|

Common Name(s): Bloodwood, Satine

Scientific Name: Brosimum rubescens (syn. B. paraense) Distribution: Tropical South America Tree Size: 80-150 ft (25-45 m) tall, 4-7 ft (1.2-2.1 m) trunk diameter Average Dried Weight: 66 lbs/ft3 (1,050 kg/m3) Specific Gravity (Basic, 12% MC): .90, 1.05 Janka Hardness: 2,900 lbf (12,900 N) Modulus of Rupture: 25,290 lbf/in2 (174.4 MPa) Elastic Modulus: 3,013,000 lbf/in2 (20.78 GPa) Crushing Strength: 14,310 lbf/in2 (98.7 MPa) Shrinkage: Radial: 4.6%, Tangential: 7.0%, Volumetric: 11.7%, T/R Ratio: 1.5 |

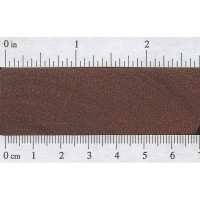

Color/Appearance: Heartwood is a bright, vivid red. Color can darken to a darker brownish red over time with exposure to light. Applying a thick protective finish, and keeping the wood out of direct sunlight can help slow this color shift. Well defined sapwood is a pale yellowish color, though given the typically large trunk diameters, it’s seldom seen or included in imported lumber.

Grain/Texture: Grain is usually straight or slightly interlocked. Has a fine texture with good natural luster, and is also somewhat chatoyant.

Endgrain: Diffuse-porous; large pores, few; solitary and radial multiples of 2-3; tyloses and other mineral deposits common; parenchyma winged and confluent; narrow to medium rays, normal spacing.

Rot Resistance: Reported to be very durable, and resistant to most insect attacks.

Workability: Bloodwood is extremely dense, and has a pronounced blunting effect on cutters. The wood tends to be brittle and can splinter easily while being worked. Those persistent enough to bear with the difficulties of working with Bloodwood to the finishing stage are rewarded with an exceptional and lustrous red surface.

Odor: Has a mild scent when being worked.

Allergies/Toxicity: The wood’s dust has been reported as occasionally causing effects such as thirst and salivation, as well as nausea. Can also cause skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Widely available in wide boards, as well as smaller turning squares and blanks.Many boards exhibit only a dull reddish brown coloration; truly blood-red pieces are the ideal. Prices are moderate to moderately high for an imported hardwood.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species.

Common Uses: Carvings, trim, inlays, furniture, guitars, knife handles, and turned objects.

Comments: Traditionally known by the name Satine, it’s no wonder that the wood (now more commonly called Bloodwood) has grown so popular as an imported wood species. Though it poses some challenges in working characteristics, its hardness, strength, and coloration make this a crimson favorite.

Table and benches – Bloodwood

I’m currently building an acoustic guitar with back and sides of bloodwood. I found a board with some unusual gran patterning that I was able to resaw and bookmatch. In the future the color will lose its vibrant red and go more chocolate but will still look amazing.

IME, bloodwood has been some of the absolute most brutal wood to resaw, so my hat’s off to you on this project!

Beautiful.

Bloodwood table project (2,86 m long 1,12m wide) -Newly cut and sanded planks ready for the next stage

Bloodwood bed I made for a friend who brought the wood back from Guyana after working there with the European Space Agency

We found some in the scrap bin at our local Rocklers. It’s rare that they have it. There’s just enough to make a couple of boot jacks from.

Are you sure that’s bloodwood? The pores look very large on those pieces, and if I had to venture a guess, I might say it’s something like jarrah.

That’s what Rockler had it listed as. They had a pallet of it and we got the last few pieces.

Hmm, interesting. I’d be interested in seeing a closeup endgrain image to help confirm/deny my suspicions. It’s possible that it was Australian red bloodwood, an unrelated Corymbia species (very closely related to Eucaltpyus). https://www.wood-database.com/red-bloodwood/

I have used this wood for many years to build flutes. Simply wonderful.

what finish do you use to preserve the color longer?

I use sweet almonds oil. It’s traditional on wooden recorders flute.

I’ve been looking at a board for about 3 years, finally bought it, made a bench. It’s incredible stuff.

Great wood when properly – slowly dried (preferably naturally). Bloodwood has a very interesting property: if, for example, a hole is drilled, the surface is very smooth, as if it were polished. If the wood gets very hot when sanding the surface with sandpaper, it does not crack, but some compounds contained in the wood harden, causing a varnish or wax effect. This is in contrast to the very rare Manoka/Andrampotsy wood from Madagascar (Asteropeia rhopaloides, weight 1200) which cracks when sanded if overheated. Bloodwood, despite its density, is very pleasant to work with. And a very nice smell, difficult… Read more »

I just used this wood for a fretboard on a guitar I built and it came out great. Wasn’t too troublesome to work, and I even did rolled edges. Try it!

Nice! Did you resaw the stock yourself? If so, how did it go? I have bloodwood stock for acoustic back/sides and fretboards but I kind of dread the resawing. Sounds like it will dull a Wood Slicer bandsaw blade pretty quickly.

I did put a bloodwood fretboard on an an acoustic a while back, using an LMII blank. I completely agree it is great for this purpose.

I didn’t have to resaw myself, my supplier had 6′ by 3′ by just over a quarter inch pieces which was perfect! I have made a couple guitars with it and it works great.

Hello. I just tried to resaw a 7,5“ piece for making a guitar back. I was not able to do it!!! (Just resaw flamed maple before it without any problems). When I get to half length, the blade drifted. Now the blade is not sharp anymore… This wood is very hard!!! Will try fretboard with another piece.

If you find a way to resaw it, please tell me! :)

My plan is to start with a brand new Wood Slicer blade and very careful setup. If the blade is essentially ruined after one back/side set I’ll roll that into the cost of the guitar. But I sure hate to treat a $42 blade as a disposable item. Will post results here after trying it.

does the wood slicer blade have carbide tips ? (I don’t believe so) – they’re pricey but man they do the job. Just switched to carbide turning tools for turning a pink ivory drumstick- wow – from pain to pleasure !

I think that wood requires a carbide-tipped bandsaw blade

Wood Slicers are conventional steel, but cuts are almost tablesaw-smooth and thin kerf. I have used them to resaw bubinga with great results. Maple, ash, sapele – no problem. But I’ll switch to a fresh blade if resawing expensive and problematic wood like bloodwood. Just found a saw shop a couple of hours away that claims to sharpen bandsaw blades. Planning on trying them out soon. If their prices are reasonable that would be wonderful.

Yes, In the end I was able to do it with carbide-tipped bandsaw blade. I bought two different ones from tufftooth and it works great! :)

Eric,

Is this the same wood that is in a few videos on YouTube claiming that the sap of this tree is the same color as blood and this the name? One video claims it’s from Africa, the other South America, Indonesia, and Africa. All the videos show a tree that looks like it could have been a double for the fake blood in Texas Chainsaw Massacre. I mean really grizzly.

I have just started surfacing the piece of Bloodwood I bought about 10-12 years ago. Might have been a few years north of that but fully seasoned and even had accidentally had a time where it was standing in a flooded garage about 3”. That end only slightly greyed, but none has warped or split. When I bought it, it was the cherry red you see often in photos, but has matured into the most beautiful cinnamon color that is almost iridescent(think the 3D aspect of figured maple, but there is no flaming or neat pattern, just the wood itself.… Read more »

Here are a couple photos. I’m still hand surfacing the board right now. So I took a photo of a section already surfaced and some of the plane shavings. I can’t get over how rich the color of this wood is.

Do you by chance have a picture of the endgrain of this wood?

I’ll take one when I start working on the project in a few hours. Right now it’s inferno hot, and I can’t deal with the heat anymore. But I will take a few for you and post them.

Eric here is one photo from each board. The redder colored one I had to run my block plane over it to knock down the saw marks. I tried to to make it too slick. The other is from a raw end. If you need something else please specify exactly what you want and I’ll try to make it happen. I do not have an SLR camera. The photos were with a iPhone XR and zoomed all the way in then I moved in until I was able to get the camera to focus.

Okay, thanks for that, the second picture is very good. The endgrain sort of confirms my suspicion, which is that you actually have a piece of padauk in the Pterocarpus genus. (Still a very fine hardwood!) https://www.wood-database.com/african-padauk/ The endgrain has very large pores and, most notably, very distinct and wide bands of parenchyma. (They appear in your second picture as the lighter colored bands that run horizontally across the wood.) You can compare this to the 10x endgrain picture of padauk in the linked page –hopefully you’ll see the similarity. Bloodwood doesn’t really have very distinctive or widespread parenchyma, and… Read more »

Well heck, if that is the case, then I need to go to two separate lumber houses 1500 miles apart and get some refund. I paid for Bloodwood/Sapele, and got Padauk. Ave half the price if not more. That’s the only thing you mentioned about this that is upsetting as the one piece was close to $180 when I purchased it so many years ago.

Eric, what is the parenchyma? Are those the pinhole looking portions of the end grain?

I can’t comment on any of the other pics/woods, so there may be two (or more) different species in play here. All I can say is that the second endgrain picture you posted shows a very distinct parenchyma banding that’s much more reminiscent of padauk, and lacking in bloodwood. For reference, the pinhole looking portions of the endgrain are just the pores. Parenchyma is the lighter-colored material that run in sort of horizontal lines in your picture. There are some examples of parenchyma on this page: https://www.wood-database.com/wood-articles/hardwood-anatomy/#paratracheal If you scroll down a bit, under the example of banded parenchyma, you’ll… Read more »

Yeah I’m sort of bummed that these boards aren’t actually Bloodwood. No big deal though. It’s still very attractive wood whatever it might be. I got a fairly large splinter from one yesterday that took me about 10-15 minutes to get to as I had to clean up some. Removed it and it feels like it is still in there. The immediate area of irritation is about the size of a us quarter. That area feels a little warm and itches. The spot where the splinter was hurts. I only made a small incision directly above the splinter and it… Read more »

Could it be Pterocarpus Angolensis DC? It’s a close family of the african padouk and is called bloodwood in South African countries, the reason being that the tree, when cut, “bleeds” a red latex-like substance which is used for its medicinal properties in wound healing.

Had forgotten the contrast photo. Board on the left still raw. Surfaced board on right

If you want a superior finish, lacquer isn’t it. Used on cars till the 30’s and then abandoned as it is the cheapest finish you can buy. Keeps on drying and then cracks like a dry desert. I now use Waterlox which is over 100 year product of natural tung oil with synthetic driers. Natural tung oil doesn’t really dry but waterlux dries at room temp in about 30 minutes to a tack free finish and then taken 7 days to fully cure. You can add coats in an hour or less but I usually just do one a day.… Read more »

I was not happy with my recent Bloodwood experience. I bought a couple medium sized boards which I am confident were fully seasoned. They were standing in a garage with reasonable climate control. When I had finally decided on what I would make with them I was amazed that both boards were bowed, warped, crowned, and cupped beyond use except for small items. I ended up making cutting board holders and a box. While working with the wood, I found that the grain chipped out very easily and decided any carving attempts would lead to a lot of frustration. Their… Read more »

If it’s bloodwood, it should be extremely ding resistant (Janka of 2900 !)

My experience with turning segmented bowls is bloodwood tends to splinter. Especially where the segments are end glued together.

Does anyone know if a waterfall grain patter with contrasting colors is rare for bloodwood?

That’s some really odd grain. It’s interesting what did you wind up making with it?

Just a quick question on the data section. The modulus of rupture and elastic modulus seem confused. It would seem to take less strength to bend (EM) the wood than to actually break it (MR). Yet in every case, the elastic modulus is the larger number.

On the current page, the EM would be 20780 MPa. Why would it be 119x harder to bend a piece of wood than to rupture it?

Could you clarify? Perhaps these numbers are inverted?

The two numbers are correct, and are very different measurements. MOR is more of an absolute measurement (how many # does it take to break the wood of a given size), while MOE is a ratio of stress to deformation. USDA has more info here: https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr190/chapter_05.pdf

I have two small pieces 5”x4”x3/4” of South American Bloodwood that my Dad put in a bag in 1958 with a note saying “save these because they are exceptional wood True ?

I guess it depends on your definition of “exceptional.” Maybe back in 1958 the wood wasn’t imported as often, but bloodwood is by no means excessivley rare or scare, all things consdiered. If it were me, I would value you it for sentimental reasons, and try to make something from the wood. Pen? Knife scales? etc.

I recently purchased a 6″x 6″ x3″ block of blood wood. When I cut off 1/8″ off end to remove wax I noticed checking cracks into the wood – bad. These cracks were obvious in the final polished carving. I really love the wood but reluctant to purchase more. Did I just happen to buy a bad piece or is this typical of bloodwood

I recently purchased a piece of Bloodowood and found no irregularities in it. But, considering it was my only Bloodwood piece to have turned, I’m not sure if that is more common than not. Though with the research I have done, it seems like you may have just gotten a bad piece.

Bloodwood has a nice deep rich color that’s very appealing to the eye. I have some turned princes here https://www.bostonwoodturning.com if you want to see them.

Anyone ever have a problem with bloodwood getting mold on it after finishing it with a liquid beeswax?? This occurs after I have finished it and store it for several weeks.

Made a couple yoyos out of bloodwood. Sell them on etsy https://www.etsy.com/listing/510156430/wooden-yo-yo-with-maple-inlay-perfect

I believe I have a few of these trees in the park I’m in at Acton CA USA. How they got here I have no idea. The leaves look like eucalyptus but bark is thick brown with clear red sap leaking out of the wounds. It is growing near a sandy wash with drainage as required. I’m going to cut a branch for a walking stick. There is a lot of sap from one I will collect for the medicinal properties. I’m melting some sap in my oil burner and it’s a really nice wood/flavored cigar smell – not at… Read more »

Are you sure it’s not a red gum, from Australia? That’s a type of eucalyptus, and the wood is very hard and red.

Bloodwood bowl on the lathe, this is after sanding and before applying any finish.

I really enjoy the smell of this wood while working with it. It smells like pipe tobacco. It may be an acquired smell, but I enjoyed it. I also found working with a router and a bowl shaping bit to work beautifully. Cut it on my table saw with a fine tooth blade and it came out great as well. No splintering or tear out. It’s hard as nails and sanding is a real bear, but overall it has been a joy to work with so far. No allergies for me when working with it. Did everything in a t-shirt… Read more »

Hi Thomas,

I was just reading your 2015 comment on blood wood, not splintering or tearing. Would you have the info what country this bloodwood came from? I’m looking to test it for my project.

Appreciate for your kind attention.

If you guys want to see something beautiful, burn the wood slightly with a blowtorch. Just hold the flame a couple inches away from the wood and burn it as if you’re painting. It makes the color so much deeper and brighter and once you put a sealant overtop of it, it makes it some of the most beautiful wood you’ll ever see.

Got any before and after pics?

I built a classical guitar out of bloodwood ,and it is gorgeous the book matched back looks like a wizard with a big hat and beard, it is hard and heavy wood and the guitar has a very bright sound, with good volume, I French polished it and the finish looks a mile deep

Yeah, I’m not getting where you’re coming from with this. All I am getting is wood that wants to char. Are you talking similar to how Japanese elm siding is made?

You’d more than likely have to pre-drill pilot holes.

Thank you for your advice.

definitely predrill – I’ve had bad results with my nail gun

I’ve also made about a dozen small-ish projects for my shop out of bloodwood due to the gorgeous color and luster. At this point I am discontinuing it unless a customer wants to pay double the price I used to charge for it. And that’s due purely to the challenges of working with it. I haven’t had too many problems but a piece I just finished was a NIGHTMARE. It’s always very inclined to splinter, especially on the router, but that hasn’t been a problem for me. I haven’t found tear out to be worse than similarly hard woods but… Read more »

I hand chop bowls. No batteries-no electricity! Just an adze and bowl scraper. I just finished a 10 by 10 by 4″ bowl. I’m giving it as a gift. The insides are smooth. Does anyone have experience with applying poly urethane and and good or bad experience with putting food in it ?? Not like hot soup or cold cereal, but fruit or salads??

I’ve lately been trying it as a fingerboard material. Works fantastic (comparable to Indian Rosewood) but you must take great care when cutting the fret slots (to avoid splintering) It’s slow work, particularly when shaping the wood on a planer, and I generally sand it to at least 1,000 grit before slotting. The occasional fret may not seat well due to the hardness of the wood. A light coat of dewaxed shellac (rubbed on in almost French polish fashion) gives enough strength to cement the frets if such is the case. If the frets do seat on first attempt, it’s… Read more »

I’ve been using Bloodwood for Bass and Guitar fretboards since the mid 90s and I love it.. I do prefer and recommend quarter sawn if you can find it, Plain sawn tends to warp easily and being as its so stiff it can be a serious problem on a neck. its very flexible and has a lot of “memory” would probably make a darn fine archery bow..

If you are cutting this wood indoors wear a mask and have a shop vac handy. It will look like the wood bled all over the place. The dust is so fine and powdery that it goes every where.

If you are using a power saw or table saw, I highly recommend cutting this one outside.

If you have wood allergies, this species will trigger the hell out of, definitely wear a respirator

I found it splinters if you look at it wrong. It can be thoroughly miserable to work with. I found severe tear out with the router, and some tear out on the lathe. If you are careful and can get past the machining, it sands and finishes well. With lots of care the finished product is spectacular. I’ve made several high-end walking sticks out of bloodwood, and those are the ones people reach for first.

Super sharp tools are the key on the lathe. Good luck keeping them that way, though :)

I have a custom bow made of bloodwood. It shoots so great and the color is so impressive that I’m sure the next one I have made will be also made out of bloodwood.

When I first purchased Bloodwood the blank was quarter-sawn, will this affect its workability if so what can I do?

~Trevor

Yeah, the sawdust & glue (or lacquer) trick works great with bloodwood. I’ve made a few boxes & rocking chair with it. LOVE this wood!

I’m thinking/planning a solid body electric guitar made out of bloodwood (quarter sawn, if possible — the iridescent-like quality of the grain is gorgeous). Trying to get some idea about the tone qualities of the wood first. I’ve heard comparisons to mahogany, which is what my SG is made of.

That is exactly what I am making with mine. Having to laminate the body like the old Ibanez Rockett Roll II. Just the two body pieces that will make tye top half of the body weigh more than my Gibson V. Which is what it will be modeled after.

I tried to use thin stripps of Blood woob for Guitar purflins & binding. It was very brittle. It did not bend will over a hot pipe so I put it in boiling water. I had some sucess bending in one direction but when I tried to reverse the bend at the waist but it splintered. I ended up with many joints in the purlins. I looks great after filling gaps with saw dust & super glue then sanding.

Love the mild aroma, and the iridescence of quarter sawn pieces. One of my favorites!

bloodwood is very hard an heavy.

difficult to carve, but a great color.

Bloodwood can often times have a very strong odor and can sometimes cause skin reactions. Take care when sanding it.

What is the odor you pick up? To my it’s mike a ground comino mixed with ground annato seed