DATA SOURCE(S): 1,5,8,14,36

Common Name(s): African padauk, vermillion

Scientific Name: Pterocarpus soyauxii

Distribution: Central and tropical west Africa

Tree Size: 100-130 ft (30-40 m) tall,

2-4 ft (.6-1.2 m) trunk diameter

Average Dried Weight: 46.5 lbs/ft3 (745 kg/m3)

Specific Gravity (Basic, 12% MC): 0.63, 0.75

Janka Hardness: 1,710 lbf (7,580 N)

Modulus of Rupture: 18,380 lbf/in2 (126.7 MPa)

Elastic Modulus: 1,895,000 lbf/in2 (13.07 GPa)

Crushing Strength: 9,240 lbf/in2 (63.7 MPa)

Shrinkage: Radial: 3.1%, Tangential: 5.0%,

Volumetric: 7.9%, T/R Ratio: 1.6

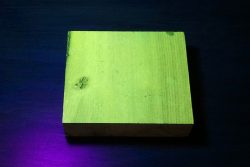

Color/Appearance: Heartwood color can vary, ranging from a pale pinkish orange to a deep brownish red. Most pieces tend to start a vibrant reddish orange when freshly cut, darkening substantially over time to a reddish/purplish brown (some lighter-colored pieces can age to a grayish brown). UV-inhibiting finishes may prolong, but not prevent the gradual color-shift of this brightly colored wood. See the article Preventing Color Changes in Exotic Woods for more information.

Grain/Texture: Grain is usually straight, but can sometimes be interlocked. With a coarse, open texture and good natural luster.

Rot Resistance: Has excellent decay resistance, and is rated as durable to very durable. Padauk is also reported to be resistant to termites and other insects.

Workability: Overall padauk is easy to work, though tearout may occur when planing quartersawn or interlocked grain. Padauk turns and glues well. Filling the large open pores is usually necessary if a smooth, glass-like surface is desired. Reactive oil-based finishes, such as polyurethane, may have curing issues if the heartwood is not sealed properly beforehand.

Odor: Padauk has a faint, pleasing scent while being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, padauk has been reported as a sensitizer. Usually most common reactions simply include eye, skin, and respiratory irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Widely imported as lumber in a variety of lengths and thicknesses, as well as turning and craft blanks (though with increasing levels of scarcity and trade restrictions.) Should be moderately priced for an import.

Sustainability: African padauk is listed in CITES Appendix II under the genus-wide restriction of all Pterocarpus species from Africa. Curiously, this popular commercial timber has not yet been evaluated by the IUCN and is therefore not on the Red List of Threatened Species.

Common Uses: Veneer, flooring, turned objects, musical instruments, furniture, tool handles, and other small specialty wood objects.

Comments: Padauk has a very unique reddish orange coloration, and the wood is sometimes referred to by the name vermillion. It’s moderately heavy, strong, and stiff, with exceptional stability. Padauk is a popular hardwood among hobbyist woodworkers because of its unique color and relatively low cost. It also occupies a sweet spot in density where it’s sufficiently hard and dense for higher-wear applications, yet not so dense as to be excessively difficult to work.

This wood species has a number of variant spellings and pronunciations, with a few being predominant. Padauk is the most common spelling, followed by padouk, paduk, and paduak. The most common pronunciation is pah-DUKE, followed by PAD-oak; it is sometimes mispronounced as Paducah—a city in Kentucky.

The unusual and decidedly non-Latin specific epithet soyauxii is in honor of Hermann Soyaux, a German botanist who went on several expeditions to West Africa in the 19th century. In addition to P. soyauxii, there are a handful of other less-common species sold interchangeably as padauk, such as P. osun and P. tinctorius.

Images: Drag the slider up/down to toggle between raw and finished wood.

A special thanks to Steve Earis for providing the turned photo of this wood species.

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; growth rings indistinct

Arrangement: solitary and radial multiples; mineral deposits occasionally present

Vessels: large to very large, very few

Parenchyma: diffuse-in-aggregates, winged, confluent, and banded

Rays: narrow (not visible without magnification); fairly close to close spacing

Lookalikes/Substitutes: Other African Pterocarpus species are also harvested and sold as padauk, such as P. osun, P. tessmannii, and P. tinctorius—as well as two Asian species, P. dalbergioides and P macrocarpus. Separation on a species level doesn’t seem possible based on macroscopic features. Bloodwood (Brosimum rubescens) is another popular hardwood with similar coloration that can be confused with padauk, though bloodwood is roughly 40% heavier, has slightly smaller tylosis-packed pores, and lacks the parenchyma bands seen in padauk.

Notes: African padauk heartwood fluoresces a faint to medium yellow/orange when viewed under a blacklight

Related Content:

Point of clarification for the author’s “Comments” section of the material’s description: Density has no relation to strength, toughness, hardness, or workability. Density is defined as mass (“weight”) divided by volume (lb./cu. in.). For example, gold and lead are far denser than titanium, yet very easy to precisely bend or machine, while doing the same to titanium is a comparatively nightmarish experience. Similarly, a gold bullet would simply deform and fall off of typical body armor plate made of a boron carbide ceramic (which is almost four times the hardness of pure gold), despite gold having almost eight times the… Read more »

Your claim that density has no relation to strength would only be true in the narrowest of vacuums. The problem is, we’re not in a vacuum, we’re dealing with a known material, wood. All wood is made up of cellulose, hemicellulose, and lignin, along with miscellaneous (less than 10%) extractives and mineral deposits. But the building blocks of wood are more or less constant, known materials, with the mechanical variability of each wood species primarily accounted for by differences in composition and anatomy of these elements. For instance, balsa is so light (and soft) because it has large, thin-walled cells,… Read more »

My Dean Exotica Acoustic Guitar in Paduk.

My Letts Woden Paduk Custom 27″ Bass in all Paduk. By Jon Letts. Report due to previous post having broken image.