Common Name(s): Lignum vitae, palo santo, guayacan, holywood, genuine lignum vitae

Scientific Name: Guaiacum officinale and G. sanctum

Distribution: Central America and northern South America

Tree Size: 20–30 ft (6–10 m) tall,

1–2 ft (.3–.6 m) trunk diameter

Average Dried Weight:AVERAGE DRIED WEIGHT

Density is the measurement of a wood’s weight per unit volume. Here, "dried weight" specifically refers to wood at 12% moisture content, and values are given in pounds per cubic foot and kilograms per cubic meter. Also keep in mind that density commonly varies by +/- 10% from the average.

Click on the link "Average Dried Weight" for more details. 78.5 lbs/ft3 (1,260 kg/m3) Extremely High WEIGHT TIERS

Extremely Low: 0+ kg/m3

Very Low: 420+ kg/m3

Low: 520+ kg/m3

Medium-Low: 620+ kg/m3

Medium: 730+ kg/m3

Medium-High: 840+ kg/m3

High: 960+ kg/m3

Very High: 1,080+ kg/m3

Extremely High: 1,200+ kg/m3

Tiers are based on CSIRO provisional strength groupings (SD1-SD8) based on density.

Janka Hardness:JANKA HARDNESS

This test measures a wood’s resistance to indentation, and is the pounds of force (or Newtons) required to embed a .444" (11.28 mm) diameter steel ball halfway into the wood. Values are for side grain, measured at 12% MC.

Click on the link "Janka Hardness" for more details. 4,390 lbf (19,510 N) Extremely High JANKA HARDNESS TIERS

Extremely Low: 0+ N

Very Low: 2,050+ N

Low: 3,150+ N

Medium-Low: 4,480+ N

Medium: 6,280+ N

Medium-High: 8,380+ N

High: 11,080+ N

Very High: 14,000+ N

Extremely High: 17,450+ N

Tiers are derived from CSIRO provisional strength classifications (SD1-SD8) in conjunction with the USDA's estimated hardness based on density.

Modulus of Rupture:MODULUS OF RUPTURE

Sometimes called bending strength, this test measures a wood’s strength before breaking (i.e., rupturing). Values are given in pounds of force per square inch and megapascals, measured at 12% MC.

Click on the link "Modulus of Rupture" for more details. 17,970 lbf/in2 (123.9 MPa) High MOR TIERS

Extremely Low: 0+ MPa

Very Low: 45+ MPa

Low: 55+ MPa

Medium-Low: 65+ MPa

Medium: 78+ MPa

Medium-High: 94+ MPa

High: 110+ MPa

Very High: 130+ MPa

Extremely High: 150+ MPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Elastic Modulus:MODULUS OF ELASTICITY

This test measures the wood’s level of deformation when under a given load. Higher values indicate less deformation (i.e., stiffer). Values are given in pounds of force per square inch and gigapascals, measured at 12% MC.

Click on the link "Elastic Modulus" for more details. 2,481,000 lbf/in2 (17.11 GPa) High MOE TIERS

Extremely Low: 0+ GPa

Very Low: 7.9+ GPa

Low: 9.1+ GPa

Medium-Low: 10.5+ GPa

Medium: 12.5+ GPa

Medium-High: 14.0+ GPa

High: 16.0+ GPa

Very High: 18.5+ GPa

Extremely High: 21.5+ GPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Crushing Strength:CRUSHING STRENGTH

Also called compression strength, this test measures the maximum stress sustained before failure. Force is applied parallel to the grain (producing stress akin to chair legs). Values are given in pounds of force per square inch and megapascals, measured at 12% MC.

Click on the link "Crushing Strength" for more details. 12,380 lbf/in2 (85.4 MPa) Extremely High CRUSHING STRENGTH TIERS

Extremely Low: 0+ MPa

Very Low: 30+ MPa

Low: 36+ MPa

Medium-Low: 41+ MPa

Medium: 47+ MPa

Medium-High: 54+ MPa

High: 61+ MPa

Very High: 70+ MPa

Extremely High: 80+ MPa

Tiers are based on CSIRO strength classifications (SD1-SD8).

Shrinkage:SHRINKAGE

These values represent the percentage change in radial and tangential faces of the wood—as well as the total (volumetric) shrinkage—as the moisture content goes from green (maximum) down to oven-dry (minimum), approximating the wood's stability with changes in humidity. T/R ratio helps to estimate the uniformity of the shrinkage across different wood faces.

Click on the link "Shrinkage" for more details. Radial: 5.3%, Tangential: 8.7% Very High SHRINKAGE TIERS

Very Low: 0%+

Low: 3.6%+

Medium: 5.1%+

High: 6.6%+

Very High: 8.1%+

Tiers are based on tangential shrinkage (green to oven-dry) from CSIRO shrinkage classifications (1-5).

Volumetric: 14.0%, T/R Ratio: 1.6

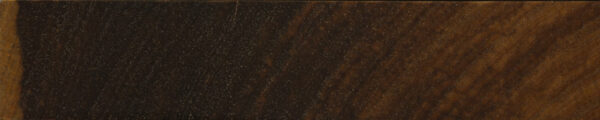

Color/Appearance: Heartwood color can range from olive to dark green/brown to nearly black, sometimes with a reddish hue. The color tends to darken with age, especially upon exposure to light. On average, the heartwood color of genuine lignum vitae tends to be darker than that of Argentine lignum vitae or verawood in the Plectrocarpa genus.

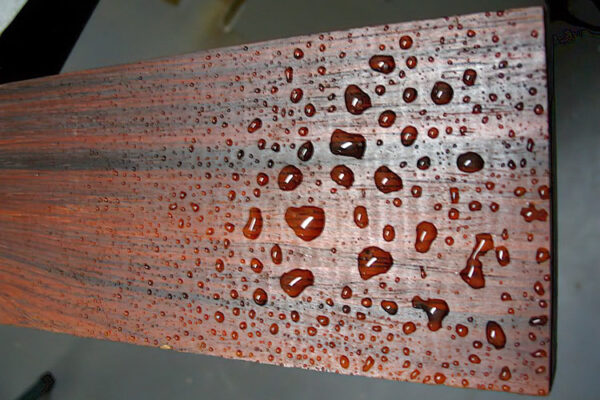

Grain/Texture: Grain is interlocked, sometimes severely so. Has a very fine texture and can be polished to a high luster due to its high natural oil content. Raw wood surfaces can feel greasy or oily to the touch.

Rot Resistance: Lignum vitae is reported to be very durable for outdoor use and is also very resistant to insect attack.

Workability: Lignum vitae has a tendency to skip over-top jointer cutters on account of its extremely high density, and very light passes are recommended. Lignum vitae will also dull cutters, and overall the wood is considered quite difficult to work. Also, due to its high oil content, it’s very difficult to get strong and reliable glue joints. Finishing can also be problematic as well. However, lignum vitae turns well on a lathe.

Odor: Lignum vitae has a mild, perfume-like fragrance. (Though its scent isn’t quite as pungent nor as lingering as the closely-related commercial woods in the Plectrocarpus genus.)

Allergies/Toxicity: Lignum vitae has been reported to cause skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Trade of lignum vitae is restricted (see sustainability section below), and prices for genuine lignum vitae are accordingly very high (and usually from questionable sources). Irregular chunks and turning blocks are sometimes sold by the pound instead of the more common board-foot measurement.

Sustainability: This wood species is in CITES Appendix II, and is on the IUCN Red List. It is listed as endangered because populations are severely reduced and exploitation for both its wood and resin extracts have continued for hundreds of years.[1]Barstow, M. 2019. Guaiacum officinale. The IUCN Red List of Threatened Species 2019: e.T33701A68085935. https://dx.doi.org/10.2305/IUCN.UK.2019-1.RLTS.T33701A68085935.en Accessed on 25 … Continue reading

Common Uses: Tool handles, mallet heads, bearings, bushings, pulley wheels, and turned objects.

Comments: The common name lignum vitae is Latin for “wood of life,” which is derived from the tree’s many medicinal uses. Lignum vitae has been imported into Europe for medical use since 1508, and its use became so highly demanded that “the wood sold for as much as seven gold crowns a pound.”[2]Record, S. J., & Hess, R. W. (1949). Timbers of the new world (p. 556).

Unfortunately, lignum vitae has been exploited to the brink of extinction, and is now an endangered species. While lignum vitae was among the very first species to be listed as endangered by CITES back in 1975, even the closely related Argentine lignum vitae (Plectrocarpa sarmientoi) eventually received protected status some 30 years later.[3]Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES). (2007). Notification to the Parties No. 2007/040: Inclusion of Bulnesia sarmientoi in Appendix III. CITES … Continue reading

Regarded as one of the heaviest and hardest woods in the world. Its durability in submerged or ground-contact applications is legendary—it has been used for propeller shaft bearings on ships, and its natural oils provide self-lubrication that gives the wood excellent wear resistance.

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Salem Barker for providing the sculpture photos of this wood species.

Identification: See the article on Hardwood Anatomy for definitions of end grain features.

Parenchyma:PARENCHYMA

Describes the pattern(s) of the parenchyma cells seen on the endgrain, such as vasicentric, aliform (winged or lozenge), confluent, and banded.

Click on the link “Parenchyma” for more details. diffuse-in-aggregates, vasicentric

Rays:RAYS

Describes the relative width and frequency of the rays (appearing as thin vertical lines on the endgrain), as well as a note on if these rays are visible with/without magnification.

Click on the link “Rays” for more details. narrow width, close spacing; rays not visible without magnification

Lookalikes/Substitutes: Often confused with Plectrocarpa spp. such as verawood and Argentine lignum vitae. The two genera can be separated by pore arrangement. Plectrocarpa spp. have pores arranged in radial or diagonal rows, while Guaiacum spp. pores are exclusively solitary and occur in a more or less random distribution.

Notes: Scent in Plectrocarpa species tends to be stronger and lingers longer in comparison to Guaiacum. For a more in-depth comparison, please see the article How to Tell Genuine Lignum Vitae from Argentine Lignum Vitae.

(Species)

(Authority)

Related Species:

Related Content:

References[+]

| ↑1 | Barstow, M. 2019. Guaiacum officinale. The IUCN Red List of Threatened Species 2019: e.T33701A68085935. https://dx.doi.org/10.2305/IUCN.UK.2019-1.RLTS.T33701A68085935.en Accessed on 25 February 2025. |

|---|---|

| ↑2 | Record, S. J., & Hess, R. W. (1949). Timbers of the new world (p. 556). |

| ↑3 | Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES). (2007). Notification to the Parties No. 2007/040: Inclusion of Bulnesia sarmientoi in Appendix III. CITES Secretariat. https://cites.org/sites/default/files/eng/notif/2007/E040.pdf |

I just wanted to say thanks for this site. I also own the book which I actually use more than the site but when I am away from my shop and someone says “what kind of wood is that?” I can pull out my phone and ID right there on the spot.

Hello,

Is this product lignum vitae?

Lignum vitae slab painted with shellac

Hi, I am from Sri Lanka . I have few fully grown trees and young nursery which I maintained. In Sri Lanka no of plants are very limited and many do not know the value of this plant. I follow your information flow of this plant which is very informative. Thank you

Interesting to see such interest in this incredible useful material. I work with genuine guaiacum every day and find it is very difficult to discern between the Guaiacum Officialle, Sanctum, and Coulteri. Argentine AKA fake lignum vitae has an acrid, not pleasant smell while genuine has a sweet fragrance.

My Dad just gave me this small piece of wood yesterday. He said it was gifted to him from a blade smith friend of his, some 30+ years ago. At first, my Dad called it Ironwood, then later he recalled his friend saying it was lignum vitae. The two smaller pieces are cut from the same larger piece. I’m currently making a nut and saddle for the acoustic guitar being used as a background for these pictures. I am curious to know if this is indeed lignum vitae or whichever species it may be. In any case it is quite… Read more »

Can’t see enough endgrain detail to tell which it might be. Superficially it does look more like the Argentine type to me. https://www.wood-database.com/how-to-tell-genuine-lignum-vitae-from-argentine-lignum-vitae/

Hi Eric. Thank you for your reply. I had a hard time taking a decent picture this morning. I’m a little on the shaky side. Too much coffee, perhaps. I hope this picture helps a little more.

Sorry, still no good. It looks like there’s a lot of compression on the image, which usually happens if you take a pic with a phone in poor lighting. I recommend trying it again in full sunlight, it will give less noise and a faster shutter speed for clearer results.

hi, I hace several tablets of guaiacum but i can’t identify which guaiacum It is.

Could you tell me which guaiacum It is?

?thanks.

Did these all come from the same tree? Are you sure they are all Guaiacum species and you are trying to figure out which species, or are you trying to see if they are Guaiacum versus Bulnesia genus? To me, the herringbone type pattern on the quartersawn portions in your third picture looks more like Bulnesia spp.

Exactly, I want to know if they are guaiacum or bulnesia.

The man who gave them to me called it guaiacum. He said he got the trunks from a warehouse in northern Spain where they had been kept for more than 60 years. I suppose that all the boards are from the same type of tree. I post more pictures.

Thank you very much for the information, I look at the web frequently. Excellent work.

Based on color and pattern, my best guess at the moment is Bulnesia. It should be fairly straightforward to tell them apart if you get a good enough view of the endgrain. Right now, the endgrain surface is still too rough and the picture is too far away to see enough detail to tell them apart.

Perhaps these photographs show it better.

Thank you very much

Thanks, mostly the same opinion as before. Leaning heavily toward Bulnesia spp. but would need to see endgrain to be sure.

thank you share this information online. I am a whistle lover from China, last week my tin whistle was broken, it was made of african blackwood according to seller’ statement. But a friend i met recently, who is a expert to make irish tin whistle, told me this was not blackwood. So I start to make some research online, i found out wood classes are so many and complicated. There are so many names, and fancy names on market. I am planning to make a whistle with arginine lignum vitae, beacese its dense and hardnest. But in chinese market i… Read more »

That is correct. Verawood is Argentine lignum vitae

Hi Eric, great website. Do you think this is lignum vitae sapwood? It is very orange/yellow in planed specimen and with rich lemon yellow sawdust. It sinks in seawater. The pencil marks on the image are 100 mm apart. The pore pattern suggests not verawood but it is LV? Strangely, this plank of approx 5000x200x75 mm was found on a beach here in SW Ireland, well away from a road. Very heavy plank! How did it get there?! Thanks for your help.

Thanks for the good endgrain picture. Both verawood and lignum vitae have pretty distinct grain patterns, and I can say pretty conclusively that this is neither of those woods. Unfortunately, the pore pattern is very standard looking for a tropical hardwood — that is, large pore in a diffuse porous arrangement. Though the fact that it sinks in water is a pretty good clue — are you sure it’s throughly dried yet, or do you know the moisture content? Perhaps a picture or two of the face grain might help too.

Eric, I have attached two face grain pictures. I’m sure that it is dry and it sinks quickly in seawater. Would appreciate your view and thanks for your help.

Sorry, I noticed a pretty critical omission in my previous post, I meant to say that I can tell conclusively that it is “NEITHER” of those two woods. Is there any noticeable scent when working with the wood?

Kinda’ looks like silver wattle. If you have any extra cuts, I’d send a piece of it to USDA for confirmation.

A German lab that does CITES analysis indentified it – Greenheart. Thank you all for your interest.

Lignum vitae is also native to Southern Florida, found in The Keys. My father grows it.

Hello, do you think this tree is the original lignum vitae?Or argentina lignum vitae ? Help me pls :)

Generally the more reddish color would be more indicative of genuine lignum vitae, but that’s by no means a conclusive way to differentiate the two. I can’t see enough of the endgrain through the wax to make out the pore structure. Ideally, I’d need to see a raw wood surface of the endgrain in a close up shot to tell them apart.

I have found that Lignum can be worked very easily with sharp tools. It is basically self lubricating due to the high oil content. When using a rotary carver with a carbide burr it carves very much like HDPE plastic. I got some nice pieces that were salvaged after sitting on the forest floor for several decades.

Interesting to see so much information on this wood type. In 1996 I was working onboard the legendary cruise ship SS Norway ( former SS France), and we went to drydock in Southampton. Among all the jobs done, we also changed propeller shafts, and the propeller shaft casing bushings. The bushing in the shaft casing and propeller brackets was made of Lignum Vitae, laid in a circle in more than a meter in length in the bracket and shaft casing. I took a few pieces of the new materials, and one of the used ones that I have on display… Read more »

I have a piece of LV to make mallets for carving. What is the mass of a block of LV? I’m planning to turn the wood with a friend who has more skills than me.

Any suggestions for dimensions for a predictable mallet head?

I’m thinking of preserving the block to make just the heads and make handles of another hard wood. Suggestions?

I have some pieces around here, this wood don’t float on water, super heavy wood

That’s the real deal. Favorite wood and smell on earth.

The smell of fresh cut Lignum Vitae is a breath of fresh air. Even better than pine-sol.

My cricket fan friend tells me that Lignum Vitae is (or maybe was) used to make cricket bails to be used in windy weather. If they still fall off the umpire can choose to play on without bails, and must decide if a hit constitutes a broken wicket or not.

I am a flutemake/fluteplayer from Connemara Ireland. I got a lovely piece of Lignum Vitae from a musician friend from Belgium and I wish to find out whether or this timber is suitable for making traditional Irish flutes, keeping in mind that the flute would be left in on your face when playing.

Marcus Hernon

This wood is used for rudder bearing material in the U.S.S. Constitution.

As a young man, my Father worked for an Uncle in His SAW MILL. The SAWYER used lignum Vitae to make the Bearings for the Big Saw. Never had to lubricate because of the natural oils. At one time they tell me it was used as spacers in the cores of Electrical Transformers. Would be submerged in oil.

I have a guitar with a nearly black Lignum Vitae fretboard and it’s the best I’ve ever played

loool, For sure that ain’t lignum vitae. It’s probably Ebony. Can you proof it’s L.V.? I don’t think so.Give the model number and I’m sure the specs will not say Lignum Vitae fretboard.

Density. If it is as you say, you’ll need to prove it. Don’t let it out of your sight.

That’s Gorgeous

I have been turning old bowling balls into potpourri bowls brilliant to work with

I have two bowls my father made from a lignum vitae bowling ball, in 1944. Have been stored in a barn for 75 years, good as the day he made them!

My favorite wood-carving mallet is made of Lignum Vitae. I love the feel of it the weight and balance of it is perfect for what I do. When I bought it 40 years ago I was told to put it in water occassionally to keep it in good shape but I never did, and it’s fine the way it is.

Worked with Lignum vitae at Chatham Dockyard on warship propellor thrust blocks / bearings.I believe policeman’s truncheons were once made of it. , also seem to remember staying at a chain hotel (Amadeus ) ? at two locations where a piece of Lignum vitae was used as a bar floor feature.Would not have thought too many guests would have known what they were looking at.

This wood was used as rail road ties here in Costa Rica.

Hand cut with an axe.

The better it was cut the more the rail company paid.

My 85 year old neighbor and friend still has the axes he used to cut ties with.

I will sail to costa rice to remove these railroad ties lol

What are the axe handles made from?

I LOVE this material for making tools in restoring silver because of its density and tight grain. I put a 1200-grit finish on the wood ends and use them to remove dents in trays because it doesn’t stretch silver the way steel does.

I picked up about 40 pieces that are 18inch x 3×3. Rough sawed it was shipping material marked product of India this is a project just sanded no finish

Is the oil in this wood foodsafe for cutting boards?

The dust of this wood is considered toxic with exposure to skin over time can cause dermatitis. Here is a link to woods and their toxicity and effects. https://library.davidtilson.com/materials/toxic.html

Wood has been banned by many countries for food blocks because bacteria has been found to survive in the cracks and knife scores even after submergence cleaning. White plastic is the alternative.

The prohibition against wood cutting blocks is largely overzealous instructions from insurance companies. Using a slightly softer wood and recommending to buyers that they regularly scrape the wood surface and scrub with salt is the tried and tested way to keep cutting blocks food safe.

Better off with Sycamore for cutting boards, its self sterilising.

I have a 2x2x8 inch pices of this wood it was given to me from a friend. I make tobacco pipes, I’m concerned about the the fumes or gas that could occurre from the natural oils in wood when the tobacco is burning in the smoking chamber. Would anyone know if this wood has ever been used for a Tobacco Pipe. Or if this wood was used in food or water containers application.

In Paraguay they use it for cups for their national drink called Tereré. Google it, you’ll see. They call it Palo Santo there.

My father has a load of it in his shed from the 1970’s. Every now and again he will make a pan handle out of a bit. I had not idea it was so sought after.

Lignum Vitae is also used in leather working, specifically polishing the edges of straps and belts.

During the ’70’s I owned a Star class sailboat #2112. The skeg and rudder were made of

Lignum Vitae which was unpainted and had a 2″ split at the top of the rudder. I tried to repair the split and was unsuccessful. The boat was built in Chicago in 1942. Frames were white oak. The garboard planks were mahogany. The rest of the planking was white cedar. Each side was a single plank 30″ wide, 24′ long and 2″ thick. Not a blemish in either one. I doubt

that one could find wood like this today.

I’ve been looking for a naturally green wood for a custom butcher block. After much research this is the one that’s come up the most. Any pictures I’ve seen have been a darker colour (not green). Does anyone have any experience with Lignum Vitae? What would you recommend be done in order to have the wood turn green? (expose to sunlight? etc)

JC, first off, I’d just use Argentine Lignum Vitae, listed as “Verawood” on this site. It’s easier to obtain, costs less, and the color tends to be greener (in my experience anyway).

Secondly, the color change seems to be facilitated with no finish on the wood. Usually butcher blocks have minimal finishing as it is, so you should be okay here. I’d be interested to see if mineral oil would even penetrate a wood as oily as Lignum.

Thanks for the info, very helpful.

True Lignum Vitae will still turn green even after you put polish on it. (if you can get it to stick to it) I have made a few rings out of it and finished it with CA glue, but it really didn’t need it as it can be sanded to a high shine. If you want to get good at sharpening your tools work with this stuff…..

My verawood matches your picture, it is nothing like lignum vitae in my experience. It was sold to me as lignum vitae; a hard lesson.

Are you referring to the overall color of the wood, or the endgrain and the pore arrangement? Colors can be highly variable, so the best way to tell them apart is by looking at the endgrain. https://www.wood-database.com/wood-articles/how-to-tell-genuine-lignum-vitae-from-argentine-lignum-vitae/

It is very easy to tell them apart. The Verawood endgrain runs mirror like through the whole piece.

I am an apprentice saddle maker in the U.S. and just received some tools

from a master saddler, David Boot from England. Some of the tools are

made from lignum vitae, including a masher and loop blocks. Both of the

types of tools are meant for extreme force, and are not only extremely

strong, but they are equally as beautiful.

I have a supported spindle with lignum on the tip and an insert in the support bowl. It spins really well and for a long time. It helps the tip NOT to become blunt and slow down.

I am an apprentice saddle maker in the U.S. and just received some tools from a master saddler, David Boot from England. Some of the tools are made from lignum vitae, including a masher and loop blocks. Both of the types of tools are meant for extreme force, and are not only extremely strong, but they are equally as beautiful.

I have a set of crown green bowls made from lignum vitae. Far better to play with than the more widely used plastic varieties.

I’m right in the middle of fashioning a set of 4-1/2 x 7 inch lignum vitae bearings for a 1200 lb flywheel. It is a bit rough on tools, but it sure is pretty, polished stuff just the way it comes off the saw. I have a picture of the bearings being constructed at

I see a great deal of sapwood. Is it as durable as the heart?

Some older hydro-turbines used journal bearings made made from this material – for the same reasons as ship’s propellers. I’ve also understand that the block and tackle equipment in many older ships had bearings of Lignum Vitae. Cool stuff!

I had a mate that worked on the Queen mary he was the 34 officer & his job was to watch the main bearing on the prop shaft & put water on when needed the bearing was Lignum Vitae

I have a Lignum Vitae cane that was given to my Great Grandfather at the opening of the Panama canal, this wood was apparently used in the construction of the canal.

late father had set of highland bagpipes made from this wood in 1925 by a maker in otago n.z. wood came from propeller bearings in old ship. beautifull soft mellow sound commented on by several piping judges over the years.