply never dried (at least not in about a month I waited). My theory is that the chemical composition of the finish is being altered when the wood leaches oil into the finish, thereby rendering it incapable… Read more »

It is my first time working with Pau Ferro, I have used a marine grade, satin oil based varnish (three coats) and it is taking forever to dry does anyone knows why or had a similar experience?

This wood gives me a serious skin reaction on my head and neck, but not on my hands (too callused?). It also does not seem to cause any respiratory problems. My head, neck and hands are the only parts of my body exposed when I turn this wood on the lathe. The hives last 24 to 48 hours. So far, I have not found an effective OTC treatment.