DATA SOURCE(S): 1,6,14,43

Common Name(s): Zebrawood, zebrano, zingana

Scientific Name: Microberlinia brazzavillensis

Distribution: West Africa

Tree Size: 65-130 ft (20-40 m) tall,

4-5 ft (1.2-1.5 m) trunk diameter

Average Dried Weight: 50 lbs/ft3 (805 kg/m3)

Specific Gravity (Basic, 12% MC): 0.67, 0.81

Janka Hardness: 1,830 lbf (8,160 N)

Modulus of Rupture: 17,800 lbf/in2 (122.8 MPa)

Elastic Modulus: 2,374,000 lbf/in2 (16.37 GPa)

Crushing Strength: 9,210 lbf/in2 (63.5 MPa)

Shrinkage: Radial: 7.6%, Tangential: 10.8%,

Volumetric: 17.8%, T/R Ratio: 1.4

Color/Appearance: Heartwood is a light brown or cream color with dark blackish brown streaks vaguely resembling a zebra’s stripes. Depending on whether the wood is flatsawn or quartersawn, the stripes can be either wide and erratic (flatsawn), or somewhat narrow and uniform (quartersawn).

Grain/Texture: Grain is interlocked and/or wavy; uniform, medium to coarse texture with good natural luster.

Rot Resistance: Heartwood is rated as durable and is also resistant to insect damage.

Workability: The wood saws well, but can be very difficult to plane or surface due to the prevalence of interlocking grain. Tearout is common. Zebrawood glues and finishes well, though a transparent pore filler may be necessary for the large open pores which occur on both dark and light surfaces.

Odor: Has a characteristic, unpleasant smell when being worked.

Allergies/Toxicity: Although severe reactions are quite uncommon, zebrawood has been reported as a sensitizer. Usually most common reactions simply include eye and skin irritation. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Tends to be available in both veneer and lumber form, with good sizes available. Prices are high, even for an imported hardwood, though not necessarily as prohibitively expensive as scarcer African imports such as Gaboon ebony (Diospyros crassiflora) or pink ivory (Berchemia zeyheri).

Sustainability: This wood species is not listed in the CITES Appendices, but is on the IUCN Red List. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range. However, a closely-related (though lesser-used) species endemic to Cameroon, Microberlinia bisulcata, is also sold interchangeably as zebrawood and is listed as endangered.[1]van der Burgt, X. & Cheek, M. 2022. Microberlinia bisulcata. The IUCN Red List of Threatened Species 2022: … Continue reading

Common Uses: Zebrawood is frequently quartersawn and used as veneer. Other uses include tool handles, furniture, musical instruments, boatbuilding, carvings, turned objects, and skis.

Comments: Sometimes called zebrano, the wood is strong and stiff, with a fairly high density. However, the wood is much more frequently used for its bold and unique striping.

The species name, brazzavillensis, is named after Brazzaville, the capital city of the Republic of the Congo. Although the species occurs more frequently in West Africa, French botanist Auguste Chevalier (1873-1956) ended up using a specimen collected near Brazzaville, in conjunction with previous specimens from Gabon, to first describe both the species itself and the (then) new genus, Microberlinia.[2]Chevalier, A. (1946). Sur diverses Légumineuses Caesalpiniées à feuilles multi et parvifoliolées vivant dans les forêts d’Afrique tropicale et donnant des bois recherchés. Journal … Continue reading

Images: Drag the slider up/down to toggle between raw and finished wood. The wood samples pictured below:

- Microberlinia brazzavillensis, quartersawn

- M. brazzavillensis, flatsawn

- M. brazzavillensis, birdseye

- M. bisulcata, flatsawn

A special thanks to Steve Earis for providing the turned photo of this wood species.

Full board scan

(19.3″ 49cm x 6.9″ 18cm)

Full board scan

(16.3″ 41cm x 3.4″ 9cm)

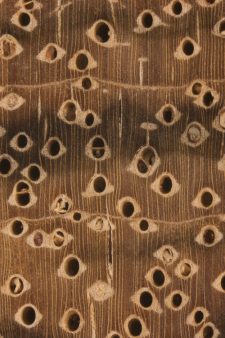

Identification: See the article on Hardwood Anatomy for definitions of endgrain features.

Porosity: diffuse porous; annual growth rings generally not discernible and stripe patterns do not strictly coincide with growing seasons

Arrangement: solitary and radial multiples

Vessels: very large, very few; brown deposits common

Parenchyma: diffuse-in-aggregates, vasicentric, winged, lozenge, confluent, and banded

Rays: narrow width, normal to close spacing; rays are generally not visible without magnification

Lookalikes/Substitutes: The dramatic striping of zebrawood is usually not confused with any other commonly-available hardwoods. However, there are some lesser known species that can have a similar appearance. Although Fabaceae is a vast and diverse botanical family, it is sometimes subdivided into smaller sub-families and tribes, with zebrawood falling in the tribe Amherstieae.[3]de la Estrella, M., Forest, F., Klitgård, B., Lewis, G. P., Mackinder, B. A., de Queiroz, L. P., Wieringa, J. J., & Bruneau, A. (2018). A new phylogeny-based tribal classification of subfamily … Continue reading Two other African hardwoods also in this closely related tribe are beli (Julbernardia pellegriniana) and ebiara (Berlinia spp.), with the latter even being being called red zebrawood on occasion.

Anatomically, all of these woods can be very similar, and generally gross features like overall color and scent can be more helpful to separate these woods. In general, zebrawood has an unpleasant scent when being worked, and tends to have the most consistent streaks, as well as the highest amount of contrast between the light and dark parts of the wood.

Notes: The two Microberlinia species, M. bisulcata and M. brazzavillensis can be sold interchangeably and are more or less indistinguishable. However, the endangered M. bisulcata is generally only found in Cameroon, so if the source country can be reliably ascertained as outside of Cameroon, M. bisulcata could probably be safely ruled out.

The Microberlinia genus contains only two recognized species, M. bisulcata and M. brazzavillensis. Both species are sold interchangably as zebrawood and are represented on this page.

However, even though the Fabaceae (legume) family is very diverse, it is sometimes subdivided into smaller sub-families and tribes, with zebrawood falling in the tribe Amherstieae. Some other genera in this tribe that bear commercial woods include Berlinia (ebiara) (though after DNA testing Berlinia‘s inclusion in the Amherstieae tribe is currently in question.[4]de la Estrella, M., Forest, F., Klitgård, B., Lewis, G. P., Mackinder, B. A., de Queiroz, L. P., Wieringa, J. J., & Bruneau, A. (2018). A new phylogeny-based tribal classification of subfamily … Continue reading), Julbernardia (beli), and Brachystegia (okwen)—indeed, Chevalier initially identified his early zebrawood specimens (decades prior to his 1946 description of the Microberlinia genus) as Brachystegia species.[5]Chevalier, A. (1946). Sur diverses Légumineuses Caesalpiniées à feuilles multi et parvifoliolées vivant dans les forêts d’Afrique tropicale et donnant des bois recherchés. Journal … Continue reading

Related Content:

References[+]

| ↑1 | van der Burgt, X. & Cheek, M. 2022. Microberlinia bisulcata. The IUCN Red List of Threatened Species 2022: e.T30441A67802206. https://dx.doi.org/10.2305/IUCN.UK.2022-1.RLTS.T30441A67802206.en. Accessed on 23 July 2024. |

|---|---|

| ↑2, ↑5 | Chevalier, A. (1946). Sur diverses Légumineuses Caesalpiniées à feuilles multi et parvifoliolées vivant dans les forêts d’Afrique tropicale et donnant des bois recherchés. Journal d’agriculture traditionnelle et de botanique appliquée, 26(289), 587-590. |

| ↑3 | de la Estrella, M., Forest, F., Klitgård, B., Lewis, G. P., Mackinder, B. A., de Queiroz, L. P., Wieringa, J. J., & Bruneau, A. (2018). A new phylogeny-based tribal classification of subfamily Detarioideae, an early branching clade of florally diverse tropical arborescent legumes. Scientific reports, 8(1), 6884. |

| ↑4 | de la Estrella, M., Forest, F., Klitgård, B., Lewis, G. P., Mackinder, B. A., de Queiroz, L. P., Wieringa, J. J., & Bruneau, A. (2018). A new phylogeny-based tribal classification of subfamily Detarioideae, an early branching clade of florally diverse tropical arborescent legumes. Scientific reports, 8(1), 6884. |

You’ve GOT to have a glass top cut for these tabletops, it’s be such a shame to mar it’s beauty..

Can anyone help me identify this wood? It’s solid wood about 1-1/2” thick. I’m assuming it’s zebra wood but haven’t seen any for sale in this large of size in phoenix, AZ so maybe it’s an imported piece? It’s custom with no markings so I’m at a loss figuring out what wood it is. It appears to have pretty open pores even with the existing finish on it.

I recently completed this keepsake box. It featured on Craftisian.com

It very difficult to work with for me.

My Dean Exotica Zebra ABG

I’d love to grow a pair of trees in the Oregon valley. Any recommendations on credible sources for seeds it starts?

Greeting from the Central Canada Tundra! I just completed this brown bear finished with Tru Oil. He is 8″L x 5″H x 3″W. Zebrawood is a pleasure to rotary-carve with. It does not burn like Purpleheart or Bubinga and the grain is outstanding from most of the board. Thanks for all the work you do to help us users of exotic and rare woods!

I’ve started work on a “Zebrawood” guitar kit (https://www.badcatinstruments.com/guitar-kit/p/electric-guitar-kit-solid-zebrawood-builder-kit-sg-style) and was hoping someone could take a look to see if it is, in fact, Microberlinia brazzavillensis (from what they’ve seen) or a different species (I’ve read through the wikipedia article as well explaining some of the alternative species). It’s super dense & has some relatively open pores but before I started grain filling/sealing I was hoping to get a confirmation of what I was working with. My plan is to go with a clear grain filler & do a sunburst stain over that, and I’ve gotten a couple blanks as… Read more »

Your two blanks look like the real deal. The guitar body/neck however, do not.

Ah k, thanks for the confirmation.

Be careful…there are tons of guitar necks and bodies on Ebay, for example, coming out of China that are absolutely NOT zebrawood, but are painted/manipulated to resemble it–in a very exaggerated way. That is the stripes are too solid black, too bold etc. The real deal will look a lot more subtle and naturally variable than that guitar blank.

I have put together a Bad Cat “zebrawood” guitar as well, upon further research into it I found that it is made of bakelite and is not wood at all. I wasn’t too mad about it as their website does actually list it as being made of bakelite and I did find this out before my purchase.

A low stool

Very Nice!

Does anybody else is eyes get irritated while cutting zebrano?

A turned platter from zebrawood.

How best to clean zebra wood?

Here Zebrawood is used to good effect In the back and sides of a Dowina Marus acoustic guitar.

HAve you noticed what aspects zebrawood add to the overall tonality?

I would say no. The back and sides of the guitar I mentioned are laminated so I think they add very little if anything to the tone. It is more of an aesthetic thing. It just looks great :)

They aren’t kidding when they talk about a characteristic unpleasant odor. Brings to mind a cat box that should have been changed a week ago.

Hi,

Firstly, thanks for such an informative website.

I’m making a knife handle out of unstabilised zebrano and wondering how to finish it.

Any recommendations for a sealant etc would be much appreciated.

thanks,

Phil

If you are going for a smooth, non-porous look, I’ve used CA glue to fill the pores with good success. The issue with most other pore fillers is that they are non-transparent, so you either have to try to match the lighter areas, or the darker areas, so one of the two will look a little bit off IMO.

bought some zebrawood from rockler to use for a box. came to me warped. how to flatten without trying to resurface with jointer or planer?

A belt sander (or bench sander) with a course grit.

I’ve had too many experiences with warped woods from Rocker. Won’t order from them anymore.

Little late now, but next time send it back for a nicer piece. You shouldn’t have to mill a board that much when you buy it from a place like Rockler or Woodcraft. If it’s warped slightly, you can wet a towel and lay it on the concave side for an hour or so.

I have a piece of Zebrawood 1 3/8 ^2 x 51 inch. There are two crossgrain ‘fractures’ that don’t go all the way through. Is this common in this wood? Do you think the strength of the wood is seriously compromised? Would there be any benefit in putting hot, thinned hide glue into the fracture? In use the wood will be horizontal and weighted 35lbs at each end, supported in the middle. I feel that may be ideal conditions if i wanted it to break, which alas, I don’t.

I seem to remmeber at least one of these “fractures” that you describe in a piece of zebrawood I had worked with, but no idea how common it is. I’d say it defeinitely affects the strength, but that will depend on how deep the openings go into the wood. Zebrawood is a pretty strong wood, so it may not be enough to be a problem. You might try putting some weight on it with your hand right at the fracture point and get a gut-level evaluation of how much flex/give there is at the weakest point. Perhaps thin CA glue… Read more »

Thank you for your response, and thoughts. Sometimes just explaining something to someone is enough to reveal to one the answer that is already known. The fractures were enough of a concern that the only right thing to do was to cut another piece from the original slab that doesn’t have fractures. Which I did. Now the whole thing is put together, and it was the only right choice. I then cut the other piece up at the fractures, and will use them in some other project.

Roger,

The cross grain fracture is caused when they are felling the tree. These trees are quite tall and when they fall it stresses the tree causing these cross grain fractures. This is quite common in these dense hard wood tress.

I have a slice of this zebrano wood out of which I would like to make a kitchen work top saver. Cutting vege or bread. Can i ask everyone’s opinions please. I also have another question for you knowledgeable people, Nyatta hardwood, I got my dad a new bench for his birthday, advertised as Nyatta. But I can’t find it on any wood data base. Help please in identifying this woods origin and future care. Many thanks Sarah.https://www.gardensandhomesdirect.co.uk/balmoral-hardwood-companion-garden-bench.html

This wood is very beautiful, it is used for many workmanships, in Europe also for fashion accessories.

The important thing is to preserve the natural forests, and to buy it only from areas of cultivation of wood!

Wow, Very Cool!

This true. My piece of zebra came from the Rocker Wood working store scrap bin.

That’s a mighty fine watch you have there.

Just got this supposed Zebrawood watch, made by Joycoast. Do you think this is genuine Zebrawood? Either way – it is definitely real wood, lightweight, and unique.

Looks genuine to me.

Im wondering if anyone has advice for repairing or restoring zebrawood with water damage. Love this table, but over time and a recent leak has been damaged. Hoping it can be repaired

It looks like the damage is, for the most part, only “skin deep” — meaning that the discoloration is occurring in the layer of finish on top of the wood, and not in the wood itself. It looks extensive enough that it’d be best to just strip/sand the finish completely off and refinish it. The quality of the finished product will be determined by your skill in wood finishing. Also, if it is veneer and not solid wood, you should be extremely careful not to sand through the layer of veneer, which would basically be irreparable (short of re-veneering the… Read more »

Thanks for that analysis and explanation. I believe it is veneer so I think I will follow my gut and get a professional involved :)

Front & Back of REAL Zebrawood SG Style (With matching pickguard from the area on the plank no less, matches pattern.)made for me by a Chinese Company i Don’t know if I can mention them or not… I’ll place the bridge myself. It’s unfinished… I’ll sand & seal it, toss in 3HHH 4DPDT & a 6way switch… then i’ll turn it up to 11.

If the term “Zebrawood” is used in the absolutely loosest sense — meaning wood that has zebra-like stripes — then yes, that could be called “Zebrawood.” But I’m about 99% sure that that guitar is NOT the Zebrawood that is being referred to on this page, Microberlinia brazzavillensis. Besides the color and pattern being off, true Zebrawood in the Microberlinia genus has large open pores that are quite noticeable and give it a unique texture. Even if the pores have been filled, a transparent pore filler would have to be used because of the two-toned nature of the wood, and… Read more »

The pores were very pronounced upon cleaning. We were talking about filling and what-knot….

I suppose I should tell people “It’s made of ‘Not Zebrawood’…”

Yea. …that will sell really well….

Especially when they ask “How knotty is it, duh-huh…”

I’ll send them this way for further explaination.

I would bet my entire wood stash… That is not “real” zeberawood. I have handled thousands of board feet of the stuff. That is defiantly some kind of dyed laminated man made product. Probably made from layers of birch or something similar.

Wouldn’t birch laminate be significantly heavier? These bodies are comparable in weight to ash and alder. And zebrano is less expensive than sitka spruce and wenge and mahogany. And mahogany is standard even in cheap Chinese Epiphones. I don’t see why the assumption would be that this is NOT zebra wood. Especially since this is China we’re talking about. China doesn’t care what you import and they don’t care about sustainable forestry. And they pay lumberjacks less than $10 a day.

Can anyone identify this wood type? I was told it was zebrawood but its clearly not. Orange stripes on dark dense wood. Cheers

Possibly Macassar Ebony? That almost looks too perfect to the point that it looks borderline fake! Is there a glue joint in the middle?

Hi I think your right ,some type of fake plastic -acrylic maybe. I was told it was real wood. One piece no joint

Well, you could try sanding inside one of those cavities and probably tell if it’s real sawdust, or just plastic…

I just did sand in a spot and its definitly real wood. Im getting wood dust for sure. Does Not have the dog smell of zebrawood tho. Very cool wood!

You, sir, have a member of the brachystecia family. Which one in particular, I can’t tell without a better res picture. I’m inclined to say zebrano (which, contrary to what this site says, is not the same wood even though it is routinely marketed as zebrawood), but I can’t be certain.

It’s a fine piece, whatever type it is. You’ve got quite the find.

The term zebra wood has been used for three different species. Check on wikipidia

It’s a beautifully dyed piece of plywood. Looks fantastic!

My custom made Zebra wood horse bow from Attila’s Archery.

I just found some zebra wood scales in an old box and it has a slight bow in it. What is the best way to straighten the scales before I start my next knife

try Hardwood Lumber & Millwork in Lakeland, FL

Just used some of this for a knife project…sands well and I don’t mind the open pores. Coated with wipe-on poly:

[url [/img][/url]

[/img][/url] [/img][/url]

[/img][/url]

[url

I am also using zebrawood scales for a knife handle. Now that I see yours, I will have to be patient and do it right. I do not want to rush and ruin it. Did you use linseed oil on it? I sometimes use a clear acrylic on handles, but for this blade linseed oil may be what I will use.

I used Minwax Wipe-on Poly in clear satin. Just wiped it on about 10+times, (not really paying attention to the directions) every couple hours if it seemed dry enough. Used a cotton swab for the nooks and crannies, and just kept the rag in a ziploc bag. Worked out really well, although I’m sure you could use linseed or tung oil. I just wanted a little more water resistance, and the poly goes on in such thin coats it really brings out the wood grain. Good luck with your knife project!

I make handcrafted cajons. The look of this wood gives a great contrast

to a lot of other woods. I like to use this wood for the head of the

drum. The head of these drums are planed down to 1/8″ thick. It does

tear out badly! Usually at the ends. I have also made a full body cajon

of this wood. The sound quality of this drum is amazing. I really like

this wood.

Can someone help me, I am looking for a good wood filler for Zebra Wood.

I enjoy making things from this lumber, but find that after much time

of sanding the end grain holds a pore finish, any brand or store that

sells wood filler and finish for Zebra Wood be great thanks

Chris, I’ve used CA glue as a pore filler on small pieces of Zebrawood in the past. The problem is that by its very nature the wood is two distinct tones, so the filler would have to be transparent, thus ruling out most commercial pore fillers.

Epoxy would work, no?

I’ve not used epoxy as a pore filler, but I think it could work in theory. When it comes to using products for uses other than their original intent, there’s a lot of trial and error to get the technique(s) just right.

I used it on some Mesquite I was working on as a test. One was a five minute, the other some T88 by System Three it works almost too well. The T88 is designed for oily woods and is my go to for stuff like cocobolo and Ebony. It has around an hour and a half set time. So you can do quite a lot of a piece in that time. To fill grain. The five minute, I would t do more than a 3”-4” square at a time. I had to use a little more force to make sure… Read more »

Epoxy goes yellow and cracks with age like polyurethane, no?

I make handcrafted cajons. The look of this wood gives a great contrast to a lot of other woods. I like to use this wood for the head of the drum. The head of these drums are planed down to 1/8″ thick. It does tear out badly! Usually at the ends. I have also made a full body cajon of this wood. The sound quality of this drum is amazing. I really like this wood.

Zebrawood is dense, hard, and beautiful. It doesn’t need to be heavily finished for the grain to dazzle. I have made few things with it, but nothing too great. I do have a friend who has been making wood sunglasses out of zebrawood for sometime now. He says it is the perfect wood because it is so hard… he’s been trying to get me to buy a pair from him

Recently built a table with zebrawood inlay. This required a large amount of sanding. Halfway through I developed a severe hayfever like allergy and could not wor for 2 days despite wearing a dusk mask.

Built a 63 foot bar top for a restaurant in Madison WI out of Zebrawood. Throughout the process of sanding, cutting, etc… a lot of people around the bar top had bad allergic reactions to the dust and shavings. I was sick for a week

Can someone help me, I am looking for a good wood filler for Zebra Wood. I enjoy making things from this lumber, but find that after much time of sanding the end grain holds a pore finish, any brand or store that sells wood filler and finish for Zebra Wood be great thanks

Chris

Well, I am certainly no expert of African geography, but according to most sources I’ve read it appears that Zebrawood (aka Zebrano) is indeed found in Cameroon, and is called there by the name: “Allen ele”.

The only other information I could gather about its whereabouts is this: “gregarious, sometimes in pure stands along riverbanks” according to Martin Chudnoff’s book, “Tropical Timbers of the World.”

Hi sir ,

i wish just to know if the wood zebrano is found in cameroon . if possible where in cameroon in which part o the country.

thanks

Well, I am certainly no expert of African geography, but according to most sources I’ve read it appears that Zebrawood (aka Zebrano) is indeed found in Cameroon, and is called there by the name: “Allen ele”.

The only other information I could gather about its whereabouts is this: “gregarious, sometimes in pure stands along riverbanks” according to Martin Chudnoff’s book, “Tropical Timbers of the World.”