|

Common Name(s): Spanish Cedar, Cedro Scientific Name: Cedrela odorata Distribution: Native to Central and South America and the Caribbean; Tree Size: 65-100 ft (20-30 m) tall, 3-5 ft (1-1.5 m) trunk diameter Average Dried Weight: 29 lbs/ft3 (470 kg/m3) Specific Gravity (Basic, 12% MC): .38, .47 Janka Hardness: 600 lbf (2,670 N) Modulus of Rupture: 10,260 lbf/in2 (70.8 MPa) Elastic Modulus: 1,323,000 lbf/in2 (9.12 GPa) Crushing Strength: 5,860 lbf/in2 (40.4 MPa) Shrinkage: Radial: 4.1%, Tangential: 6.2%, Volumetric: 10.2%, T/R Ratio: 1.5 |

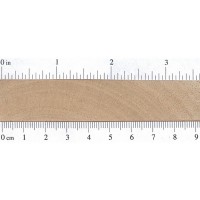

Color/Appearance: Heartwood is a relatively uniform light pinkish to reddish brown; colors tend to darken with age. Random pockets of gum and natural oils are commonly present. Grain patterning and figure tends to be somewhat bland.

Grain/Texture: Grain is straight or shallowly interlocked. Medium texture and moderate natural luster.

Endgrain: Can range from ring-porous to diffuse-porous; medium-large earlywood pores, small-medium latewood pores; solitary and radial multiples of 2-3; mineral deposits (red gum) occasionally present; growth rings distinct due to terminal parenchyma in diffuse-porous samples, or lines of larger pores in ring-porous samples; rays usually visible without lens; parenchyma banded (terminal), apotracheal parenchyma diffuse-in-aggregates, paratracheal parenchyma vasicentric.

Rot Resistance: Spanish Cedar ranges from durable to moderately durable regarding decay resistance, and is also resistant to termite attack; the wood is also reported to have excellent weathering characteristics. Older, slower-growing trees from the wild tend to produce wood that is more durable than wood from younger, plantation-grown trees.

Workability: Spanish Cedar is easy to work with both hand and machine tools. However, due to its low density and softness, Spanish Cedar tends to leave fuzzy surfaces if not machined with sharp cutters; extra sanding up to finer grits may be required to obtain a smooth wood surface. Also, natural gum pockets can remain wet and may ooze out onto the surrounding surface, which can clog and gum up saw blades, and make finishing the wood a challenge.

Odor: Has a distinct, lingering, cedar-like scent; this characteristic of the wood makes it a favorite for cigar boxes.

Allergies/Toxicity: Although severe reactions are quite uncommon, Spanish Cedar wood dust has been reported as a respiratory irritant. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Generally in adequate availability, Spanish Cedar is sometimes sold in thinner 1/4″ lumber for use in liners and other small craft projects. Spanish Cedar should be in the low to moderate price range for imported lumber.

Sustainability: This wood species is in CITES Appendix III, and is on the IUCN Red List. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation.

Common Uses: Veneer, plywood, cabinetry, musical instruments, (flamenco and classical guitars), humidors, and boatbuilding.

Comments: A historically valuable Latin-American timber, Spanish Cedar has been exploited in many regions, and the species is now considered to be vulnerable according to the IUCN. It’s also listed on the CITES Appendix III for the countries of Brazil, Bolivia, Columbia, Guatemala, and Peru. (It’s listing in Appendix III simply means that the countries listed have voluntarily chosen to control the exporting of the wood, and have sought the cooperation of other countries to help in enforcing these restrictions.) Spanish Cedar may still be freely exported from other Latin American countries not listed in Appendix III.

Not a true cedar, Spanish Cedar is actually more closely related to true Mahoganies (Swietenia and Khaya genera), as both are in the Meliaceae family. Density and mechanical properties can vary widely depending on country of origin and growing conditions; (specific gravity can vary from .30 to as high as .60 in some instances). Some of the wood available at present comes from plantations: where younger, faster-growing trees, produce wood that is lower in density, and paler in color than wood cut from trees taken from forests in the wild.

None available.

Image of the endgrain of Spanish cedar with a small amount of sapwood

I turned a bowel from Spanish cedar. It was a very dusty wood to turn but the end result was rewarding. I used food grade salad bowl beeswax .

All Cedrela species from the neotropics are now Appendix II

The best conga ever made in Brazil. Raul conga, with cedrela odorata wood.

I thought I’d leave a pic of a guitar with Spanish Cedar back and sides. The wood is quite lively.

That’s got to be some of the nicest looking spanish cedar I’ve ever seen! Interesting color and figure.

Nice!! Is it a steel string? Did you build it? How well did it bend?

Thinking of using Spanish Cedar for outdoor kitchen cabinet doors. If my objective is to have the Spanish Cedar weather-out to gray, should I treat it at all? If I do treat it at first, then let it weather, is that a better strategy for some reason?

When staining or painting Spanish cedar, use a clear wood epoxy. This seals in tannins and oils that would otherwise ruin the finish. We are a professional front door refinishing company.

Kerner’s Front Door Refinishing, covington La.

Flame spread and smoke rating for Spanish Cedar for a humidor building department is asking for info

Help??

Jim

Did you ever get this question answered. I am currently designing a cigar lounge with a 1,000sf humidor and the building official will be asking for this info. Any help or if you can guide me to the right location for the info would be greatly appreciated.

given the complaints about the naturally-coccurring oils, is there any problem using this as a tone wood for tops/bellies of stringed instruments?

I have in mind to use this for making my first Lute, which doesn’t need to be perfect as it’s a first attempt, but I’d like the instrument to be usable.

I have a hard time imagining what good this species would be as a soundboard, especially for a lute. Apart from its tonal properties–or rather, lack of them–I think you would find cutting the rose very difficult, due to the lack of strength in its grain. The traditional wood is White Spruce (Picea abies), which I would encourage you to use instead. You can get an ordinary, grade A Englemann spruce (Picea englemannii) soundboard set from StewMac.com for under $20. If you want to use Spanish cedar for something, use it for the neck and end-block, but veneer or edge… Read more »

Flamenco guitars traditionally have cedar tops. That is one way to tell the difference between a classical guitar and a flamenco guitar so I don’t see why you couldn’t use cedar on your lute. Look for older non plantation wood of the best quality.

This information is highly questionable. The earliest use of cedar soundboards by Spanish luthiers goes back only to the 1960’s (so hardly classifiable as traditional), and it was western red cedar (thuja plicata), not cedrela. Most cedar-topped nylon-string guitars I’ve seen have been classical type, not flamenco. Are you perhaps thinking of the use of cypress (rather than cedar) for the backs and sides of flamenco guitars?

Cedrela odorata soundboards are common on traditional Caribbean folk instruments- excellent tonal properties if quartersawn and minimal runout.

Tres cubanos made from Cedrela odorata date back to 1880s

Michel Collichon would like to have a word with you!

https://www.youtube.com/watch?v=Av20FgeJIok

I am a proffesional painter with over 40 yrs experience. Spanish cedar has oil pockets that seem to never dry, consequently paints (oil, acrylic, et cetera) bubble and peel over long periods of time. I encourage customers to use single coats of open coat paints like exterior oil stains or exterior waterborne urethanes. The oils tend to bleed through these paints and can be periodically washed off instead of creating blisters under paints that form a surface skin like gloss, satin and so forth.

you must use an oil base primer prior to any topcoats with this material. its oil content will react directly with latex paints

What do you mean? How will latex paint react to the oil base primer?

WE HAVE HAD DIFFICUTIES IN PAINTING THIS WOOD.PLEASE ADVISE.

See my comment re epoxy