DATA SOURCE(S): 10,20,36,42

Common Name(s): Olive, European olive, Italian olive, Mediterranean olive, Bethlehem olive

Scientific Name: Olea europaea

Distribution: Native to Mediterranean Region; also cultivated in many subtropical regions worldwide

Tree Size: 25-50 ft (8-15 m) tall,

3-5 ft (1-1.5 m) trunk diameter

Average Dried Weight: 61.2 lbs/ft3 (980 kg/m3)

Specific Gravity (Basic, 12% MC): 0.81, .98

Janka Hardness: 2,710 lbf (12,060 N)

Modulus of Rupture: 20,740 lbf/in2 (143.0 MPa)

Elastic Modulus: 1,797,000 lbf/in2 (12.39 GPa)

Crushing Strength: 9,960 lbf/in2 (68.7 MPa)

Shrinkage: Radial: 4.9%, Tangential: 7.7%,

Volumetric: 12.8%, T/R Ratio: 1.6

Color/Appearance: Heartwood is typically yellow to light reddish brown, with contrasting darker brown to black streaks and veins. Yellowish sapwood is generally sharply demarcated from the heartwood, though it can be harder to tell apart if the heartwood lacks contrasting streaks. Overall color tends to deepen with age. Olive is sometimes figured with curly or wavy grain, burl, or wild grain.

Grain/Texture: Grain may be straight, interlocked, or wild. Fine uniform texture with moderate natural luster.

Rot Resistance: Conflicting reports range from perishable to moderately durable. Olive has poor insect/borer resistance.

Workability: Can be somewhat difficult to work on account of its density and sometimes wild or interlocked grain, resulting in tearout during surfacing operations. Olive has high movement in service and is considered to have poor stability—especially if branch wood has been used (a more common occurrence with fruit trees like olive). Turns superbly, though drying checks and warpage can occur during drying. Glues and finishes well.

Odor: Has a distinct, fruity scent when being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, olive has been reported as a sensitizer. Usually most common reactions simply include eye and skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Because of the fruit’s economic importance, healthy, cultivated olive trees typically aren’t felled for lumber. Availability is generally limited to pruned branches, trimmings, and diseased/storm damaged orchard trees. Short lumber, natural-edged slabs, turning squares, and burls are occasionally available, often from wild trees. Prices are high for an imported hardwood.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species.

Common Uses: High-end furniture, veneer, turned objects, and small specialty wood items.

Comments: Olive trees are commercially important throughout the natural regions where they grow. There are several subspecies and hundreds of cultivars of Olea europaea, with each variety producing olives of different shapes, colors, etc. either for oil production or direct consumption (i.e., table olives).

One subspecies of note is Olea europaea ssp. cuspidata, sometimes called African olive or wild olive. This subspecies was formerly considered a separate species (listed under various names, such as O. africana and O. ferruginea), though now most authors simply consider it a subspecies.[1]Green, P. S. (2002). A revision of Olea L.(Oleaceae). Kew Bulletin, 91-140. This subspecies is believed to be the ancestor to what is now the cultivated olive used in commerce today.[2]Popay, I. (2022). Olea europaea subsp. cuspidata (wild olive) [Dataset]. In CABI Compendium. The wild trees are very widespread, and are even considered an invasive species in some non-native areas.[3]Cuneo, P., & Leishman, M. R. (2006). African Olive (Olea europaea subsp. cuspidata) as an environmental weed in eastern Australia: a review. Cunninghamia, 9(4), 545-577. Some of the mechanical data listed above, particularly the strength values, come from this subspecies.

In general, olive trees are very long-lived, and a number of specimens are considered among the oldest known trees in the world. However, because the trunks of mature olive trees tend to become hollow over time, exact dating can be problematic. Carbon dating and surrounding archeological evidence is sometimes used to estimate a tree’s age, and reports of the oldest olive trees in the Mediterranean region range anywhere from several hundred to even thousands of years old—with many still bearing fruit.[4]Bernabei, M. (2015). The age of the olive trees in the Garden of Gethsemane. Journal of Archaeological Science, 53, 43-48.[5]Bombarely, A., Doulis, A. G., Lambrou, K. K., Zioutis, C., Margaritis, E., & Koubouris, G. (2021). Elucidation of the origin of the monumental olive tree of vouves in Crete, Greece. … Continue reading

When used for lumber, olive wood is generally named after its origin, with a number of names/sources commonly used, such as Bethlehem olive, European olive, Italian olive, Mediterranean olive, and Spanish olive. Although growing conditions can affect the tree and therefore the quality of the wood produced, there doesn’t seem to be much of a consistent difference in the wood from different general regions in the Mediterranean. Even the closely related East African olive (Olea capensis), while not used for olive fruit production, bears wood that is more or less indistinguishable from Olea europaea.

Not to be confused with Russian olive (Elaeagnus angustifolia), an unrelated hardwood species in a different family (Elaeagnaceae) than true olive trees.

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Steve Earis for providing a wood sample and turned photo of this wood species.

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; growth rings sometimes discernible due to decrease in pore frequency and color change of fibers in latewood

Arrangement: primarily in radial multiples

Vessels: small to medium, numerous to very numerous; yellowish deposits common

Parenchyma: vasicentric, though on most samples very little if any parenchyma is visible

Rays: narrow width, normal spacing

Lookalikes/Substitutes: With its dramatic contrasting streaks and veins, olive is sometimes confused with zebrawood (Microberlinia brazzavillensis). However, zebrawood has very large pores (giving the wood a coarse, open texture), as well as visible winged and banded parenchyma.

A lesser known hardwood more closely related (in the Oleaceae family) is lilac (Syringa vulgaris). Although lilac typically lacks the dramatic streaks and veins found in olive, lilac wood is about the same weight, and has very similar anatomical features. However, its strong floral scent differs from the more fruit-like scent of olive wood.

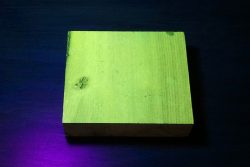

Notes: Portions of the heartwood (possibly correlated with areas of darker streaking) can fluoresce a faint to medium yellow under blacklight.

Related Content:

References[+]

| ↑1 | Green, P. S. (2002). A revision of Olea L.(Oleaceae). Kew Bulletin, 91-140. |

|---|---|

| ↑2 | Popay, I. (2022). Olea europaea subsp. cuspidata (wild olive) [Dataset]. In CABI Compendium. |

| ↑3 | Cuneo, P., & Leishman, M. R. (2006). African Olive (Olea europaea subsp. cuspidata) as an environmental weed in eastern Australia: a review. Cunninghamia, 9(4), 545-577. |

| ↑4 | Bernabei, M. (2015). The age of the olive trees in the Garden of Gethsemane. Journal of Archaeological Science, 53, 43-48. |

| ↑5 | Bombarely, A., Doulis, A. G., Lambrou, K. K., Zioutis, C., Margaritis, E., & Koubouris, G. (2021). Elucidation of the origin of the monumental olive tree of vouves in Crete, Greece. Plants, 10(11), 2374. |

Olive trees can become much much wider in diameter. I got 4m olive trees in my field. The issue is that they rarely remain straight

Amazing wood type. It is super hard and heavy wood, but difficult to dry. We are lucky here in Cyprus and we have a lot of olive wood and especially big slabs or huge round roots cookies for unique dining tables and other creations.

I picked up these two pieces of Olivewood recently from a local fine lumber supplier to use for a solid body bass guitar top. They measure around 8″ x 20″ x 7/8″, and the two pieces together weigh in at 11.5 lbs. They are very oily, even leaking a little onto the tissue they are laying on. Granted, the supply warehouse was very cold, and these were brought into a very warm house. They feel extremely dense and glass-like. The supplier told me he was not 100% sure of their origin, but thinks they came from Ukraine. Any ideas whether… Read more »

In my opinion, when it comes to olive, the subspecies (and even the species) isn’t really that relevant, or even able to be determined. Quality of olive wood can be all over the map (both literally and figuratively). In the end, I think that the highest quality olive wood is whatever looks the best. So it looks like you’ve got the good stuff!

Thanks Eric. I’ve never used Olivewood before, so I’m a little nervous about gluing and finishing it. I’ve been reading here and several other places on tips and techniques. Heat, microwave, clothes iron, paint stripper, acetone, etc.to remove the oil. Then using a non water-based polyurethane glue or epoxy. As for finishing, the popular suggestion was to seal using 3 coats of #2 shellac, then top with poly. Others have stated the shellac won’t cure, and the only option is resin. Then there is the option of using true oil, or tung oil, which I’ve considered, but would it work…… Read more »

I think with the supposed bad reputation of shellac, it stems from people not using freshly mixed shellac from flakes. You really should make it yourself instead of buying a can in a store. I’ve yet to hear of freshly mixed shellac not curing on a certain wood.

Sorry, Forgot the side view.

First time building a guitar so I decided to go for looks and worry about sound later. I was just playing around with scraps I had, so its a sandwich of woods. The front is Olivewood, the middle is ash and the back is (from outside to middle) Sapele, Ceylon Satinwood, Cocobolo and Ebony down the middle.

Hard to get pieces without checks and very heavy strong wood. I have these I have been holding onto and now having them made into handgun grips

Can I use olive tree wood to make a tobacco smoking pipe?

Is it safe or will it release harmful toxins?

Thanks!

A great way to avoid bitterness in spoons/bowls is to seal them with Carnauba wax. It creates a very nice finish, hard as epoxy, and the best part is that it melts at 130°C so you won’t melt it off in a hot soup. It is a vegetable wax used in cosmetics so it’s definitely food-safe.

When processed, the smell is more like a fruity perfume than the smell of wood. Fantastic bonus!

Does anyone know what color stain I could use to make pine look like Olive wood? We’re getting a table made out of olive(similar to pic), and having custom shelves made out of pine, and I would like the shelves to be match/compliment the table as much as possible. Thank you!

Of you have the shelves made of spalted sugar maple they will look similar

I built this Olive wood snare drum. Plays beautifully

I have heard that some olive wood pieces can be a lot clearer in color, nearing grayish-white, kind of similar color to white oak, is that true? I cannot seem to find confirmation anywhere on the techniques/treatment or conditions (older, dried, maybe?) required to give it that color… help please? ?

Absolutely. I have worked with olive wood a lot (I burn lots of it in my wood stove) and it can be from blonde to silvery to almost light golden white.

I am trying to figure out if this is olivewood

I can’t tell conclusively from those pictures, was this piece sold to you specifically as olive?

I got it at a garage sale and when I tried to identify it using google lens the only things that come up that as the same free form vase are olive wood. Thank you

I would say if going off an totally blank slate, I wouldn’t put olive as a first guess. It would be a remarkably large piece of solid olive wood, which technically isn’t impossible, but seems uncommon. I would need to see some clear, close up images of different parts of the grain to possibly tell more.

Beautiful!

Does anyone have experience gluing European olive wood?

We use Olive all the time. Great wood and if you like green olives, you’ll be smelling the fresh cut offs more than working it. One of my favorites. One drawback is I have found that typical finishes (poly etc) has big problems curing on it. The oils in the wood must be. I have tried eurethane, poly, and even shellac with no luck. My go to for a gloss finish on this is clear resin.

Try tung…it works great

Should I use olive for a guitar or bass body? It says it’s unstable but it’s twice as hard as say Ash.

In my country we use it mainly as firewood. Trunks, burl, branches…the whole thing!

Are you talking about acoustic or electric guitar? Since you compared it to ash, I’m going to assume it’s for a solid body electric. I suppose you could make it from olive, but I think it’d be a pretty heavy body. You might just be better off using a lighter weight wood for the body and then laminate a thinner (maybe bookmatched?) piece of olive for the top.

The Olive cutoffs in my previous post are from a large burl. I’m now working on the smallest of two bowls I will turn from it. Here’s the completed outside, sanded but with no finish. Turning it exposed many old fissures which I’m filling with CA glue.

Here are some Olive burl cutoffs, one resawn and one sanded with shellac sanding sealer. From a tree in California about 100 years old.

Hola

Vivo en España y el olivo es una parte fundamental de nuestra cultura como en todo el mediterraneo. Principalmente la madera de olivo se ultiliza para la fabricación de objetos de pequeño tamaño en general mediante talla, cucharas, tenedores, cajas de relojes, cajas de joyas, tablas de cortar para la cocina etc.

Os adjunto unos anillos fabricados por mi con esta madera

Soy un apasionado sobre todo del árbol y de su significado cultural.

Hi!!, would be possible the construction of a wood house only with olive tree wood?

It would be possible but olive lumber tends to be pretty short in length, very heavy, and that amount of olive wood would be VERY prohibitively expensive.

can you make welsh lovespoons from olive wood

I have carved a few spoons in Olive and it is a great wood. The only issue i have found it the wood has several species and they are not all the same. I like Bethlehem Olive (not sure of spelling) It also may have internal checks so I ger a spoon carved and I suddenly find a crack in the bowl area but this is fairly rare. It can be carved into a fairly thin bowl for a spoon.

Is burl olive veneer a good candidate to cerused?

no it is knot

Yes, puns aside, I agree. While I don’t have direct experience with the technique mentioned, it appears to basically be using a white pigment to color the growth rings of the wood. Olive has very small pores which would more than likely not receive the larger pigment particles. I would think something like elm or ash would be a much better choice when it comes to doing this to burls, since they are ring porous woods with a more open grain structure.

A local store in UK sells olive wood mortars & pestles. I use the mortars for re-turning as they are always chunky. I have a large supply of pestles waiting to be turned into something, maybe pens.

I have a large mortar. Can olive wood be used to make a pestle? Is it a strong/sturdy wood to use?

Regards

Raj

I turned one a few years ago and it still works fine. There is a bit of wear on the head but it’s been in use for a while now.

How would an olive branch work as a shovel handle? I have need of a handle for a special tool and the best analogy I can make for the stress it will be exposed to is a shovel handle. Since I have an otherwise perfectly sized and shaped olive branch, I’d just like to know if it will take the stress.

My guess is that it’d be plenty strong. Just keep in mind that a branch section will contain the center (pith) of the wood, and generally this central area is omitted from most wood products as it can be unstable or cause checking when drying.

May I ask what does checking when drying mean? Does it mean cracking from very uneven movement?

Thank you.

Yes

Thanks.

Olea capensis density can be 1500 kg per square meter.It the most dense wood in the world and at that density it probably beats all your otther hardest woods.

You should view this video where I talk about this exact instance of purported wood density. https://www.youtube.com/watch?v=IfXW9Tw-3O0

I’ve turned Italian and Holy Land Olivewood. Both feel, look and turn the same…like wooden butter. This yoyo and display is made from Italian Olive.

Sandra – I would love a branch or two if you are near myself or a relative. (CA, ID, UT). Thanks. Apparently nice for smaller items like utensils, handles, bowls. My intent, anyway. Popular for woodturning and apparently can be a tad pricey. Nice grain. (According to a late uncle.)

hi can i use afecan olive tree as firewood?

i have a dead one that im going to remove

What a shame to burn the wood. This wood is prized for spoon carving.

Very nice work Jack

Nice spoon. I have just acquired some olive wood from an orchard that is being torn out. I have started cutting out some spoon blanks (green wood) and I am wondering about drying first, or after carving. Also when and how to treat the wood after carving. Is it safe for use in the kitchen? I’d appreciate any comments you could provide.

Treat it with food safe oil or paste wax after sanding to a medium or fine grit (800 or 7000).

Do you know if those treatments will help with the bitterness of olive wood? I purchased some beautiful spoons from a craftsman but I can’t manage to use them to eat, due to the bitter taste of the wood and even the residual bitterness it leaves behind in the food while cooking with them. I want to use these spoons but they’re incredibly bitter. Any tips appreciated.

Nevermind, ya’ll! I found a solution: soaking the spoons in isopropyl alcohol 91% for 6 hours removed the bitterness almost completely. (Did some research on how they de-bitter olives and came up with the idea. I was curious to try Dupont AmberLite resin, but the smallest sample is $80 and I don’ know the process, so no.) I dried them and then finished with mineral oil. They’re good now. No bitterness.

IT does burn very well due to the oils in it but only burn what you can’t use as timber or craft as it is a very nice wood and perfect for bowls and spoons.

I have some planks of olive wood (the south African species of Olea

capensis, but I find it extremely difficult to plane because the wood

tends to chip ( form scallops) along the grain no matter which direction

I plane. This is due to the irregular grain. I am using a

planer/thickneser with normal steel blades. I would like to hear from

someone how I can get by this problem. I attach a photo.

Looks like that piece of Olive has a fair amount of curl to it. Here’s some tips to help reduce tearout:

-Make sure blades are sharp (obvious…)

-Take very light passes

-Lightly moisten surface of wood to soften fibers before planing (never tried it before, but it sounds like it’d be worth a shot)

-Retrofit your planer with a spiral cutter-head, such as a Byrd Shelix type with carbide inserts

-Use a thickness sander instead (I have the Performax 16-32, and these machines are worth every penny IMO!)

One other thing I would add is to make sure the wood is dry. I have the same problem when carving, if the wood is still wet, it is more difficult to carve.

I’d suggest planing with a drum sander in this case. Take multiple small passes (1/32″) It’ll take time, but it’ll be well worth it when your done. You can use a drum sander at a high school wood shop perhaps, or make your own out of some old treadmill parts! YouTube can teach you how to do that.

Looks like that piece of Olive has a fair amount of curl to it. Here’s some tips to help reduce tearout:

-Make sure blades are sharp (obvious…)

-Take very light passes

-Lightly moisten surface of wood to soften fibers before planing (never tried it before, but it sounds like it’d be worth a shot)

-Retrofit your planer with a spiral cutter-head, such as a Byrd Shelix type with carbide inserts

-Use a thickness sander instead (I have the Performax 16-32, and these machines are worth every penny IMO!)

I have some planks of olive wood (the south African species of Olea capensis, but I find it extremely difficult to plane because the wood tends to chip ( form scallops) along the grain no matter which direction I plane. This is due to the irregular grain. I am using a planer/thickneser with normal steel blades. I would like to hear from someone how I can get by this problem. I attach a photo.