by Eric Meier

Within the massive Quercus genus, oak species are subdivided into a number of sections, though all commercially harvested New World oaks can be placed into one of two categories: red oak, or white oak. This division is based on the morphology of the trees themselves—for instance, red oaks have pointed lobes on the leaves, while white oaks have rounded lobes.

But in addition to the leaves and outward appearance of the trees, the wood of the various oaks also have a few important distinctions. Most notably, white oak is rot resistant, while red oak is not—an important detail for boatbuilding and exterior construction projects. White oak also has a unique ray fleck pattern when perfectly quartersawn that’s seen more often in antiques—a figure that’s sometimes called “tiger oak” in antique furniture circles.

It should be noted that red oak also has conspicuous ray fleck patterns on its quartersawn surfaces, but it’s generally just not quite of the same caliber and size as white oak. (See this quartersawn picture of red oak for reference.)

Oak lumber: Superficial color differences

While there is one specific wood species (Quercus alba) that’s commonly considered the “white oak,” and there is one specific species (Quercus rubra) that’s considered the “red oak,” when you buy oak lumber within North America, oftentimes you will not actually be buying these two exact species, but instead you may be buying one of the oaks contained within the two broad red and white groupings. Basically, you’re buying characteristics found in an oak group, and not necessarily an exact species. For the rest of this article, I’ll be referring to red oaks and white oaks (plural) as two different groups of trees, and not simply as individual species.

At a casual glance, unfinished oak lumber will generally be light brown, either with a slight reddish cast (usually red oak), or a subtle olive-colored cast (white oak). However, there are abnormally light or dark outliers and pieces that are ambiguously colored, making separation based on color alone unreliable—this is especially true if the wood is finished and/or stained.

Nonetheless, it can be helpful to get a baseline view of the typical color that’s seen in red and white oaks. Listed below are small thumbnails of various oak species in their raw unfinished form, arranged in either the red or white oak grouping. Comparing the two groups is simultaneously helpful and also confusing. You’ll notice that there’s a general categorization of color that most samples fall into (helpful), but you’ll see that there’s also no hard and fast rule to easily tell the two groups apart by color (that’s the confusing part).

Red oak group

Looking at the examples above, you may notice a loose pattern where red oak species tend to have a slightly paler and redder hue on average, while white oak species have a slightly more olive hue. There are of course outliers and individual variation from tree to tree, so the above grain samples should by no means be meant as an accurate representation of any of the species as a whole.

But realistically, even if you can discern a pattern in the red/olive dichotomy of oak coloration, you can hopefully also see how much overlap and unpredictability there are between pieces.

Tips for actually telling red and white oak apart

In most cases, we won’t have access to the tree or its leaves, so all we have to go on is the wood itself. Here are some ways of telling types of oak apart that tend to be a little more reliable than using color alone.

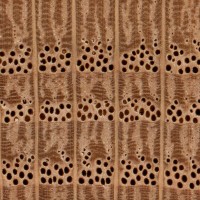

1. Look at the endgrain

A quick and fairly reliable way to tell the two oaks apart is simply by looking at the endgrain. In order for this to work, the ends of the board can’t be painted, sealed, or rough-sawn. A freshly cut oak board should be easy to distinguish:

The pores found in the growth rings on red oak are very open and porous, and should be easily identifiable. White oak, however, has its pores plugged with tyloses, which help make white oak suitable for water-tight vessels, and give it increased resistance to rot and decay. The presence of tyloses is perhaps the best and most reliable way to distinguish the two oaks, but it comes with a few caveats:

1.) Make sure that you’ve cleaned up the endgrain enough to see the pores clearly, and blown out any dust from the pores. You don’t want a “false-positive” and mistake sawdust clogged in the pores for tyloses.

2.) Make sure that you’ve viewing a heartwood section of the board in question. While white oak has abundant tyloses in the heartwood, it is frequently lacking in the sapwood section.

One related test regarding porosity is to take a short section of oak and try to blow air through the pores. If you are able to blow anything through it at all, it’s probably red oak. Take a look at this video, where a red oak dowel was used to blow bubbles in water:

One exception to this rule is chestnut oak, which is still considered to be in the white oak group, even though its pores are open like red oaks.

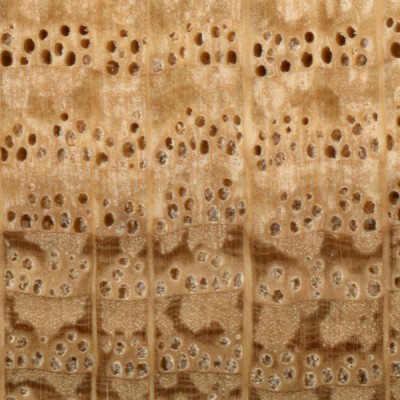

2. Look at the rays

When looking at the face of the board, especially in the flat-sawn areas, you may notice little dark brown streaks running with the grain, sometimes referred to as rays.

Look closely at the picture above, (click on it to enlarge it if you have to), and note the length of the rays in both types of wood. Red oak will almost always have very short rays, usually between 1/8″ to 1/2″ long, rarely ever more than 3/4″ to 1″ in length. (Pictured above on the right.)

White oak, on the other hand, will have much longer rays, frequently exceeding 3/4″ on most boards. (Pictured above on the left.)

This method is probably the most reliable under normal circumstances, and is useful in situations where the wood is in a finished product where the endgrain is not exposed.

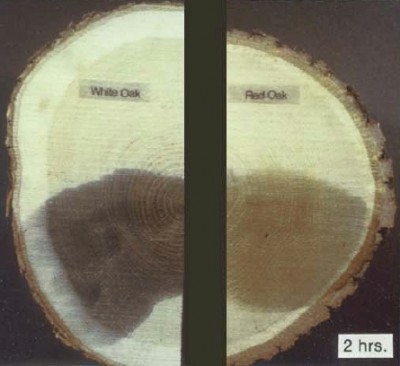

3. Use sodium nitrite

This technique is sometimes used at sawmills if various logs need to be sorted out quickly. Instead of taking the time to analyze each log closely by hand, a 10% solution of sodium nitrite (NaNO2) is sprayed or brushed onto the wood and observed. If it’s red oak, there will only be a small color change, making the wood only slightly darker. But if it’s white oak, there will be a noticeable color change in as little as five minutes, (though it can take longer if the wood is dry, or if the temperature is low). The heartwood of white oak will eventually change to a dark indigo to almost black.

This method is extremely accurate and reliable, though in most instances, it’s probably overkill. However, if you’re ever in a situation where you can’t separate between red and white oak based on anatomy, this method is nearly foolproof. (Though, only the heartwood will bring about the color change, not the sapwood.)

First, you have to obtain some sodium nitrite (NaNO2). You may be able to find some locally through chemical supply stores, but they typically only sell in bulk quantities, making such a small project prohibitively expensive. However, some online retailers have the chemical for sale in much smaller quantities, bringing it into reach of most that are curious about oak identification.

Next, you need to mix up a roughly 10% solution of sodium nitrite by weight. This ratio actually isn’t as critical as it seems: solutions as small as 1% and as high as 20% have all been used with success, but to err on the side of caution, we’ll use the most appropriate quantity recommended.

Recipe for 10% Sodium Nitrite Solution for Testing Oaks:

- 1 cup water

- 4 teaspoons sodium nitrite

Directions: Stir in sodium nitrite until clear. Clearly label solution to avoid confusion; sodium nitrite is very dangerous if ingested.

All that’s left is to simply brush this solution onto a raw wood surface and wait for a reaction. With dried wood stored at room temperature, this reaction should take about 10 minutes. Red oak will be only slightly discolored by the solution, sometimes developing a slightly greenish hue, while white oak will gradually turn a dark reddish brown, eventually turning a deep indigo to nearly black.

See the progression photos below for a better look. (Also note that around the 8 and 15 minute marks the water begins to evaporate from the surface of the wood, but the color is still present after the wood has dried, as indicative of the 25 minute photos.)

TIME | RED OAK | WHITE OAK |

| raw |  |  |

| 1 minute |  |  |

| 5 minutes |  |  |

| 8 minutes |  |  |

| 15 minutes |  |  |

| 25 minutes |  |  |

Why you’d want to tell red oak from white oak

As to the reasons why you’d want to be able to distinguish between the two, most of the answers have been explained above, but I’ll recap:

- White oak is much more resistant to rot, and is suitable for water-holding applications, boatbuilding, outdoor furniture, etc.

- Red oak should only be used for interior pieces such as cabinets, indoor furniture, flooring, etc.

- White oak tends to be more dense, while red oak is a bit lighter and has a more porous and open grain.

- White oak is usually slightly more expensive than red oak.

- White oak has larger and more pronounced ray flecks when perfectly quartersawn and historically has been used more often in antiques than red oak.

Get the hard copy

Hi can someone please help me with identification…..

Red or white oak. There are two samples next to each other….

Warm regards

Top looks like white oak the bottom looks like ref oak. To me anyway.

Can some one tell me if this is red or white oak? I think it’s red oak, but the reading about the rays it made me second guess.

Red oak

Thank you for very good information.

Can i use white oak for cutting boards?

Hello experts! I’ve got partial oak hardwoods in my main level. I plan on taking out the carpet, and finishing off the hardwoods. Then refinishing everything to a darker color. Looking for some expert guidance on if my existing hardwoods are Red or White oak! Appreciate any help! Steve

Looks like white oak to me based on the ray length.

Thanks so much!

Can somebody help me determine if this is red or white oak?

Trying to mix a custom stain for our stairs and railing – can you tell if this is red or white oak?

I can’t tell from that distance, sorry.

How about this pic?

Hard to say for sure since it appears to be stained, but judging by the longer rays on the perfectly flatsawn portions, I’d lean more towards white oak.

Okay, thank you!

Can you tell me what species this piece of wood is?

Hello,

I have a 1920’s machinist case that I have been restoring, I think it is white oak but not certain. Any idea?

almost certainly white oak based on the photograph and the date of the case.

Hello! I am wondering if this piece of furniture is made from red oak? I have attached a picture of the piece, which has been sanded. Thank you!

No, that’s not oak. It looks like a type of yellow pine to me.

I have been give a load of what I was told is English Oak. As the photo shows, there is a lot of sapwood and I shall follow your advice on how to determine red vs white. I intend to make bowls and a few stool legs out of this lot and I get conflicting opinions on how to deal with the sapwood. Knowing exactly what I have, in terms of red/white will make it easier to make sense of opinions offered. I live in Melbourne, Australia and have never had a piece of green oak to work with and… Read more »

I can’t tell from your picture — you would need to get much closer to the wood surface, and also finely sand the grain in order to make out more details. However, if it is truly english oak, then it should be treated as being in the “white oak” group.

…On further inspection, I’m wondering if in old houses, (1910) they used mixed hardwoods?

Hi,

My installer/re-finisher swears both of these are white oak.

I suspect the older flooring, to the right is red oak.

Both have one coat of poly on them.

Can anyone tell me what the flooring on the right is?

Thanks very much.

Can you please tell me if the existing floor is red or white oak? I can’t figure it out even with all the methods.

Red oak

I was going to say it’s definitely White Oak based on the boards with mixed darker heartwood and lighter sapwood typical of White Oak. A few boards look like Red Oak though. Closer pictures would be required for a better guess.

We wrote a article about OAK, somebody can read and fix if i loss something a bout Oak. This the best wood i like

https://tubephaphuong.com/tin-tuc/go-soi-la-gi-go-soi-co-tot-khong-go-soi-gia-bao-nhieu–114.html

Is there a simpler solution to distinguish these two types of wood?

Thank you for helping me distinguish these two types of oak!

We are looking to match the wood flooring in existing home into kitchen to keep open floor plan flow. They are saying that the existing wood floors, which are beautiful but 55 yrs old, will match the attached sample over time. We dont want to stain to match. Is this true? If so, how long will color change take…

My client complains that it is impossible to distinguish between the two types of oak. This could be a great suggestion for us

Hi, I think I have red oak. I’m going to stain it, and I don’t want to see any hint of red after I stain. What color stain would work best at hiding the red? I’m thinking about a grey stain with a white wash on top, your thoughts?

Hi Debbie. Earlier this year I had a client who wanted the same thing–she had an older table top in a dark oak and she wanted a base made for it which would match color and grtain, but without a hint of red. I used red oak with Minwax Early American stain, and it was a perfect match. This combination may work for you.

Jim

This has helped me somewhat, although, I’m still unsure as to which floor I need to purchase to match my existing. I know it’s Oak 3/4″ thick, 2 1/2″ slats. I believe it’s white oak…

I’d appreciate it very much for you to review my photos and give me your expert opinion.

Thank you,

Donna

Red Oak. I make hardwood floors for a living. You are welcome :)

Can you tell me what this floor is? I really can’t figure it out even with all the help on here…Thanks, I would really appreciate it!

Assuming that the color on your camera is accurate, it looks like red oak to me.

Excellent article. We are trying to separate several 1,000’s board feet of long dried specimen oaks from central NJ near the ocean, and all our highly skilled cabinetmakers, are having trouble discriminating. We almost never use red oak, but in the past have seen indisputably white oak species wood, that had a strong red cast to it. Looking forward to trying the sodium nitrate. Thank you!

Remember, it’s sodium NITRITE, not nitrate !

Here’s a clip for a fast and easy way to separate the two: https://youtu.be/L6t2AZubF8U

Sorry if this has been posted earlier. I haven’t looked through all the other comments.

Thanks-this guy is great!

Thank you for very good information.

Can i use white oak for cutting boards?

While the wood itself is not toxic (some wines are aged for months in oak barrels), the rough texture of the wood will trap tiny amounts of blood, fat, everything. I wouldn’t recommend it. I’d look for another wood. In a holiday camping situation where you needed to prepare food on some surface and all you had was a white oak board to use, it’s probably fine for one time use as long as you do all your food preparation on it in a very short time and avoid cross-contamination by not cutting up vegetables for salad after chicken and… Read more »

I just milled some red oak that was cut over 10 years ago . There is some rot 12″” from the butt end however there is a beautiful green stain going from the butt end up 3-4′ and almost from side to side. Is this stain from the rot or is it from something else ?

Yes, that’s oak!

I have salvaged oak beams that I would like to use for flooring. Is it best to use the white oak only or can they be used together?

It depends on if you are planning on staining them fairly dark, or leaving them natural colored. On average, red oak and white oak will look visibly different when placed next to each other. (The James J Hill house in St. Paul actually uses red and white oak flooring as subtle contrasts to one another.) So, unless you plan on coloring the wood fairly dark to hide the color difference, I say don’t mix them.

what are alternatives to oak in barrel making

Well, the classic approach to making Chianti involves aging the wine in chestnut barrels.

can we use teak for whisky barrel making.

An old man gave me a really good method of remembering the leaf differences in red and white oak.. Red Oak leaves are pointed like the Red Man’s arrows, White Oak leaves are rounded like the White Man’s bullets….I have shared this with many over the years and it’s always remembered! Great site, thanks for all of the work.

Jerry Honeycutt

I have 5 white oak trees 150-200+ years old that need to be taken down. Is there any value in the wood?

Use the smell test: red oak(s) usually have a sour smell when cut, white oak(s) have a herbal or nut-like aroma when cut. Smell disapates soon, have your nose readily available. A good clean cut with a miter saw also allows viewing the end grain

In which orientation would one want the growth rings in relation to the edge of a piece of white oak in order to maximise impact resistance? I understand that the idea is to have as many fibres as possible on the impacting surface to spread the force but reliable way to determine this by examining the growth rings/rays/etc is eluding me. Having tried to find definitive description of how to determine this online I’m coming away feeling more confused than before I started… any help would be greatly appreciated and might just save my sanity! I’ve attached 5 (poor quality… Read more »

Rightmost is best. Second is worst. Just recall a baseball bat, where you swing with the label up. The label is always on the side that has concentric ring shapes.

P.S. I can’t quite tell where the grain is in the middle one.

I have been trying to

identify the type of oak used on a table that has been in my family

since the 1920’s. I have been told it has a rare natural marbeling (as

seen in the picture)from the guy who refinished it for me. I appreciate

any input given. Thank You.

Stephanie,

It’s hard to tell from the picture, but I can say that antique furniture was very frequently made using quartersawn white oak. That’d be my first guess on a piece such as this.

I agree. I work in quartersawn oak everyday. (shaker boxes). That’s exactly what it looks like.

It’s old growth quartersawn white oak. Growth rings are very tight on this. Most likely from virgin forest.

Looks like tiger wood. Not certain, just saying.

Na

Gorgeous table.. almost looks burly

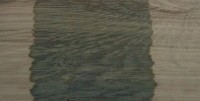

An alternative to the Sodium Nitrate solution is to drop some of that steel wool you’ve undoubtedly got in the shop in to some vinegar, let it sit for a while, then you can wipe that on white oak and you’ll have your black. It reacts with the tannin in the wood pretty darn quickly so you may not even have to wait a minute to see results. The ingredients are also a fair bit easier to get and quite safe. The attached image shows what to expect after a minute on a dressed surface. You can see it happen… Read more »

Doesn’t distinguish between wood types. They’ll both turn black. Try again

I have a huge beam twenty foot long approximately 12″ by z12 hand notched pegged together. Washed up in my creek I have found several other beamms upbthe creekm I have been told they are from early 1800 any value in the wood for reclaimed wood

Not too much of commercial value in the beam but integrating it into a project in your home, shop, garden would be a great way to salvage a piece of history along with the story of finding it!

Question: A friend has some red oak for sale. It was salvaged from a courthouse in Florida. Not sure of age or how it’s cut. Haven’t seen it yet; just a pic. Any idea what it’s worth per bf?

In which orientation would one want the growth rings in relation to the edge of a piece of white oak in order to maximise impact resistance? I understand that the idea is to have as many fibres as possible on the impacting surface to spread the force but reliable way to determine this by examining the growth rings/rays/etc is eluding me. Having tried to find definitive description of how to determine this online I’m coming away feeling more confused than before I started… any help would be greatly appreciated and might just save my sanity! I’ve attached 5 (poor quality… Read more »

Doug, you can buy dyes for wood. Are the bowls you plan to turn for food ? If so you may wish to use something other than oak or any other open grained wood.

Hi all,

I recently was given a quantity of 2″+ rough sawn red oak, at least from the visual tests here it appears to be red rather than white oak. It’s dry, been in a garage for 20 some years.

I want to turn shallow bowls with it.

My question is, are there any methods of dying it near black with common household solutions like the steel wool on white oak?

Thanks, Doug

Doug

Did you try India ink?

@ Carl/Maddie: I’d be extremely surprised if it turned out to be a wood as obscure as Monkeypod. It doesn’t appear to be an entirely natural wood color, I suspect it’s stained. It lacks the conspicuous rays that you’d expect to find on oak, even on the flatsawn surface. The grain pattern does look reminiscent of mahogany and its myriad lookalikes.

This is a classic example of trying to pinpoint an ID with insufficient information! See the article on “The Truth Behind Wood ID” especially the section “think you’re a know-it-all?”

https://www.wood-database.com/wood-articles/the-truth-behind-wood-identification/

Maddie,

It is somewhat hard to tell from the picture but it appears to be very similar to Monkeypod. The picture on this site for “sealed” monkeypod has pores that appear to be the same.

I have pics of a dresser but not quite sure of the wood. Could you help me?

I read somewhere that red oak roof shakes last a long long time if strapped properly because it lacks tylosis. My guess is that it being ring porous allows the shakes to dry out faster and maybe the tannins repel certain fungis as well just guessing though.

Very interesting site. I didnt know others were as so interested in wood technology as myself. Keep up the excellent work. I know now where to go if my memory fails me, although I always have DESCH on my book shelf. Regards David.

I looked at a larger version of your picture, and it seems that a pile of wood I found curbside had a very similar grain character. The finish was also very much like that yellows and reds in your picture. I estimated the furniture age of what the boards used to be in as about turn of the century, up to 1925 or so. I have never known of this stuff to be called anything other than quartersawn white oak, tiger(stripe) oak, or sometimes just white oak or even just oak.

We are planning to replace our carpeted stairs with unfinished oak “retro-treads” which we hope to stain and finish to match our finished oak floors. The retro treads come in both unfinished red oak and white oak and I’m not sure which to order. Our house was built in 1955 and the wood floors are original to that time, although we had them sanded, stained and polyed when we moved in 27 years ago and they still look great. Do you think our floors are likely to be red or white oak? Could either the red oak or white oak… Read more »

Possible types of wood

(1) Zygia racemosa (syn. Marmaroxylon racemosum, Pithecellobium racemosum) of the family Leguminosae (aka Fabacea) (subfamily Mimosoideae), the legume or pea family

(2) Diospyros marmorata of the family Ebenaceae

Stephanie,

It’s hard to tell from the picture, but I can say that antique furniture was very frequently made using quartersawn white oak. That’d be my first guess on a piece such as this.

I have been trying to identify the type og oak used on a table that has been in my family since the 1920’s. I have been told it has a rare natural marbeling (as seen in the picture)from the guy who refinished it for me. I appreciate any input given. Thank You.

Thanks for all that good info. I am a woodturner(11yrs) & harvest most all of my owwn wood. Additionally I have noticed that some Reds may have a rounded looking lobe but will have a needle point on the tip of the leaf.

An alternative to the Sodium Nitrate solution is to drop some of that steel wool you’ve undoubtedly got in the shop in to some vinegar, let it sit for a while, then you can wipe that on white oak and you’ll have your black. It reacts with the tannin in the wood pretty darn quickly so you may not even have to wait a minute to see results. The ingredients are also a fair bit easier to get and quite safe. The attached image shows what to expect after a minute on a dressed surface. You can see it happen… Read more »