Common Name(s): Black locust, robinia, false acacia

Scientific Name: Robinia pseudoacacia

Distribution: Central-eastern United States (also widely naturalized in many temperate areas worldwide)

Tree Size: 65-100 ft (20-30 m) tall,

2-3 ft (.6-1 m) trunk diameter

Average Dried Weight: 48.0 lbs/ft3 (770 kg/m3)

Specific Gravity (Basic, 12% MC): 0.66, 0.77

Janka Hardness: 1,700 lbf (7,560 N)

Modulus of Rupture: 19,400 lbf/in2 (133.8 MPa)

Elastic Modulus: 2,050,000 lbf/in2 (14.14 GPa)

Crushing Strength: 10,200 lbf/in2 (70.3 MPa)

Shrinkage: Radial: 4.6%, Tangential: 7.2%,

Volumetric: 10.2%, T/R Ratio: 1.6

Color/Appearance: Color can range from a pale greenish-yellow to a darker brown. Tends to darken to a russet brown with age. Can be confused with osage orange and honey locust in some instances.

Grain/Texture: Grain is usually straight, with a medium texture.

Rot Resistance: Rated as very durable, with good weathering characteristics. Frequently used as fence posts for its outdoor longevity.

Workability: Overall working characteristics for black locust are mixed: although the grain is usually straight, its high density and hardness can make it more difficult to machine when compared to other domestic hardwoods. Black locust also has a moderate blunting effect on cutting edges. Responds very well to both lathe turning and steam bending; glues and finishes well.

Odor: No characteristic odor.

Allergies/Toxicity: Although severe reactions are quite uncommon, black locust has been reported to cause eye and skin irritation, as well as nausea (less common). See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Black locust prices can vary depending on location, but prices should be moderate within its natural range. Those living in the eastern United States can expect prices to be comparable to white oak. In other areas where the lumber has been imported, the prices can be much higher.

Sustainability: This wood species is not listed in the CITES Appendices, and is reported by the IUCN as being a species of least concern. Furthermore, the species has become very widespread, and is even considered invasive in some areas. [1]Vítková, M., Müllerová, J., Sádlo, J., Pergl, J., & Pyšek, P. (2017). Black locust (Robinia pseudoacacia) beloved and despised: a story of an invasive tree in Central Europe. Forest … Continue reading

Common Uses: Fence posts, boatbuilding, flooring, furniture, mine timbers, railroad ties, turned objects, and veneer.

Comments: Black locust is a very hard and strong wood, competing with hickory (Carya genus) as the strongest and stiffest domestic timber: but with more stability and rot resistance.

Although it shares a similar common name with honey locust, the two are in separate genera—Robinia and Gleditsia, respectively. (In a botanical sense, black locust trees are actually more closely related to desert ironwood (Olneya tesota), though the wood of course is less dense than ironwood.[2]Lavin, M. (1995). Phylogenetic systematics and biogeography of the tribe Robinieae (Leguminosae). Systematic Botany Monographs, 1-165.) But when compared to honey locust, black locust tends to be slightly heavier, harder, and with more of a green or yellow tinge, while honey locust tends to have a warmer orange or red tint. For more information on separating lookalikes, see the notes on anatomy below.

Images: Drag the slider up/down to toggle between raw and finished wood. The first sample shows a piece that has already aged to a darker brown heartwood color, while the second sample is closer to the color one could expect from a freshly cut piece.

A special thanks to Steve Earis for providing a wood sample of this wood species.

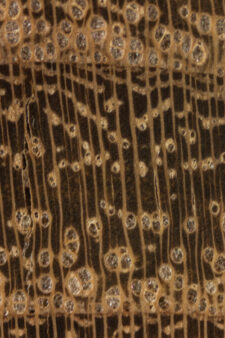

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: ring porous

Arrangement: earlywood in rows two to three pores wide, latewood in clusters and tangential bands

Vessels: large in earlywood, medium in latewood; tyloses abundant

Parenchyma: vasicentric and aliform

Rays: narrow to medium width; normal spacing

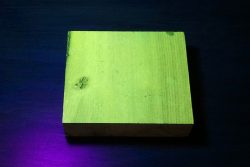

Lookalikes/Substitutes: Can be confused with other ring-porous hardwoods from the Eastern United States, such as honey locust, Kentucky coffeetree, osage orange, and red mulberry. However, black locust is the only species of the aforementioned group that features both abundant tyloses as well as fluorescent heartwood (when viewed under a blacklight). If a blacklight is unavailable, osage orange also features abundant tyloses and can be confused with black locust. However, fresh osage orange shavings, when mixed with a small amount of water, will discolor the water a yellowish color, while black locust shavings will cause little to no discoloration.

Notes: Heartwood fluoresces a vibrant yellow-green under a blacklight.

This genus only contains a handful of species, ranging from four to eleven recognized species depending on the author. Besides R. pseudoacacia, most species are shrubs or small trees, all of which are native to North America, and no other species are regularly utilized for commercial lumber.

Related Content:

References[+]

| ↑1 | Vítková, M., Müllerová, J., Sádlo, J., Pergl, J., & Pyšek, P. (2017). Black locust (Robinia pseudoacacia) beloved and despised: a story of an invasive tree in Central Europe. Forest ecology and management, 384, 287–302. |

|---|---|

| ↑2 | Lavin, M. (1995). Phylogenetic systematics and biogeography of the tribe Robinieae (Leguminosae). Systematic Botany Monographs, 1-165. |

This is by far one of my favorite woods to work with, even though its hardness can be a pain at times XD I think it’s a beautiful wood, and the UV glow is just a bonus. Worth saving even smaller pieces too since, due to its hardness, it does wonders for small joinery work! When you’re limited to using small dowels/pins or need an annoyingly small/thin wedge for a project/joint keep this stuff in mind! It’s a pain to find in my area despite growing all around here, at least in terms of woodworking material. And the few times… Read more »

Black locust has been used as street papers. In some areas they are used as driveway pavers.

I cut the tree down like 2 years ago and kept it because the wood looked kind of yellowish and then didn’t find out until just about a month ago that it fluoresced like this

One of the coolest woods I’ve ever come across

Whoever says that Black Locust has no Distinctive odor must not have a great sense of smell. That or my nose has a special kind of sensitivity specific to this wood. Everytime I work with it, I can taste it(/it sticks in my sinuses) for DAYS… Same smell as the bean pods that the tree drops. It’s actually mildly unpleasant… Reminds me of chewing on the pods as a kid…

I can definitely smell it as well, though I find it pleasant believe it or not. It reminds me of some condiment, but I can’t think of which right now.

I find the smell to be distinct but fairly neutral, not particularly good or bad.

Part of me knows it’s not the best wood to inhale (not that any wood is “good” to) which I think balances out the positive association the smell has with woodworking for me

Has anyone had any issues with Black locust molding?

Indoors it’s fine. In an outdoor setting any sapwood will mold quickly (and will decay off). Mold is not decay. Any fungal growth -is- decay. If the product was milled from a tree that had any type of shelf mushrooms or mycelium or spalling – it will continue to decay. Most common reason for mold growth is installation on north side of a home and/or applying something like linseed oil (that will turn anything jet black with mold fast). That is why deck finishes are loaded with mildewcides (which degrade over time). Best finish for deck boards is no finish… Read more »

I’m rebuilding this outlook deck with black locust, previously Ipe.

I’m hoping that black locust is a good substitute to Ipe… Time will tell.

We have a 2 1/4 mile Ipe boardwalk here at Corkscrew Swamp Sanctuary.

When the Ipe boardwalk was installed in 1994 we were told that it would last 50-75 years… 25 years later we find ourselves looking at having to replace the whole structure all together. Still 25 years is pretty good for a wood that was never sealed or treated. The Florida elements are brutal.

https://corkscrew.audubon.org/

We built a 2nd story deck on the south side of a home with locust deck boards less than 15 years ago and they completely rotted. It was clear, quarter sawn, heart wood from large, defect free trees. I was shamed into installing locust deck boards vs ipe on the large L shaped west and north facing deck on our private home. So far almost 30 of the boards need to be replaced due to rot. Here in Asheville it is now scarce and costs the same as ipe. Even if it were a lot cheaper (which our deck was)… Read more »

That REALLY sounds like you’re experiences have been with Honey Locust and not Black Locust…

I don’t want to sound like I’m totally against locust (black/yellow – obviously not honey). I am CONSTANTLY using it for exterior trim, deck rail posts (interior & exterior), bar tops, flooring, etc etc. It’s one of my favorite species. The best advice I can give is to source the material from a knowledgeable supplier. I inspect the logs/trees for shelf mushrooms, decay, etc. I no longer rely on the knowledge or integrity of others during that crucial stage. Then working with my sawyer we process the logs accordingly. Again, if the cost of BLACK aka YELLOW locust deck boards… Read more »

Hey, that’s fair enough. I personally mill all of my own locust myself from trees removed from local properties so, I have the advantage that you speak of. I also don’t use it for decking. I use it for tools, chests, cabinets, shelves, and my workbench (also sometimes for signs.) I love it but, I agree that I would never use it for decking.

Never? Have you used locust decking KD 12 to 14% with no pith?

I have not. I actually have never done any kind of decking. I just personally wouldn’t waste this wood on decking. It’s one of my favorites, by far, and I would rather use it for other applications. That’s just me, though.

If you know where to buy locust and don’t use the first 10 or 12 years of growth, it’s very durable. You possibly had a bunch of juvenile wood. Was it it all 3.5″ wide quartersawn?

Sounds like your negative experience with black locust is from juvenile growth and not mature outer growth. Look at an old split rail fence at a state park. Older fences show the 1st 10 or 12 years of growth have rotted away and the wood remaining sound is the outer mature wood.

Agreed- it was not Black Locust. The New Englanders used to say —in reference to Black Locust Fence Posts — “It lasts one day longer than stone”. I have worked extensively with the wood and the items I have built that are outside year around have zero indication of rot.

Interesting Cosmo. Where did you get the Locust ? Was it plantation grown from Hungary or Serbia ?

Sounds like you were not working with black locust you must have been using the sugar locust which is not recommended for exterior use.

From what you’re telling, I seriously doubt that your boards were black locust. I tore down a fence made of black locust, some years ago. That fence was older than me – built by my grandfather which died many years before I was born. Also, that fence never saw any drop of varnish, paint, oil or any other kind of finish. Aside from a thin layer of grey wood on the surface, caused by the sun, the wood inside the posts was healthy as new, only extremely dry and rigid. And strong like iron – you could neither hammer nails… Read more »

I have not. Not green or KD. Have you ?

Here is a kitchen island counter top with general finishes arm r seal. It glued up the best using Elmer’s wood glue max.

Wow! That is very nice.

Turned some live edge bowls from a Black Locust log I found in the woods. Pretty good to work with. Pretty grain.

Black Locust is not food safe

Could you explain more, on a two year old thread.

https://ediblealchemy.co/edible-invasive-plants-black-locust/#:~:text=Can%27t%20Beat%20It%3F,locust%20tree%20(see%20below)!

Made a deck earlier this year (decking and dimensional lumber) out of black locust. Was an absolute pain to work with…Heavy wood, pre-drilling, countersinking, massive clamps. Beautiful results though and everyone comments on how sturdy it feels. Definitely a different look than cedar or PT. Put it down green after sitting for a few weeks in the sun. Laid boards tight together, some shrinkage to where there is now a reasonable gap between the boards. Sealed with Cabot oil and its holding up nicely with no noticeable movement, warping after the weather change to fall/wet weather. Used an Amish mill… Read more »

I make make primitive bows and my wood of choice by far is Black Locust. I’ve made takedown bows with 30 year old mismatched billets. I’ve cut staves from logs laying on the ground for 2 years and was shooting 54# draw weight 7 days later. It is the classroom of bow woods. Incredible because it is so consistent. Loves dry heat for bending.

Bends under dry heat? Good to know. Learning about black locust, hoping to start a recurve this winter.

Does Black Locust need to air dried before Kiln drying

No…you can stick it in the kiln green right off the saw. Will just take longer to KD.

can’t do the camera But I did a wide plank bl. locust floor and the wood planks I “tanned” in the hot July Sun, the wood turns a great orange/brown and highlights the grain, but you have to be clever about warping. I did a pretty good job of it. can apply water mist covered by thin plastic overnight and the “U” warp flattens out. 5 days max for the color change in the sun. any more does not add to it.

My plan is to make kitchen countertops of heartwood black locust 2 x 5’s (true measure) planks. The rough cut planks air-dried for 20 months, and then the planks were fine-milled for direct use. I’ve read that stainless steel screws are best to join the planks. But I’ve read conflicting advice on gluing black locust planks together. Also, what best to seal the finished product OR can I leave the planks unfinished? Can anyone with experience give me advice? My thanks in advance.

Steve, SS 305 for sure and our Robi Oil is specially made for BL.

Pure Tung Oil is a great food grade finish that i like to use on butcher blocks. Just ventilate well, takes a couple weeks for it to cure and air out but it isn’t a harsh chemical smell.

I have made kitchen counter tops with black locust. The best result with glue I got was with using Elmer’s wood glue max. The planks I used were 6-11″ wide

I’ve done a ton of glue ups using Titebond II with no issues. Of course the success to any glue up is proper joining which will result in minimal clamp pressure. Excessive clamp pressure to join boards is a recipe for failure. I stick with Waterlox polymerized tung oil. The only steel that should come into contact with locust is stainless steel mainly due to tannin bleed. I’ve used exposed fasteners on all kinds of projects and the SS actually looks pretty sharp against the orange/brown locust hue (UV exposure will bring out that unique hue). Beware of significant knots.… Read more »

A beautiful wood, for certain. A pain to work as well. Absolutely worth it though. I make stunning coasters from Black Locust after applying a Lichtenberg burn. The way it glows under UV light is captivating. I’m not 100% on the terminology but the coasters I’ve made are cut from stumps where a smaller tree has grown into a larger tree. I take off the smaller tree and then use that to saw into small slices. I saw someone me mention something about “oyster” and one shape absolutely looks like an oyster or clam shell. Another looks like a brain.… Read more »

Coppice. You can keep regrowing from the stump.

Black locust guitar back with nice figure and chatoyance, and it sounded great. Unfortunately it is rare to find pieces you can get guartersawn guitar backs from.

This is beautiful and I absolutely love it

Thanks! Top is Port Orford cedar. One of my best sounding instruments. If you ever mill any clear quartersawn locust at least 8″ wide, please offer it to a local luthier! Story about wood stability: I gave the guitar to my brother-in-law in Las Vegas, and in a few months the back cracked in the dry desert air. One side of the crack actually curled up 1/2 inch away from the body. He shipped it back to me in North Carolina, and after a month in our 50% humidity, with weight on the crack, the wood relaxed and laid back… Read more »

I have a Black Locust and a Northern Catalpa tree on the edge of my property. Both are 4’+ at the base. I live on the old Pennsylvania RR right of way in Indpls. These trees are probably 200 years old.

Wow. Those are dandies! I found a 3 footer yesterday. Happy tree spotting.

Brian

Here in western WA, i see scattered black locust trees in right-of-ways typically 3 to 8+ inch dbh that grew from nearby stumps and naturally spread seeds. Similar to wisteria bushes, it is extremely invasive in sprouting from established plants. Can recommend riving to make tool handles, stool legs, outdoor furniture, and handrails. Epoxy glue appears to work best – not recommended for aliphatic (yellow) or white glues. Interlocked grain is difficult to plane evenly.

Thanks for the info.

I have a huge Black locust I have named the “ locust monster “ here in Frederick Maryland, USA. It’s leaves are awe full to try to clean up since almost year round ( not winter ) they ha e a tendency of falling, and due to their small in nature size they get in the smallest or biggest cracks crevices, clog gutters, create ice damming, stain anything they land on that you don’t remove them from immediately, etc. it has 2 more locust monsters coming out of it and measured over 70 ft. Does anyone here know if I… Read more »

I recently got some dark brown almost black wood that the person who gave it to me identified as baked locust. He said the color came from the baking process that increased the woods resdistance to insects and rot.

Does anyone know where I can obtain more?

Russ, the baking process is an issue. There are several companies doing it in the US and Europe but it is sketchy. It significantly weakens the lumber by carbonizing the sucrose. We tried this lumber several years ago in several species and distributed it for a year. We stopped because it does not live up to it’s claims.

This is correct, if you KD BL or bake it above 225 you actually destroy the cell structure of the wood and it destroys the rot resistance.

Brett, thermally modified woods are heated wood up to approx 360 to 400 degrees and it “changes”, not destroys, the cell structure and actually makes it MORE rot resistant. It does lose some strength…but its still plenty strong enough for decking. The thermal modification process also makes wood more stable as it’s hygroscopicity is reduced. Also, saying robi oil is specifically made for black locust is quite a stretch. Penofin, Cutek, and others work very welll on black locust. I’ve used all 3 on black locust. Robi oil ingredients are very common ingredients that many other brands also use for… Read more »

We’re about to start renovations on a small residential project in south Florida and would love to incorporate black locust into various elements. We’re considering everything from roof fascia to ceiling panels to kitchen cabinets to bris soleil. It would be great to get some thoughts and input from this amazing community, especially as I have no experience in construction nor woodworking. Has anyone had experience with charring black locust in a shou sugi ban style? Separately, does black locust do well with the wildlife in a tropical climate, especially insects (e.g., carpenter ants, termites, etc.)?

In romania there are black locusts everywhere,in any city or garden and on every road.Its such an invasive specie that became so common until it made people here think its a romanian native tree.Its not cut for lumber ,even if its hard and looks almost like ebony and probably even beats somme of the ebonyes at darkness.The main purpose for what its planted here is for the bees,because it makes a verry clear almost like water honey thats expensive.Basically every beekeper here plants these trees all his life and somme even plant forests.In europe,romanian black locust honey its verry famous… Read more »

Almost a year ago I bought a guitar made by Hora (based in Romania). They make an ‘eco’ series of classic guitar that uses spruce (top), maple (technically, sycamore maple ..I think, for back/sides) and BL for fingerboard and bridge. All woods are solid, not laminates. It’s considered a low-budget mass production instrument (at least based on price) that uses the classic Torres design. All in all though, the combination of woods look, feel and sound great — sonically, it works. The choice to substitute BL instead of EIR is a brilliant choice IMHO. Most of the basic characteristics are… Read more »

My favorite wood for walking sticks and canes.

Does anyone know how long it will keep its fluorescence? Is it lost once dried?

In my experience, it will keep its fluorescence even after it has been dried. Some woods seem to have a diminished fluorescence as they age, but age doesn’t seem to affect black locust much…

Thanks. That does make it an interesting prospect for turning.

Hello every body,

Can anyone recommend me some suppliers of Robinia wood in Europe? I am looking quite big quantities of this wood.

In Europe a good start would be Hungary, 22,5% of all forested area is robinia, that is ~460k ha of forest.

I’m positive that you’d find what you’re looking for, whatever the quantity.

One note of caution: With all its positive attributes you may be tempted to plant Black Locust on your property. Be aware that it is somewhere near the top of the scale for invasiveness! I sprouted 5 seeds a few years back and planted them in a corner of my lot. Three years later there were locust sprouts coming up in a garden 70 feet away from the little trees – and the trees had not borne seeds yet. But they had sent out finger-sized roots 100 feet long, seeking fertile ground and ready to create new trees from any… Read more »

I have to agree, we had two trees and cut them down and the roots sprouted literally hundreds of new trees all over our lawn and under our deck!

We cut the trees down 5 years ago and still have to dig up roots and trees.

I have 50 acres in central PA. Black Cherry, Red Maple, Mulberry, Alanthus, Black Walnut and Black Locust pop up like weeds everywhere. I spend several days each year clearing the seedlings from fields and fence rows. Black Locust over 12 inches in diameter has often started to hollow already. The trees may look solid, but they are brittle and tops break off making it dangerous for tree cutters. I do like the smell of the Black locust blossoms in the spring. Reminds me of orange blossoms.

The blossoms are really tasty too. like sweet peas

Black locust is a toxic plant due to the toxalbumin content, most animals can’t eat it without getting sick. I suspect that’s why it lasts so long outdoors without surface treatment, the toxins in the sap kill off mold, mildew, and many bugs. I see paper wasps on the lumber and where they’ve taken their bit of the nest off a cured board. I built a deck out of it a few years ago and it’s now a really nice shade of grey after a summer with plenty of sunlight. Every splinter I got while building that deck made my… Read more »

Jet: I’ve been thinking about trying black locust as a replacement for pressure treated when rebuilding my own deck. Where did you find dimensional black locust suitable for a deck? What difficulties did working with it present? And how has it weathered?

There’s a lot more. Like cedar it’s resistant to water because of specialized storage cells that keep moisture from entering. It also has it’s own type of flavonoid which is a strong antioxidant which keeps oxidation away. Many other things keep fungi mold and bacteria from degrading it. Bugs however can get into black locust although it’s a last resort.

In my area (western USA) you can control it with animals. I’ve been grazing cattle and sheep on black locust silvopasture for over 15 years with no problems. It’s ability to sucker and the species prolific growth make it invaluable as summer and drought forage. Posts and rails are an added bonus.

Grows like a weed — at a height of 25′ you have three 8′ sections to be quartered and the result is 12 fenceposts. Working with one other guy, and setting aside land and materials cost, we had a system where we were producing $192/hr in cash and carry inventory and could scarcely keep up with demand when we were 25% cheaper than an inferior product at nearby farm supply stores.

Anyone have any ideas on how this would do as a striking tool handle? Primarily an ax or hammer handle?

it is excellent.

Watch splitting as it dries. It’s bad about that. Dry slow.

While cutting a large oak into firewood I lost my splitting wedge. I cut two wedges from a piece of black locust (we call it robinier here, after the king’s gardiner, Robin (hence it’s latin name Robinia Acacia) who brought it here from America in 1604) and split 2.5 cords of oak with them. They haven’t died yet. Miracle wood that should replace all resistent exotic woods. However, due to its toxins I would avoid using it for a kitchen counter. In my experience, ash is the best for counters as it leaves no taste that might alter food, followed… Read more »

I am planning on making a 10 – 12 ft. long chisel ( actually i will be attaching a chisel to one end ).

The purpose is to chisel off growths high up on a tree trunk. I will be hammering from the lower end – maybe with a wood maul – or using it above my head to continuously jab away .

I am considering white oak, black locust and dogwood however maybe there is another type of domestic wood more suitable?

Does anyone with more wood knowledge than me have any ideas, recommendations or suggestions?

Hickory!!

Nice to find this site. I am amazed by Black Locust having so many advantages. Being a hard wood being able to thrive in temperate climate will make it a candidate for replacing the need for rainforest trees which is great. And also having the asset of being a legume which reduces the need for fertilizer, and this is just a few things… I have put some info together myself on Black Locust that may complement the interesting info on this site: https://hub.me/aeHwO

Your locust link is dead.

When finding a black locust tree, it is recognizable from its coarse bark, it’s leaf pattern and its white flowers although there semm to be some new yellow flower cultivars such as Robinia pseudoacacia spp “Frisia” , resembling closely Laburnum anagyroides trees who are also Fabaceae and bear similar flowers and grow in the same regions, same climate. Laburnum trees have (unlike Robinia)a smooth and thin bark, and the leaves are alternated differently, but the wood is pretty similar, once expose to light, the creamy yellow Black Locust will resemble the initially honey light golden brown Laburnum , only one… Read more »

This wood is very hard and i think quite a beautiful wood. Contrary to the description above, it has a very peculiar smell that is at first agreeable but soon becomes a bit too pungent /disagreeable. Over the course of a day of milling i realized the i was developing a sensitivity ( allergy) to the wood. I got a low grade nausea and a head ache. The next day i tried milling the wood without a respirator and soon found the headache coming on. Years ago making a deck out of western cedar I had a similar reaction. It… Read more »

Iworked three days with western Cedar and a week later was hospitallized with pnumonnia. Go figure.

This is an amazing web site and it’s sad I just came across it. To add to Michael’s and Randy’s comments, I grew up with black locust in the Colorado front range and we used it for all sorts of things. I love the smell of it. I recently worked with a piece, a lot of filing and sanding. Had my wife smell it and watched her turn green. Mind you, this was just the wood and not the filings or shavings. My son, liked the smell with no reaction. Too much cedar gives me a headache too.

I had four acacia trees in my yard cut down and sawn on the property. The wood is extremely hard and makes exceptionally fine wood for furniture. The wood takes stain well and once the moisture level gets down to 6% it machinabilty is excellent.The biggest problem is drying the wood to prevent warpage. I am now in the process of having two trunks that were cut down three years ago sawn into boards. When this is done I will know how the warpage works out. Once the warped boards are cut they remain stable and I have made several… Read more »

This species grows well when planted on farmland on the southern BC coast, and is a local favourite for crooks, knees and ribs in traditional boatbuilding. It is dimensionally stable and extremely rot resistant, similar but harder/tougher than teak. I find that working and sanding the raw wood does not irritate eyes or skin as much as teak does, but it does irritate the nasal passages, and also causes something almost like a mild case of asthma – constriction in the bronchial tubes. I highly recommend wearing a particle filter mask when working with Black Locust.