DATA SOURCE(S): 1,8,14,30,36,43,54

Common Name(s): Ipe, lapacho, Brazilian walnut

Scientific Name: Handroanthus serratifolius, along with H. impetiginosus, and several other lesser-used commercial Handroanthus species; all formerly of the Tabebuia genus

Distribution: Tropical Central and South America (Brazil accounts for over 90% of exports by volume)[1]CITES. (2022). Nineteenth meeting of the Conference of the Parties. Proposal 44.

Tree Size: 100-130 ft (30-40 m) tall,

2-4 ft (.6-1.2 m) trunk diameter

Average Dried Weight: 65.5 lbs/ft3 (1,050 kg/m3)

Specific Gravity (Basic, 12% MC): 0.91, 1.05

Janka Hardness: 3,490 lbf (15,520 N)

Modulus of Rupture: 25,740 lbf/in2 (177.5 MPa)

Elastic Modulus: 3,089,000 lbf/in2 (21.30 GPa)

Crushing Strength: 13,160 lbf/in2 (90.7 MPa)

Shrinkage: Radial: 5.5%, Tangential: 7.1%,

Volumetric: 12.4%, T/R Ratio: 1.3

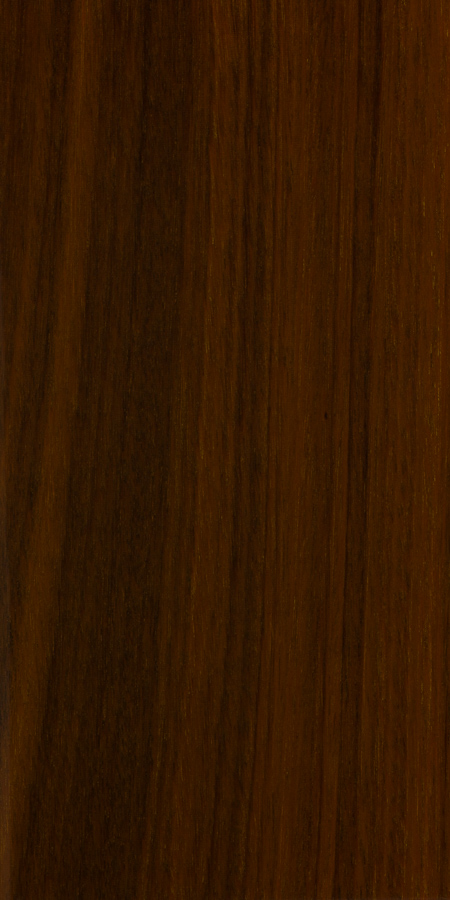

Color/Appearance: Heartwood can vary in color from reddish brown, to a more yellowish olive brown or darker blackish brown; sometimes with contrasting darker brown/black stripes. Ipe’s appearance can be very similar to cumaru (Dipteryx odorata).

Grain/Texture: Has a fine to medium texture, with the grain varying from straight to irregular or interlocked. Moderate natural luster.

Rot Resistance: Rated as very durable; with excellent insect resistance, though H. serratifolius is susceptible to marine borers.[2]Berni, C. A., Bolza, E., & Christensen, F. J. (1979). South American timbers-the characteristics, properties and uses of 190 species. (p. 210). Superb weathering characteristics. (Ipe was used for the boardwalk along the beach of New York City’s Coney Island, and was said to have lasted 25 years before it needed to be replaced—an amazing lifespan given the amount of traffic and environmental stresses put upon the wood.)[3]Berger, J. (2011). A Fight Over Keeping Boards in the Boardwalk. The New York Times.

Workability: Overall, ipe is a difficult wood to work, being extremely hard and dense, with high cutting resistance during sawing. Ipe also has a pronounced blunting effect on cutting edges. The wood generally planes smoothly, but the grain can tearout on interlocked areas. Also, ipe can be difficult to glue properly, and surface preparation prior to gluing is recommended. Straight-grained wood turns well, though the natural powdery yellow deposits (called lapachol) can sometimes interfere with polishing or finishing the wood.

Odor: Ipe has a mild scent while being worked.

Allergies/Toxicity: Ipe contains lapachol (and related substances like lapachenole and deoxylapachol), which have been observed to produce pronounced irritant responses on skin.[4]Schulz, K. H., Garbe, I., Hausen, B. M., & Simatupang, M. H. (1977). The sensitizing capacity of naturally occurring quinones. Experimental studies in guinea pigs. I. Naphthoquinones and related … Continue reading Although severe reactions are quite uncommon, ipe has been reported to cause skin, eye, and respiratory irritation, as well as other effects such as headaches, asthma-like symptoms,[5]Algranti, E., Mendonça, E. M., Ali, S. A., Kokron, C. M., & Raile, V. (2005). Occupational asthma caused by Ipe (Tabebuia spp) dust. Journal of investigational allergology & clinical … Continue reading and/or disturbance of vision. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Primarily sold as decking or flooring, individual boards for furniture or general use are sometimes available as well. Prices are in the medium range for an imported tropical species. Though with ipe’s 2024 listing in the CITES Appendix II, availability is expected to steadily diminish, and prices to increase.

Sustainability: Ipe is listed in the CITES Appendix II under a blanket restriction spanning multiple genera (including Handroanthus, Tabebuia, and Roseodendron). Handroanthus serratifolius is also on the IUCN Red List of Threatened Species. It is listed as endangered due to a projected population reduction of over 50% in the next 100 years, caused by a decline in its natural range, and exploitation. (A crucial distinction should be pointed out, because this assessment is based upon projected population levels within 100 years in the future, rather than the more common method based on observed or inferred actual population decline in the past.)

But regardless of the real or perceived immediacy of any threats to Handroanthus, these tree species tend to grow in very low densities, with mature trees only occurring once per 300,000 to 1,000,000 square feet (3 to 10 hectares) of forest area. This necessitates the clearing of large sections of rainforest trees, most of which, after factoring in the cost of transportation, have little to no commercial value.[6]Hutton, J. (2013). A Trail of Stumps. Landscape Architecture Magazine, 103(5), 117-126.

Common Uses: Flooring, decking, exterior lumber, veneer, tool handles, and other turned objects.

Comments: Ipe is a wood of extremes: extremely dense and durable, as well as extremely difficult to work. Its incredible hardness and strength make it well suited for flooring applications, though it’s usually referred to by the halo name ‘Brazilian walnut’ among flooring dealers—though it’s not related to true walnut in the Juglans genus. Because ipe is so difficult to work (both in shaping and surfacing, but also in gluing and finishing), it’s common to see the wood used mainly in unjoined, single-piece applications (e.g., decking planks) where mechanical fasteners can be used.

Formerly placed in the Tabebuia genus, species of ipe (H. guayacan, H. impetiginosus, H. serratifolius) were moved to the Handroanthus genus in 2007 based on genetic studies.[7]Grose, S. O., & Olmstead, R. G. (2007). Evolution of a charismatic neotropical clade: Molecular phylogeny of Tabebuia sl, Crescentieae, and allied genera (Bignoniaceae). Systematic … Continue reading

While Brazil exports the majority of commercial ipe, other regions also have Handroanthus species yielding similar lumber, though they are less commonly exported. When used locally, Handroanthus and Tabebuia trees are very highly regarded (several are included as national trees in their native habitat, including the nations of Paraguay, Venezula, and El Salvador). In this context, they are usually distinguished by the color of their very dramatic and widespread trumpet-like flowers, and are sometimes referred to as trumpet trees. Common flower colors include yellow (H. serratifolius and H. guayacan) and pink (H. impetiginosus and H. heptaphyllus).

Images: Drag the slider up/down to toggle between raw and finished wood.

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; growth rings not visible

Arrangement: solitary and radial multiples

Vessels: medium to large, few to moderately numerous; tyloses and other colored mineral deposits common

Parenchyma: visible parenchyma is usually minimal, but can be unilateral, winged, and marginal

Rays: narrow, normal spacing; rays not visible without magnification

Lookalikes/Substitutes: Cumaru (Dipteryx odorata), is another dense South American timber with very similar appearance and anatomy. However, cumaru tends to be slightly lighter in color, and has a characteristic vanilla/cinnamon scent while being worked (in contrast, ipe tends to have a more resinous odor).

Notes: None.

Related Content:

References[+]

| ↑1 | CITES. (2022). Nineteenth meeting of the Conference of the Parties. Proposal 44. |

|---|---|

| ↑2 | Berni, C. A., Bolza, E., & Christensen, F. J. (1979). South American timbers-the characteristics, properties and uses of 190 species. (p. 210). |

| ↑3 | Berger, J. (2011). A Fight Over Keeping Boards in the Boardwalk. The New York Times. |

| ↑4 | Schulz, K. H., Garbe, I., Hausen, B. M., & Simatupang, M. H. (1977). The sensitizing capacity of naturally occurring quinones. Experimental studies in guinea pigs. I. Naphthoquinones and related compounds. Archiv fur dermatologische Forschung, 258(1), 41–52. |

| ↑5 | Algranti, E., Mendonça, E. M., Ali, S. A., Kokron, C. M., & Raile, V. (2005). Occupational asthma caused by Ipe (Tabebuia spp) dust. Journal of investigational allergology & clinical immunology, 15(1), 81–83. |

| ↑6 | Hutton, J. (2013). A Trail of Stumps. Landscape Architecture Magazine, 103(5), 117-126. |

| ↑7 | Grose, S. O., & Olmstead, R. G. (2007). Evolution of a charismatic neotropical clade: Molecular phylogeny of Tabebuia sl, Crescentieae, and allied genera (Bignoniaceae). Systematic Botany, 32(3), 650-659. |

Hi, I am trying to identify some wood. This is Brazilian wood from the dining room table I had in my house as a kid. I am hoping to use it for guitar building projects, but am now starting to think it’s Ipe which seems to not work. It’s extremely heavy, but I haven not tried to cut it. Another possibility it Jatoba.

I am attaching photos.

Fun Half-Fact, freshly cut Ipe smells a bit like Beef Jerky… I’m not joking, it’s very odd…

We liked the original color of our Ipe wood deck so applied Linseed oil to protect it. Over the winter, some of the deck turned grayish and some of the more protected areas retained the preferred reddish color. What can we use to return the grey color to the original reddish color?

Does anyone have any experience with accelerating the aging process of Ipe? We are installing an Ipe fence and the client wants to see what it will look like once it ages.

Rubio monocoat and woca have decking and aging products

Can ipe’ be used for cutting boards ? I was given a little over 6bf and I don’t know what to do with it.

Yes, it does fine. I recommend wipin the parts you glue with rubbing sñchohol before glueing

I rehabbed a pt framed deck that was cedar decked. It lasted as expected, about 15 years. The pt frame was in solid condition. It was redecked with IPE in 2009 using all stainless steel screws and hidden clips. Fifteen years later, with several pressure cleanings and restaining, it looks as good as the day I installed it. I recently uncovered a scrap piece from the redecking that was buried for those 15 years. It was washed off and looked as good as new. The extra installation work was worth it. Use a high quality carbide blade, high quality stainless… Read more »

I came into possession of six 15x20x4M beams of old ipê, at least 20 years old, once used as a provisional staircase in my current home. Other than a bit of dry rot on the outside, some nail holes and some grain separation in several pieces, they’re almost perfect.

It is extremely difficult to cut and will destroy cheap sawblades; I also recommend a good dust-collection system if you’re going to be working with this.

Ok, it’s more than a mild scent when being worked. Imagine sitting around a tire fire downwind from a hog farm. And the scent sticks in your nose for days.

Which species are susceptible?

Rot Resistance: Rated as very durable; excellent insect resistance, though some species are susceptible to marine borers.

Here’s the top of the chair on the left with the checked pattern; on the right is what the other 3 chairs look like.

Hi

Can you recommend a good oil to protect this wood?

Ipe Oil works very well on ipe. Clean the wood and let it heat up in the sun. Apply the oil.

For outdoor furniture in NC two coats a year protects the wood nicely.

I have scrap end pieces from sawed off end pieces 2″ x 5 that I bought as ipe. 3 years later I just put it in my aquarium and it floats. Was I given something that was not ipe? I believe it did not float when I bought it.

Just because it floats doesn’t necessarily mean it’s not ipe. The density range can easily be within +/- 10% of average, and even more so if stored in conditions above or below average relative humidity which would cause EMC to be +/- 12% moisture content. Maybe try floating the wood on the top of the water for a few days and see if eventually sinks.

Thank you Eric for replying to my question. I put in several samples that have been out of the rain for a couple of years in my aquarium. Some floated, some sank, all sank eventually. I live out in the country so I had to buy online. Thank you for reassuring me.

Steve

Can someone help me identify what species these are? I bought both pieces as Ipe (lapacho) but the piece on the left, the browner one, is firmer, has absolutely no smell (even when processed) and feels “greasy” to the touch. The piece on the right is a little softer, has more fine pores, is distinctly greenish and has a very distinct smell, in my opinion unpleasant; it definitely doesn’t smell like vanilla or cinnamon like Cumaru…

Looks like Ipe and Teak

Can anyone help me identify the wood species in this photo. It was an old table top.

It’s very hard and strong which is why I thought it might be ipe but not sure. I wet the top half of the piece to better bring out the color tones.

Any thoughts are appreciated.

Do you have any pictures of the endgrain? It doesn’t look like ipe to me. The wavy jagged patterns in the flatsawn “cathedral” portions of the grain remind me of elm, but that’s just a guess.

I’ve been working with hundreds of pieces scrap ipe from my deck for the past year. I’m almost certain that what you have here is not ipe. Ipe has a wide range of coloration and graining, but I haven’t seen anything that looks like this. You can cut off a small piece and drop it into a glass of water. If it floats, It’s not ipe. There may be the odd piece of ipe that will float, but every piece I’ve tried this test on sinks so fast that it makes a noise hitting the bottom of the glass.

Just keep in mind that whether ipe floats or not (i.e., density > 1000 kg/m3) is also dictated pretty heavily by the humidity level where the wood was stored. It’s conceivable that what would be considered the “odd piece” that floats may be closer to the norm in extremely dry regions/conditions.

That is not an exotic wood. Could be long leaf pine.

This ipe wood covers the floor of my terrace. Previous owners have oiled the floor several times.The floor is worn, and doesn’t look good. It’s not possible to use a sort of Exterior Cleaner because of the naighbor below. Cleaning and removing old oil, will ledd to a lot of mess. Is it possible to sanding the floor, or will it destroy the durability and strukturere of the wood. The floor is expoce to both rain and snow.

Being so hard and strong, sanding will not harm it. I just pressure washed our deck and it looks good as new

the toxicity of this wood mentioned here is inaccurate. It is highly toxic, splinters in skin going septic almost immediately. Breathing the dust makes one a staff carrier and permanently susceptible to staff infection

Do you happen to have any references you can share? I’d be interested to hear more about this. I have no doubt that ipe is capable of causing some pretty negative effects on woodworkers, but as it stands now, with ipe being a fairly widespread commercial timber, there’s been quite a bit of studies done on the wood, and I’ve not heard of these particular claims before. Here is a summary of some studies that have been done on the genus: https://www.botanical-dermatology-database.info/BotDermFolder/BIGN-3.html The only thing I could find regarding Staphylococcus (i.e., staph infection) and ipe was a reference that extracts… Read more »

Being a carpenter, and having used a lot of Ipe, I can attest to it’s toxicity. Do not handle the wood without gloves, and never breath the dust.

Ipe is not highly toxic, contrary to what is posted on the web. It is allergic, but reaction is highly individual. I have been working with Ipe in my shop for 20 years and have no reaction. Splinters do not cause infection but may cause allergic reaction. Ipe is a natural disinfectant and is used as medicine by indigenous people.

I agree with Chris. I have built furniture and decks out of ipe. I only handle it with gloves – the nitrex gloves work great. And I always wear a an n95 mask. This way I do not spend my evenings removing splinters and coughing up black / brown flem.

The staff infection comment sounds pretty far out though

Are there any recommendations for removing painted graffiti from the surface of this wood?

Our city installed bridges and railings built from this wood in 2016/2017, and we would like to remove the accumulated graffiti – is sanding the best option? Any recommendations as to grit, etc?

Would a graffiti removal machine be too abrasive? Would power washing be likely to work?

Power washing is worth a try. It will not harm the wood if you spray normally

Acetone removes paint pretty easily with a rag and some light elbow grease, but I don’t know the extent of the graffiti and if that would take too much time. Keep in mind, this will also remove any finish from the wood. I use this process to remove paint splatter and old lacquer from antique rosewood tool handles.

Hi, Sarah. What city are you referring to?

Do you have papers\articles\data about ipe’s plantation on farms?

Hi, Isaac. No plantation-grown ipê is internationally traded for wood. Part of ipê’s usefulness comes from the density that accrues as it ages. Young ipê won’t work for applications and attributes people typically buy it for. The same could be said of cypress and Western redcedar, actually, which is why you still see ‘clear’ WRC being specified. But I digress. It’s important to remember that the term “ipê” can apply to over a hundred species of trees, some of which are small flowering trees. My understanding is that seven species are targeted for the trade as timber (which, I suspect,… Read more »

Having my non treated grey ipe deck cleaned with mild bleach solution to kill black mold. Do I need to put any moisture/restorative product after? I want to keep the non stained, natural appearance. Can I do nothing and let it “grey up”?

We’ve had ipe decks and a dock at a lakefront home for 20+ years. Search for ipe oil cleaner & sealer online. They sell a specific product. It must be oiled or sealed every 1-2 years, but it looks great in-between. Expensive but worth it to get the ipe-specific product. We tried other general sealers & oils in the past and they didn’t last as long or look as good.

Did you keep your deck grey? That’s what I’m going for and desperately hoping I don’t have to do anything. They now have been cleaned, no furring, feel smooth. Do I really need to do anything more? I’m pretty slothful.

Yes, and like teak on a yacht, it is the best there is

I would like to use ipe to make an outdoor living room, sofa and coffee table. What finish could I give it?

A penetrating oil sealer such as Penofin “For Hardwoods” is easy to apply and looks great. Needs to be refreshed every year or two, depending on exposure.

General Finishes Arm-R-Seal top coat (highest UV resistance of all top coats) Satin or Gloss.

Hello, I’m wanting to build some deadeyes, sailboat shroud tensioning blocks, I am wondering which strength metric would be most appropriate for the type of load these blocks will be taking. the blocks are fairly thick, round or triangular and have three or four holes for line to pass between them, creating a purchase system to tension sailboat standing rigging. The grain typically is horizontally oriented when looking at the face of the deadeyes. The rupture needs to be pretty close or the same as the rigging line, So I’m wondering if I should be looking more towards modulus of… Read more »

My only concern would be that lignum vitae has a very high natural oil content that I’m sure has a sort of self-lubricating property. If it were me, I’d be inclined to look for a piece of wood with some interlocked grain (which would be better at strength from lots of different directions). Ipe could do the trick depending on the individual piece, but there’s also woods like greenheart or bulletwood.

Lignums self lubricating properties actually lend themselves to tensioning this device, reducing the ropes friction passing through multiple holes under tension, usually these parts are well greased as well to promote friction free tensioning. We have techniques in rigging to tie these off in a way that they never slip loose once the desired tension is achieved, if this is what you were concerned about with the oily qualities? My biggest concern with lignum is getting big enough chunks to do all my pieces. The breaking strength of the rigging wire will be approx 24000 lbs, and the load on… Read more »

use lignum vitae

How about black locust?

Why is no mention about Yellow ipe?Eric Meier, do you need a sample?

I know is a bit rarer than red ipe , but I think deserves to be mentioned.

Do you have the scientific name for yellow ipe? In the United States, most ipe is usually just all lumped together and sold under one name of “ipe.”

“Handroanthus albus” is the scientific name.

Sorry for late reply I only a notification 5 months later.

Are you talking about Ipe Champagne, if so, it is actually Cumaru.

I’m talking about ” Handroanthus albus”

Hello,

Can ipe timber be dried in a drying oven?

All Ipe used commercially is kiln dried

Thank you for answer

As a knifemaker I can attest to the qualities of Ipe. It is difficult to saw accurately but it sands easily if you use the right grit of sanding belt and gentle pressure or you’ll burn the surface. The grain characteristics are great especially when you use bookend matching. As for durability you can’t beat it for the price. I’ve never had a problem gluing with epoxy or Gorilla Glue for wood to metal or Titebond 3 for wood to wood. Wiping down with acetone definitely helps. Have just finished a set of chef knives and a knife block for… Read more »

I’ve acquired some ipe and wondered if its ok to use in cutting boards. Is this wood ok to use for that?

Thanks in advance

not if you’re planning to use the cutting board for food. While the frequency of bad reactions is relatively low, I wouldn’t be willing to take the chance, and hope you don’t want to either.

Thank you for the response. Although I was hoping for a different answer, I’ll take your advice seriously and figure out another use for it. Thanks again.

A friend used Ipe cutoffs to make musical instruments.

We use tonka bean for cutting boards in the Caribbean.

Your knife edges will be dulled rather quickly. Recommendations for boards are woods between 800-1500 Janka hardness, preferably end grain so the knife can sink in and then when the knife is removed, the wood can close up after the cut. Even lower on the scale, there are very nice larchwood end grain boards if you go that route.

We have installed an IPE deck in exterior more than a year ago. It is beautiful with dark brown color and performing perfectly fine.

Got BazilianIpe sample for my future deck, left it outside (sun and some rain) and found a large crack after 3 weeks. Is this real Ipe?

Difficult to know just by words.

Ipe can present all the diffects other woods have. Remember that a decj have to be sealed or protected.

Yes. Ipe does crack.

Can Ipe Wood be used for kitchen countertop?

most likely. should probably be sealed with epoxy or something to avoid potential rot

Is Ipe sustainable?

It depends, here in Brazil yellow Ipê is one of the most popular Decorative trees used in our streets, but its ocurrence is endandgered in our forests due to illegal extraction.

Ipê is definitely not sustainable in terms of its logging. As I wrote above, almost the entirety of ipê coming into the U.S. is logged from the Amazon, either Brazil or Peru. It was, for a time, the single largest timber export out of Brazil and made so much money for illegal loggers it was called the “green gold of the Amazon”. I could write so much more about the rise of ipê (for twenty years, it was our top priority wood to try and get people to stop specifying, and after that time, we finally got New York City… Read more »

How do you pronounce Ipe?

Like Ebay but with a “p”. Epay – at least that’s how I pronounce it.

To my knowledge that is the correct pronunciation.

Ipê is a native brazilian word meaning “tree with hard bark” and you should pronounce it I (like the I in Indian) Pê (like in Pension).

Client wanting to use it IN an 8′ x 8′ spa to create a non floating shallow “Kiddy Pool” Is this a toxic/bleeding condition, and same question if using teak with it as well for final product?

Hard to say, but I doubt that anything that would leach out of the wood would be any more dangerous than chlorine anyway. There’s a chance there may be discoloration of the water though, which might not be aesthetically pleasing. I’m not sure that teak would sink, if that’s what’s intended by “non-floating” pool.

Mahalo Eric… that’s why the Ipe is part of structure to keep it from floating. Know there might be organic issues conflicting w/ pool chemicals and possible stain of tile? Wish a scientist could weigh in as most concerned about adverse effects for little kids if any, as both dusts are BAD for us, and if it could off gassed ??? into water? Thank you for your reply, mate

Watch out with Bolivian IPE for decks…nowhere as trouble free as Brazilian variety. MUST BE SANDED each year to remove checking and then two costs of Tung oil. Wood also moves a lot so expect gaps here and there.

I make segmented bowls, among other things. I have a request from a customer for a salad bowl made from IPE. From reading the comments and specs, it looks like a waste of time. Any suggestions?

Why do you say it would be a waste of time?

I don’t have carbide turning tools, and it sounds like HSS dulls very quickly, so lots of sharpening after very little turning. I’m also concerned about glue joints holding. In a segmented bowl, there are lots of end-grain glue joints.

It’s hard to say how things will hold together long term, but I think most problems with ipe glue joints have to do with being in direct sunlight and heating up. I’ve done a segmented turning in ipe, and I didn’t find it to be too much different than other exotics in terms of how it handled or glued. If I remember correctly, I believe I used polyurethane glue to hold things together.

Thanks Eric. I’ll give it a shot.

have you thought about using epoxy ? I use it with great success with hard to glue woods

Although most/all typical epoxies can/do have issues with UV light, Salt Water, Harsh Weather in general; I’ve recently rediscovered “Resorcinol-based” glue for outdoor/exterior applications – I’ve worked with it a lot in my distant past when rebuilding/repairing Boat Docks in marinas. Wooden Boat Builders use it as well. It’s well known to do extremely well with bonding oily exotic woods such as teak. It’s a two-part system, so typically a powder mixed into a liquid resin, but 2 liquids are also available. NOTE: most Resorcinol ones contain FORMALDEHYDE, so not a good choice for Eating/Food/Bathing applications? I have not dug… Read more »

Wipe it down with acetone where you’re putting glue. The acetone cuts the surface enough to allow a good glue joint. This is a handy treatment for any hard-to-glue joints.

Has anyone experienced an allergic reaction to an IPE wood deck?