by Eric Meier

First off, a few brief disclaimers:

- Aside from a few archery classes I took back in in college, I am neither an archer nor a bowyer.

- The ideas presented here would apply only to simple or self bows made from a single piece of wood, and may or may not be directly applicable to other types of bows such as composite or laminated bows.

With that being said, I have access to consolidated data on a lot of different kinds of wood. While there are almost endless ways to measure wood strength (which I discuss in more detail in my article World’s Strongest Woods), when you broaden the scope out to all woods worldwide, there are three tests that seem to come up most often. Listed in order of their commonness, they are: modulus of elasticity (MOE), modulus of rupture (MOR), and crushing strength. Of the three, we will be looking more closely at the first two tests.

Cracking the Code

Archery bows present a somewhat unique challenge in finding the right requirements for the best wood. In the simplest and crudest terms possible, the wood should be able to bend, but not break.

“As a rule of thumb, the best bow materials are those that combine a high specific bending strength with a relatively low specific modulus (Hickman et al. 1947). In general, a good bow is one to which a high force can be applied under a large elastic deformation, which guarantees that a large amount of elastic energy stored during the draw is transferred effectively into kinetic energy of the arrow when the bowstring is released.”[1]Bjurhager, I., Gamstedt, E., Keunecke, D., Niemz, P. & Berglund, L. (2013). Mechanical performance of yew (Taxus baccata L.) from a longbow perspective. Holzforschung, 67(7), 763.

To summarize the above recommendations, the authors call for a wood with “high specific bending strength” (MOR) along with a “relatively low specific modulus” (MOE).

Dealing in the simplest terms:

- The modulus of rupture (MOR) measures how easily the wood will break—the higher the number, the harder it is to break or rupture.

- The modulus of elasticity (MOE) measures how easily a wood will bend—the higher the number, the more stubborn and stiff it will be.

So in terms of looking at the raw mechanical data of woods, the best bow woods tend to be those that have a low MOE and a high MOR. Stated another way, the best bow woods tend to be those that will bend easily, and not break. This is perhaps an oversimplification, but it is at least a good starting point in evaluating new woods for suitability to use as an archery bow.

Creating a “Bow Index”

Instead of displaying the absolute values of each wood species, I thought it would be an interesting pursuit to come up with a ratio that compares the two pertinent values, MOR and MOE. This would in effect emphasize those woods with the special properties of having a disproportionately high MOR and/or a low MOE.

Given the rationale and requirements, an equation can be formed to roughly assess a wood’s suitability for bow use:

(MOR/MOE) * 1000.

(The added factor of 1000 is simply to bring the number to a more manageable size and avoid dealing with tiny .00XX decimal values.)

For lack of a better term, this ratio will simply be referred to as the wood’s “bow index.” Results are listed in the table below, sorted from highest to lowest bow index.

Bow Index Listing

| Bow Index | Common Name | Scientific Name |

|---|---|---|

| 13.06 | Iron birch | Betula schmidtii |

| 12.61 | Pear Hawthorn | Crataegus calpodendron |

| 11.90 | African Blackwood | Dalbergia melanoxylon |

| 11.61 | Rowan | Sorbus aucuparia |

| 11.61 | Lebombo ironwood | Androstachys johnsonii |

| 11.32 | Verawood | Bulnesia arborea |

| 11.27 | Pau Ferro | Machaerium spp. |

| 11.26 | Pacific Yew | Taxus brevifolia |

| 11.25 | Muninga | Pterocarpus angolensis |

| 11.15 | Tropical black sage | Cordia curassavica |

| 11.05 | Osage orange | Maclura pomifera |

| 10.98 | River Sheoak | Casuarina cunninghamiana |

| 10.90 | Guajayvi | Patagonula americana |

| 10.85 | Chinaberry | Melia azedarach |

| 10.85 | Norway maple | Acer platanoides |

| 10.72 | Jutahy | Dialium guianense |

| 10.68 | Pear | Pyrus communis |

| 10.57 | Mansonia | Mansonia altissima |

| 10.57 | Turkey Oak | Quercus cerris |

| 10.57 | Movingui | Distemonanthus benthamianus |

| 10.52 | Pau Santo | Zollernia paraensis |

| 10.52 | Makore | Tieghemella heckelii |

| 10.50 | Bur Oak | Quercus macrocarpa |

| 10.49 | River Red Gum | Eucalyptus camaldulensis |

| 10.47 | Preciosa | Aniba canelilla |

| 10.47 | Western sheoak | Allocasuarina fraseriana |

| 10.44 | Siamese Rosewood | Dalbergia cochinchinensis |

| 10.42 | Field maple | Acer campestre |

| 10.40 | Monterey Cypress | Cupressus macrocarpa |

| 10.37 | Algarrobo Blanco | Prosopis alba |

| 10.36 | Etimoe | Copaifera salikounda |

| 10.35 | Ziricote | Cordia dodecandra |

| 10.31 | Ekki | Lophira alata |

| 10.31 | English Walnut | Juglans regia |

| 10.31 | Alligator Juniper | Juniperus deppeana |

| 10.22 | Brazilwood | Paubrasilia echinata |

| 10.18 | Downy Birch | Betula pubescens |

| 10.08 | Crab apple | Malus sylvestris |

| 10.08 | Tambootie | Spirostachys africana |

| 10.04 | Black Mesquite | Prosopis nigra |

| 10.01 | Curupay | Anadenanthera colubrina |

| 10.00 | Eastern Red Cedar | Juniperus virginiana |

| 10.00 | Rough-barked apple | Angophora floribunda |

| 9.98 | Ceylon Satinwood | Chloroxylon swietenia |

| 9.94 | East Indian Rosewood | Dalbergia latifolia |

| 9.93 | Rhodesian Teak | Baikiaea plurijuga |

| 9.90 | African Padauk | Pterocarpus soyauxii |

| 9.89 | Sycamore maple | Acer pseudoplatanus |

| 9.86 | Peruvian Walnut | Juglans neotropica |

| 9.86 | Blue Ash | Fraxinus quadrangulata |

| 9.84 | Ebiara | Berlinia spp. |

| 9.82 | Burma Padauk | Pterocarpus macrocarpus |

| 9.80 | Sweet Cherry | Prunus avium |

| 9.76 | Nutmeg Hickory | Carya myristiciformis |

| 9.74 | Siberian Elm | Ulmus pumila |

| 9.72 | Pau Rosa | Bobgunnia fistuloides |

| 9.72 | Pau Rosa | Bobgunnia madagascarensis |

| 9.69 | Brazilian Rosewood | Dalbergia nigra |

| 9.67 | Lemonwood | Calycophyllum candidissimum |

| 9.63 | American Hornbeam | Carpinus caroliniana |

| 9.62 | Turpentine | Syncarpia glomulifera |

| 9.62 | Moabi | Baillonella toxisperma |

| 9.61 | Rock Elm | Ulmus thomasii |

| 9.58 | Shellbark Hickory | Carya laciniosa |

| 9.56 | Chakte Kok | Simira salvadorensis |

| 9.55 | Bitternut Hickory | Carya cordiformis |

| 9.54 | Avodire | Turraeanthus africanus |

| 9.53 | European Yew | Taxus baccata |

| 9.52 | Prosopis juliflora | Prosopis juliflora |

| 9.50 | Malabayabas | Tristaniopsis decorticata |

| 9.49 | Afata | Cordia trichotoma |

| 9.46 | Black Locust | Robinia pseudoacacia |

| 9.46 | Nigerian pearwood | Guarea cedrata |

| 9.46 | Bosse | Guarea spp. |

| 9.44 | Horse chestnut | Aesculus hippocastanum |

| 9.43 | Saffronheart | Halfordia scleroxyloa |

| 9.40 | Congotali | Letestua durissima |

| 9.39 | Bocote | Cordia elaeagnoides |

| 9.38 | Southern Silky Oak | Grevillea robusta |

| 9.38 | Sissoo | Dalbergia sissoo |

| 9.37 | African Mesquite | Prosopis africana |

| 9.37 | Quina | Myroxylon peruiferum |

| 9.36 | Oregon White Oak | Quercus garryana |

| 9.36 | Gaboon Ebony | Diospyros crassiflora |

| 9.35 | Shagbark Hickory | Carya ovata |

| 9.34 | Oregon Ash | Fraxinus latifolia |

| 9.34 | Iroko | Milicia excelsa |

| 9.29 | Live Oak | Quercus virginiana |

| 9.28 | Holly | Ilex opaca |

| 9.28 | Sessile Oak | Quercus petraea |

| 9.28 | Chanfuta | Afzelia quanzensis |

| 9.25 | Yellow Gum | Eucalyptus leucoxylon |

| 9.25 | Grey myrtle | Backhousia myrtifolia |

| 9.24 | Hackberry | Celtis occidentalis |

| 9.21 | Texas Ebony | Ebenopsis ebano |

| 9.19 | Bekak | Aglaia lawii |

| 9.18 | Machiche | Lonchocarpus spp. |

| 9.17 | Shittim | Vachellia seyal |

| 9.14 | Bubinga | Guibourtia spp. |

| 9.14 | African Walnut | Lovoa trichilioides |

| 9.14 | Japanese Larch | Larix kaempferi |

| 9.14 | Ceylon Ebony | Diospyros ebenum |

| 9.13 | English Elm | Ulmus procera |

| 9.13 | Dutch Elm | Ulmus x hollandica |

| 9.13 | Pink Ivory | Berchemia zeyheri |

| 9.12 | Sapele | Entandrophragma cylindricum |

| 9.12 | European Hornbeam | Carpinus betulus |

| 9.12 | Cedar Elm | Ulmus crassifolia |

| 9.12 | English Oak | Quercus robur |

| 9.12 | Merbau | Intsia bijuga |

| 9.10 | Scarlet Oak | Quercus coccinea |

| 9.09 | Obeche | Triplochiton scleroxylon |

| 9.06 | Amazon Rosewood | Dalbergia spruceana |

| 9.06 | Santos Mahogany | Myroxylon balsamum |

| 9.06 | Cascara Buckthorn | Rhamnus purshiana |

| 9.06 | Macassar Ebony | Diospyros celebica |

| 9.06 | Argentine Osage Orange | Maclura tinctoria |

| 9.05 | Tamo Ash | Fraxinus mandshurica |

| 9.03 | Primavera | Roseodendron donnell-smithii |

| 9.03 | Yucatan Rosewood | Dalbergia tucurensis |

| 9.02 | Chico Zapote | Manilkara zapota |

| 9.02 | Honey Locust | Gleditsia triacanthos |

| 9.02 | Pyinma | Lagerstroemia spp. |

| 8.99 | Canadian Serviceberry | Amelanchier canadensis |

| 8.97 | Winged Elm | Ulmus alata |

| 8.91 | Urundeuva | Astronium urundeuva |

| 8.91 | Utile | Entandrophragma utile |

| 8.91 | Amendoim | Pterogyne nitens |

| 8.89 | Pignut Hickory | Carya glabra |

| 8.88 | Afzelia xylay | Afzelia xylocarpa |

| 8.87 | Overcup Oak | Quercus lyrata |

| 8.87 | Mangium | Acacia mangium |

| 8.86 | Idigbo | Terminalia ivorensis |

| 8.85 | Okoume / Gaboon | Aucoumea klaineana |

| 8.85 | Itin | Prosopis kuntzei |

| 8.84 | Black Poplar | Populus nigra |

| 8.83 | Gidgee | Acacia cambagei |

| 8.82 | Black Palm | Borassus flabellifer |

| 8.82 | Wych Elm | Ulmus glabra |

| 8.82 | Imbuya | Ocotea porosa |

| 8.82 | Canarywood | Centrolobium spp. |

| 8.81 | Water Hickory | Carya aquatica |

| 8.81 | American Elm | Ulmus americana |

| 8.81 | Persimmon | Diospyros virginiana |

| 8.80 | Queensland Walnut | Endiandra palmerstonii |

| 8.80 | Longhi | Chrysophyllum africanum |

| 8.79 | California Black Oak | Quercus kelloggii |

| 8.78 | Opepe | Nauclea diderrichii |

| 8.76 | Mexican Cypress | Cupressus lusitanica |

| 8.74 | East African Olive | Olea capensis |

| 8.74 | Post Oak | Quercus stellata |

| 8.74 | Pumpkin Ash | Fraxinus profunda |

| 8.73 | Koto | Pterygota macrocarpa |

| 8.72 | Red Elm | Ulmus rubra |

| 8.72 | Endra endra | Humbertia madagascariensis |

| 8.71 | Yellow Box | Eucalyptus melliodora |

| 8.70 | Afrormosia | Pericopsis elata |

| 8.70 | Dogwood | Cornus florida |

| 8.69 | Black Walnut | Juglans nigra |

| 8.67 | Plum | Prunus domestica |

| 8.66 | American Beech | Fagus grandifolia |

| 8.65 | Mockernut Hickory | Carya tomentosa |

| 8.65 | Mountain Hemlock | Tsuga mertensiana |

| 8.64 | Red Mulberry | Morus rubra |

| 8.64 | Paulownia | Paulownia spp. |

| 8.63 | Hard maple | Acer saccharum |

| 8.63 | Giant Chinkapin | Chrysolepis chrysophylla |

| 8.62 | Wenge | Millettia laurentii |

| 8.62 | Mopane | Colophospermum mopane |

| 8.62 | White Ash | Fraxinus americana |

| 8.62 | White Meranti | Shorea hypochra |

| 8.60 | Lati | Amphimas pterocarpoides |

| 8.58 | African Mahogany | Khaya senegalensis |

| 8.58 | Swamp White Oak | Quercus bicolor |

| 8.57 | Staghorn Sumac | Rhus typhina |

| 8.55 | Maritime Pine | Pinus pinaster |

| 8.55 | Virginia Pine | Pinus virginiana |

| 8.55 | White Cypress Pine | Callitris columellaris |

| 8.54 | Swamp Mahogany | Eucalyptus robusta |

| 8.54 | Asepoko | Pouteria guianensis |

| 8.53 | Quebracho | Schinopsis quebracho |

| 8.52 | Monkeythorn | Senegalia galpinii |

| 8.52 | Gray Birch | Betula populifolia |

| 8.51 | Pintobortri | Pouteria eugenifolia |

| 8.49 | Green Ash | Fraxinus pennsylvanica |

| 8.48 | Abura | Mitragyna ciliata |

| 8.47 | Afzelia | Afzelia spp. |

| 8.46 | Madrone | Arbutus menziesii |

| 8.45 | Mangkono | Xanthostemon verdugonianus |

| 8.45 | Cocobolo | Dalbergia retusa |

| 8.45 | Brown Ebony | Libidibia paraguariensis |

| 8.44 | Mediterranean Cypress | Cupressus sempervirens |

| 8.44 | Brownheart | Vouacapoua americana |

| 8.43 | Grey Box | Eucalyptus moluccana |

| 8.43 | Suriname Ironwood | Bocoa prouacensis |

| 8.42 | Andaman Padauk | Pterocarpus dalbergioides |

| 8.42 | White Oak | Quercus alba |

| 8.41 | European Ash | Fraxinus excelsior |

| 8.40 | Amourette (snakewood sapwood) | Brosimum guianense |

| 8.40 | Snakewood | Brosimum guianense |

| 8.40 | Boxwood | Buxus sempervirens |

| 8.40 | Mgurure | Combretum schumannii |

| 8.39 | Koa | Acacia koa |

| 8.39 | Bloodwood | Brosimum rubescens |

| 8.39 | Tamarind | Tamarindus indica |

| 8.39 | London plane FS | Platanus x acerifolia |

| 8.39 | London plane QS | Platanus x acerifolia |

| 8.37 | Beli | Julbernardia pellegriniana |

| 8.36 | Chestnut Oak | Quercus prinus |

| 8.36 | Monkey pot | Lecythis zabucajo |

| 8.35 | Lyptus | Eucalyptus urograndis |

| 8.34 | Black wattle | Acacia mearnsii |

| 8.34 | Panga Panga | Millettia stuhlmannii |

| 8.33 | Bulletwood | Manilkara bidentata |

| 8.32 | Tineo | Weinmannia trichosperma |

| 8.32 | Cape Holly | Ilex mitis |

| 8.32 | Monkey Puzzle | Araucaria araucana |

| 8.31 | Black Oak | Quercus velutina |

| 8.31 | European alder | Alnus glutinosa |

| 8.30 | Monkeypod | Samanea saman |

| 8.30 | Sweet Chestnut | Castanea sativa |

| 8.29 | Eastern Hophornbeam | Ostrya virginiana |

| 8.29 | River Birch | Betula nigra |

| 8.28 | Shumard Oak | Quercus shumardii |

| 8.27 | Scots Pine (R) | Pinus sylvestris |

| 8.27 | Huon Pine | Lagarostrobos franklinii |

| 8.26 | Gum Arabic | Vachellia nilotica |

| 8.26 | Yellow Birch | Betula alleghaniensis |

| 8.26 | Parica | Schizolobium amazonicum |

| 8.26 | Black Cherry | Prunus serotina |

| 8.25 | Horsetail Casuarina | Casuarina equisetifolia |

| 8.25 | Smooth-barked apple | Angophora costata |

| 8.24 | Willow Oak | Quercus phellos |

| 8.23 | Slash Pine | Pinus elliottii |

| 8.23 | Sand Pine | Pinus clausa |

| 8.23 | Limba | Terminalia superba |

| 8.22 | Sneezewood | Ptaeroxylon obliquum |

| 8.21 | Black maple | Acer nigrum |

| 8.21 | Garapa | Apuleia leiocarpa |

| 8.21 | Queensland kauri | Agathis robusta |

| 8.20 | Jatoba | Hymenaea courbaril |

| 8.19 | Mutenye | Guibourtia arnoldiana |

| 8.19 | Black siris | Albizia odoratissima |

| 8.19 | Silver Birch | Betula pendula |

| 8.17 | Lancewood | Oxandra lanceolata |

| 8.17 | Red maple | Acer rubrum |

| 8.17 | Water Oak | Quercus nigra |

| 8.17 | Red Oak | Quercus rubra |

| 8.16 | Crack Willow | Salix fragilis |

| 8.14 | Pericopsis | Pericopsis mooniana |

| 8.14 | Indian Laurel | Terminalia elliptica |

| 8.14 | Southern Red Oak | Quercus falcata |

| 8.13 | Grey Ironbark | Eucalyptus paniculata |

| 8.13 | Northern White Cedar | Thuja occidentalis |

| 8.12 | Parana Pine | Araucaria angustifolia |

| 8.12 | Cedar of Lebanon | Cedrus libani |

| 8.10 | Narra | Pterocarpus indicus |

| 8.09 | Pin Oak | Quercus palustris |

| 8.08 | Mora (glued) | Mora excelsa |

| 8.08 | Mora | Mora gonggrijpii |

| 8.07 | Lemon-Scented Gum | Corymbia citriodora |

| 8.06 | Ramin | Gonystylus spp. |

| 8.06 | Wamara | Swartzia benthamiana |

| 8.06 | Nargusta | Terminalia amazonia |

| 8.05 | Ohia | Metrosideros collina |

| 8.04 | Tanoak | Notholithocarpus densiflorus |

| 8.04 | Sassafras | Sassafras albidum |

| 8.03 | Southern Redcedar | Juniperus silicicola |

| 8.03 | Honduran Mahogany | Swietenia macrophylla |

| 8.02 | Angelim vermelho | Dinizia excelsa |

| 8.02 | Ipe | Handroanthus serratifolius |

| 8.01 | Purpleheart | Peltogyne spp. |

| 8.00 | Black Tupelo | Nyssa sylvatica |

| 8.00 | Southern Magnolia | Magnolia grandiflora |

| 7.99 | European silver fir | Abies alba |

| 7.99 | Laurel Oak | Quercus laurifolia |

| 7.99 | Cuban Mahogany | Swietenia mahogani |

| 7.98 | Hububali | Loxopterygium sagotii |

| 7.97 | Blackheart Sassafras | Atherosperma moschatum |

| 7.97 | African Juniper | Juniperus procera |

| 7.94 | Cherrybark Oak | Quercus pagoda |

| 7.93 | Kaneelhart | Licaria canella |

| 7.93 | Andiroba | Carapa spp. |

| 7.92 | Rubberwood | Hevea brasiliensis |

| 7.92 | Pecan | Carya illinoinensis |

| 7.92 | Myrtle | Umbellularia californica |

| 7.91 | Greenheart | Chlorocardium rodiei |

| 7.90 | Teak | Tectona grandis |

| 7.88 | Black Ash | Fraxinus nigra |

| 7.87 | Radiata Pine | Pinus radiata |

| 7.87 | Pheasantwood | Senna siamea |

| 7.86 | Messmate | Eucalyptus obliqua |

| 7.86 | Patula Pine | Pinus patula |

| 7.85 | Swamp Chestnut Oak | Quercus michauxii |

| 7.84 | Cumaru | Dipteryx odorata |

| 7.84 | Red Palm | Cocos nucifera |

| 7.82 | Yellow Cedar | Cupressus nootkatensis |

| 7.81 | Peroba Rosa | Aspidosperma polyneuron |

| 7.81 | Silver maple | Acer saccharinum |

| 7.80 | Tiete Rosewood | Guibourtia hymenaeifolia |

| 7.79 | Sweet Birch | Betula lenta |

| 7.78 | Limber Pine | Pinus flexilis |

| 7.78 | Tasmanian Myrtle | Lophozonia cunninghamii |

| 7.77 | Northern Catalpa | Catalpa speciosa |

| 7.76 | Spanish Cedar | Cedrela odorata |

| 7.76 | Australian Red Cedar | Toona ciliata |

| 7.74 | Paldao | Dracontomelon dao |

| 7.74 | Paper Birch | Betula papyrifera |

| 7.73 | Red Bloodwood | Corymbia gummifera |

| 7.72 | Black Willow | Salix nigra |

| 7.71 | Water Tupelo | Nyssa aquatica |

| 7.70 | European Beech | Fagus sylvatica |

| 7.69 | Incense Cedar | Calocedrus decurrens |

| 7.67 | Mango | Mangifera indica |

| 7.65 | Brazilian Pau Rosa | Aniba rosaeodora |

| 7.64 | Caribbean Pine | Pinus caribaea |

| 7.63 | Boxelder | Acer negundo |

| 7.63 | European Larch | Larix decidua |

| 7.62 | Sweetgum | Liquidambar styraciflua |

| 7.62 | Rose Gum | Eucalyptus grandis |

| 7.62 | Grey alder | Alnus incana |

| 7.59 | Hormigo Negro | Platymiscium dimorphandrum |

| 7.58 | West African albizia | Albizia ferruginea |

| 7.58 | Anigre | Pouteria altissima |

| 7.57 | Yellow Meranti | Shorea spp. |

| 7.56 | Belah | Casuarina cristata |

| 7.56 | Thuya | Tetraclinis articulata |

| 7.55 | Pitch Pine | Pinus rigida |

| 7.54 | New Guinea Walnut | Dracontomelon mangiferum |

| 7.54 | Pacific maple | Aglaia cucullata |

| 7.54 | Katalox | Swartzia cubensis |

| 7.54 | Eveuss | Klainedoxa gabonensis |

| 7.53 | Ovangkol | Guibourtia ehie |

| 7.53 | Sourwood | Oxydendrum arboreum |

| 7.50 | Jeffrey Pine | Pinus jeffreyi |

| 7.50 | Zebrawood | Microberlinia brazzavillensis |

| 7.49 | Shortleaf Pine | Pinus echinata |

| 7.48 | Queensland Maple | Flindersia brayleyana |

| 7.48 | Table Mountain Pine | Pinus pungens |

| 7.48 | Lebbeck | Albizia lebbeck |

| 7.47 | Port Orford Cedar | Chamaecyparis lawsoniana |

| 7.42 | Eastern Hemlock | Tsuga canadensis |

| 7.39 | Coffeetree | Gymnocladus dioicus |

| 7.38 | Bigleaf maple | Acer macrophyllum |

| 7.38 | Deglupta | Eucalyptus deglupta |

| 7.36 | Yellow silverballi | Aniba hypoglauca |

| 7.36 | Northern Silky Oak | Cardwellia sublimis |

| 7.36 | Cypress | Taxodium distichum |

| 7.34 | Jarrah | Eucalyptus marginata |

| 7.34 | Redwood | Sequoia sempervirens |

| 7.34 | Mexican alder | Alnus jorullensis |

| 7.33 | Jack Pine | Pinus banksiana |

| 7.33 | Spruce Pine | Pinus glabra |

| 7.32 | Longleaf Pine | Pinus palustris |

| 7.31 | Timborana | Pseudopiptadenia suaveolens |

| 7.31 | Atlantic White Cedar | Chamaecyparis thyoides |

| 7.31 | White Poplar | Populus alba |

| 7.30 | New Zealand kauri | Agathis australis |

| 7.30 | Dark Red Meranti | Shorea spp. |

| 7.29 | Common Lime | Tilia x europaea |

| 7.29 | Keruing | Dipterocarpus spp. |

| 7.29 | Ponderosa Pine | Pinus ponderosa |

| 7.27 | Alder-leaf Birch | Betula alnoides |

| 7.26 | Aromata | Clathrotropis macrocarpa |

| 7.25 | Araracanga | Aspidosperma megalocarpon |

| 7.25 | Rose sheoak | Allocasuarina torulosa |

| 7.25 | White Willow | Salix alba |

| 7.24 | Lignum Vitae | Guaiacum officinale |

| 7.22 | Hoop Pine | Araucaria cunninghamii |

| 7.22 | Balau | Shorea spp. |

| 7.20 | Angelique | Dicorynia guianensis |

| 7.20 | East Indian Kauri | Agathis dammara |

| 7.18 | Nyatoh | Palaquium spp. Payena spp. |

| 7.18 | Blue Gum | Eucalyptus globulus |

| 7.18 | Espave | Anacardium excelsum |

| 7.18 | Cheesewood | Alstonia congensis |

| 7.17 | Spotted Gum | Corymbia maculata |

| 7.16 | Alaska Paper Birch | Betula neoalaskana |

| 7.15 | Burmese Blackwood | Dalbergia cultrata |

| 7.15 | Marblewood | Zygia racemosa |

| 7.15 | Loblolly Pine | Pinus taeda |

| 7.13 | White Seraya | Parashorea spp. |

| 7.12 | Quaking Aspen | Populus tremuloides |

| 7.10 | Red alder | Alnus rubra |

| 7.10 | Khasi Pine | Pinus kesiya |

| 7.08 | Quipo | Cavanillesia platanifolia |

| 7.08 | Douglas-Fir | Pseudotsuga menziesii |

| 7.07 | Tamarack | Larix larcina |

| 7.07 | Goncalo Alves | Astronium graveolens |

| 7.05 | Siam balsa | Alstonia spatulata |

| 7.05 | Red ash | Alphitonia excelsa |

| 7.04 | Sycamore | Platanus occidentalis |

| 7.04 | Guanacaste | Enterolobium cyclocarpum |

| 7.03 | Raspberry jam | Acacia acuminata |

| 7.03 | Buloke | Allocasuarina luehmannii |

| 7.02 | Partridgewood | Andira inermis |

| 7.01 | Lodgepole Pine | Pinus contorta |

| 7.00 | Doi | Alphitonia zizyphoides |

| 6.99 | California red fir | Abies magnifica |

| 6.99 | American Chestnut | Castanea dentata |

| 6.99 | Australian blackwood | Acacia melanoxylon |

| 6.98 | Heavy hopea | Hopea iriana |

| 6.98 | Yarran | Acacia homalophylla |

| 6.97 | Yellowheart | Euxylophora paraensis |

| 6.96 | Camphor | Cinnamomum camphora |

| 6.95 | Western Larch | Larix occidentalis |

| 6.94 | Candlenut | Aleurites moluccanus |

| 6.94 | Eastern White Pine | Pinus strobus |

| 6.93 | Western Hemlock | Tsuga heterophylla |

| 6.89 | Mountain Ash | Eucalyptus regnans |

| 6.89 | Sugar Pine | Pinus lambertiana |

| 6.86 | Butternut | Juglans cinerea |

| 6.84 | Red Mangrove | Rhizophora mangle |

| 6.84 | Pinyon Pine | Pinus edulis |

| 6.84 | Rengas | Gluta spp. |

| 6.81 | Tree of Heaven | Ailanthus altissima |

| 6.81 | Norfolk Island Pine | Araucaria heterophylla |

| 6.79 | Light Red Meranti | Shorea contorta |

| 6.77 | Batai | Falcataria moluccana |

| 6.76 | Cucumbertree | Magnolia acuminata |

| 6.76 | Western Red Cedar | Thuja plicata |

| 6.75 | Red Pine | Pinus resinosa |

| 6.74 | Tzalam | Lysiloma latisiliquum |

| 6.71 | Boonaree | Alectryon oleifolius |

| 6.71 | Rock sheoak | Allocasuarina huegeliana |

| 6.71 | Beefwood | Grevillea striata |

| 6.70 | Salmwood | Cordia alliodora |

| 6.70 | Indian Silver Greywood | Terminalia bialata |

| 6.70 | Cerejeira | Amburana cearensis |

| 6.69 | Black Cottonwood | Populus trichocarpa |

| 6.69 | Pin Cherry | Prunus pensylvanica |

| 6.66 | Noble fir | Abies procera |

| 6.66 | Ocote Pine | Pinus oocarpa |

| 6.65 | Sweetbay | Magnolia virginiana |

| 6.64 | Western White Pine | Pinus monticola |

| 6.64 | Black Spruce | Picea mariana |

| 6.63 | Pond Pine | Pinus serotina |

| 6.59 | Indian pulai | Alstonia scholaris |

| 6.58 | Engelmann Spruce | Picea engelmannii |

| 6.57 | White Spruce | Picea glauca |

| 6.56 | Jelutong | Dyera costulata |

| 6.55 | Andean alder | Alnus acuminata |

| 6.53 | White fir | Abies concolor |

| 6.52 | Tatajuba | Bagassa guianensis |

| 6.49 | Norway Spruce | Picea abies |

| 6.48 | Coracao de negro | Swartzia panacoco |

| 6.47 | Sumatran Pine | Pinus merkusii |

| 6.41 | Yellow buckeye | Aesculus flava |

| 6.39 | Yellow poplar | Liriodendron tulipifera |

| 6.36 | Bigtooth Aspen | Populus grandidentata |

| 6.36 | European Aspen | Populus tremula |

| 6.36 | Subalpine fir | Abies lasiocarpa |

| 6.35 | Balsam fir | Abies balsamea |

| 6.34 | Sitka Spruce | Picea sitchensis |

| 6.27 | Hard milkwood | Alstonia spectabilis |

| 6.27 | Tornillo | Cedrelinga cateniformis |

| 6.25 | Karri | Eucalyptus diversicolor |

| 6.24 | Broad-leaved apple | Angophora subvelutina |

| 6.20 | Eastern Cottonwood | Populus deltoides |

| 6.18 | Balsam Poplar | Populus balsamifera |

| 6.18 | Manil montagne | Moronobea coccinea |

| 6.17 | Nepalese alder | Alnus nepalensis |

| 6.14 | Red Spruce | Picea rubens |

| 6.14 | Black Ironwood | Krugiodendron ferreum |

| 6.12 | Fijian kauri | Agathis macrophylla |

| 6.09 | Pacific silver fir | Abies amabilis |

| 6.05 | Pink ash | Alphitonia petriei |

| 5.99 | Chechen | Metopium brownei |

| 5.96 | Basswood | Tilia americana |

| 5.96 | Austrian Pine | Pinus nigra |

| 5.90 | Kempas | Koompassia malaccensis |

| 5.71 | Grand fir | Abies grandis |

| 5.28 | Balsa | Ochroma pyramidale |

| 4.76 | Sugi | Cryptomeria japonica |

A Closer Look at MOE and Wood Anatomy

Regardless of one’s feelings about the results of the bow index list above, it is almost universally recognized that modulus of elasticity (MOE) is a very important measurement for wood bows. After all, the very act of bending an archery bow has direct bearing on this measurement. But unlike wood hardness, which has been shown to have a very strong and predictable relation to wood density[2]Wiemann, M. C. (2007). Estimating Janka hardness from specific gravity for tropical and temperate species (Vol. 643). US Department of Agriculture, Forest Service, Forest Products Laboratory., MOE has shown much more of a variation with relation to a wood’s density. In short, there appears to be some woods that are heavy, where you’d expect them to be commensurately stiffer as well, but that’s not always the case. There appears to be at least one other factor in play in determining MOE.

Enter microfibrils.

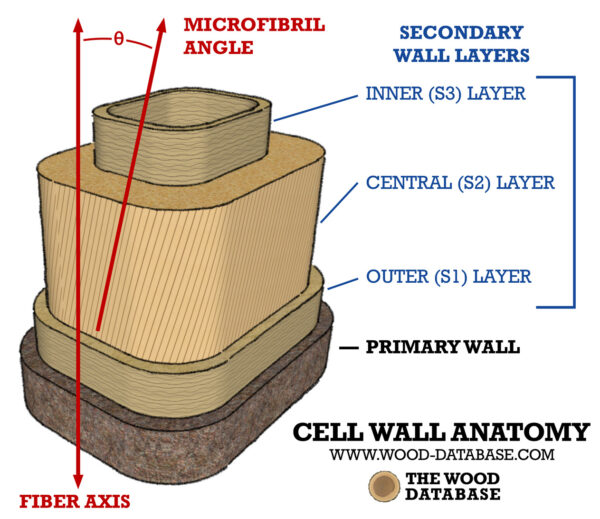

Microfibrils are tiny strands found within the cell walls of wood. Usually they run parallel with the wood grain, but that’s not always the case, and they can sometimes run at varying degrees off of parallel, which is called the microfibril angle (MFA). (See the notes in red lettering pertaining to the central S2 layer in the reference image below.)

Note this is not to be confused with interlocked or spiral grain found in some wood species, as microfibrils are much smaller—it’s possible to have a wood with straight grain but angled microfibrils.

It appears that the microfibril angle (MFA) is the hidden variable that accounts for (most) of the remaining variation in predicting MOE, since the value is so hard to predict if relying on wood density alone. In studying species of Eucalyptus, it was found that “MFA alone accounted for 87 percent of the variation in MOE, while density alone accounted for 81 percent. Together, MFA and density (as Density/MFA) accounted for 92 percent of the variation in MOE.”[3]Yang, J. L., & Evans, R. (2003). Prediction of MOE of eucalypt wood from microfibril angle and density. Holz als Roh-und Werkstoff, 61(6), 449-452. So an increased off-axis microfibril angle contributes to a decrease in MOE. (Specifically, the microfibril angle in the larger central S2 layer pictured above.[4]Donaldson, L. (2008). Microfibril angle: measurement, variation and relationships–a review. IAWA Journal, 29(4), 345-386.) But perhaps equally important, though easy to overlook, the same study found that “MFA had little independent influence on MOR.”[5]Yang, J. L., & Evans, R. (2003). Prediction of MOE of eucalypt wood from microfibril angle and density. Holz als Roh-und Werkstoff, 61(6), 449-452.

In practical terms, the microfibril angle acts as a special variable that allows otherwise dense and strong woods to have a disproportionately low MOE with no effect on the MOR. An increased density would also mean an increase in both MOE and MOR, which would have little to no effect on a wood’s bow index. But woods with a high MFA could have the peculiar combination of a high MOR and a low MOE, exactly what we’re hunting for.

Are you an aspiring wood nerd?

References[+]

| ↑1 | Bjurhager, I., Gamstedt, E., Keunecke, D., Niemz, P. & Berglund, L. (2013). Mechanical performance of yew (Taxus baccata L.) from a longbow perspective. Holzforschung, 67(7), 763. |

|---|---|

| ↑2 | Wiemann, M. C. (2007). Estimating Janka hardness from specific gravity for tropical and temperate species (Vol. 643). US Department of Agriculture, Forest Service, Forest Products Laboratory. |

| ↑3, ↑5 | Yang, J. L., & Evans, R. (2003). Prediction of MOE of eucalypt wood from microfibril angle and density. Holz als Roh-und Werkstoff, 61(6), 449-452. |

| ↑4 | Donaldson, L. (2008). Microfibril angle: measurement, variation and relationships–a review. IAWA Journal, 29(4), 345-386. |

All fine and good, and really interesting BUT, I’m a simple man looking for a simple answer. Based on THIS index am I to assume the higher the number the better the wood for bow making? I noticed that Osage Orange and two varieties of Yew were pretty high on the index which lead me to that assumption. Is that reasonably accurate?

From what I can tell, design also plays a crucial role. Bow wood like Osage Orange and Yew with a high rated index can be narrower and thicker, more like classic English bows, while low rated woods need to have wider, thinner, longer designs implemented to compensate for a low index. At least that is my understanding, that you can make bows from lower scoring woods but the design needs to be modified accordingly to compensate and as such have potential with those design considerations to preform similarly to other “classic” bow woods.

Thank you to the author for doing this research and making it available for us mere mortals.

I’d suggest evaluating the mechanical properties of the heartwood versus sapwood, in species of wood where the properties differ.

I assume the Compression side of the limb needs more compression strength.

Eric, thanks for a large helping of food for thought. I have been chewing on this off and on for years. As I search the web for more information, I find a lot of sites referring back here to Eric’s Bow Index. Eric, you made your mark. I am not an archer either, I was a materials engineer by trade, so this is interesting, but I’ll never build a bow. The bow index, 1000*(MOR/MOE) is 10 times the strain to failure as expressed in percentages. In other words, MOR/MOE is the strain to failure. So the index is a mechanical… Read more »

There is a typo in my spreadsheet in the fling speed numbers. The SI unit for density was inadvertently left in place when I tried to replaced it the imperial pounds per cubic foot. All of the fling speed numbers are wrong. For the heavier woods, the error is small, but for the high and low density materials the errors are proportionally larger. The correct numbers are: Wood Species . . self-fling speed v Yew . . . . . . . . . 141 Osage orange .. 133 Brazil wood . . .. 142 Madagascar Rosewood . . .… Read more »

Ive made a small recurve bow that is twisted spring steel rods as the core and pvc backing and i used high copper or brass alloy wire to wrap it with. So pvc =, horn. Spring steel rods= core. Wire = sinew. It shoots very fast and power ful and is hard to string alone even tho its only 18 inches or sometime. 9560 steel can bend 90 degrees and spring back with out being deformed. That would be the ultimate bow material i believe.