by Eric Meier

So, you want to make a cutting board out of wood (or woods), and you’re wondering what’s best. A lot will depend on your individual preferences, and what you’d trying to accomplish. I’ve broken this question down into two components:

1) Mechanical performance and longevity

2) Sanitary properties and safety

3) Specific recommendations (and rankings) of common cutting board woods

Mechanical properties and longevity of cutting board woods

When it comes to desirable properties for a wood used in a cutting board, it’d be hard to beat the usefulness of Janka hardness. While this doesn’t technically measure abrasion resistance such as would be encountered when a knife is passed over the wood surface (it actually measures the wood’s resistance to indentation), it’s still a very close proxy and is the most widespread and relevant test for our purposes here.

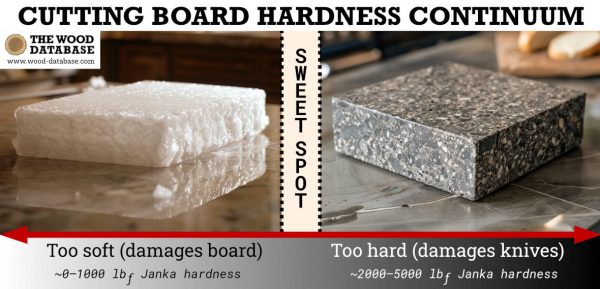

For cutting boards, most people would agree that there’s a happy medium between being too soft (and being excessively damaged with each successive knife cut) and too hard (to the point that the knife is dulled). Picture a block of styrofoam, contrasted with a slab of granite—there’s a hardness continuum.

On the soft side, some woods are too easily damaged and won’t have a long service life as a cutting board. While there is no black-and-white cutoff from the minimum Janka hardness value, in general, any wood with a value below 1000 lbf (4,450 N) will start to show signs of wear faster than most would deem acceptable. I prefer to think of it as a gradient, where values above 1000 lbf are increasingly resilient, and the further below 1000 lbf any given wood’s hardness is, the more prone to scratches and damage it will be.

On the other end of the spectrum are woods that may be considered too hard and cause knife blades to dull too quickly. For simplicity’s sake, I find it easiest to just set this number at around 2,000 lbf (8,900 N) Janka hardness. Of the two bounds, this upper bound is definitely the more subjective of the two. Also, it will pay to check each prospective wood’s profile page for silica or other mineral content (found in the “Workability” section for each wood) to see if there may be other dulling effects that aren’t directly attributed to the wood’s hardness.

A lot will depend on the intended end use; if you’re making a cutting board for yourself, you’ll have the greatest leeway. Maybe you have a fancy knife sharpener and don’t mind resharpening your blades from time to time. Or maybe you know this project will only be used as a serving tray and you’d prefer to keep your options open to the most aesthetic/figured wood options available.

Thus far, without taking any further characteristics into account, you can use the Wood Filter tool to list all woods with a Janka hardness between 1,000 and 2,000 lbf—sorted by hardness.

Sidenote: End Grain Cutting Boards

In addition to each species and its Janka hardness, one last variable to consider is using endgrain for the cutting board vs face grain.

Referring to the cutting board hardness continuum graphic above, using endgrain for the cutting board has the effect of sliding softer woods farther right on the spectrum—basically making them more resilient to damage from knives—while still maintaining a relatively mild impact on cutting edges. It’s the best of both worlds.

Try to picture the structure of wood almost like a bunch of straws. If a knife passes over them lengthwise, it will cut across the surface of the wood fibers, and the wood will, in general, sustain more and deeper damage. By contrast, if a knife is cut across the ends of the straws (an approximation of what happens with an endgrain cutting board), then the straws (or wood fibers) will only temporarily be pushed out of the way, and the wood surface will receive less damage. Endgrain cutting board surfaces are in effect almost self-healing.

Of course, endgrain cutting boards are more labor intensive to make, and usually require multiple smaller pieces to form an adequately sized cutting board. But if you’re planning to make a cutting board that will be subject to heavy and repetitive use, the extra effort of using endgrain is well worth the effort and will almost certainly extend the usable lifespan of the cutting board.

Sanitary properties and “safety” of cutting board woods

When talking about cleanliness of cutting boards, it’s important to recognize two very different conceptions of “clean.”

Under-counter slide out trays can become a breeding ground for bacteria.

Clean and sanitary are two very different things

“Clean” is mostly just a feeling

Despite what our brains tell us, what we are usually after is just a “clean” surface